A shield screw conveyor dismantling device

A technology of screw conveyor and shield screw, which is applied in the field of shield screw conveyor dismantling device, can solve the problems of laboriousness, low safety, time-consuming, etc., reduce labor intensity and labor cost, improve the degree of mechanization, and improve mechanization The effect of level and degree of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

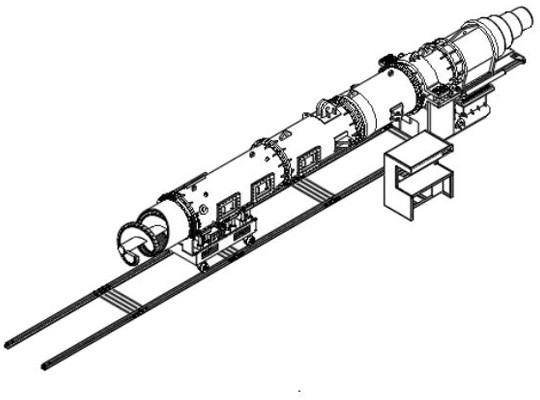

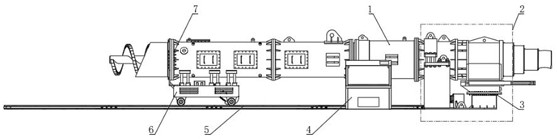

[0022] The present invention is further described in conjunction with accompanying drawing and specific embodiment:

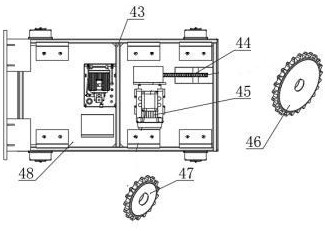

[0023] Such as figure 1 As shown, a shield screw conveyor dismantling device includes a shield screw conveyor support 2 , a guide rail 5 , a moving trolley 6 and a control platform 4 . The shield screw conveyor support 2 is placed at the tail of the entire dismantling device; the guide rail 5 is connected to the screw conveyor support front end guide rail connecting plate 22 by means of the middle support connecting bolt 25; the mobile trolley 6 is placed on the guide rail 5, the wheels 38 are used to contact the rail 21; the control platform 4 is placed on the left side of the dismantling device.

[0024] The shield screw conveyor support 2 includes a bottom plate 17, a screw conveyor support seat 19, a support upper cover plate 8, lifting lugs I11, lifting lugs II24, lifting lugs III18, lifting lugs IV23, rail connecting plates 20, Small pumping station I12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com