Full-automatic bicycle baffle plate punching device

A punching device and bicycle technology, applied in bicycle accessories, feeding devices, positioning devices, etc., can solve the problems of inability to meet large-scale market orders, no published patent documents, and high labor intensity, saving manpower. , the effect of high production efficiency and small safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

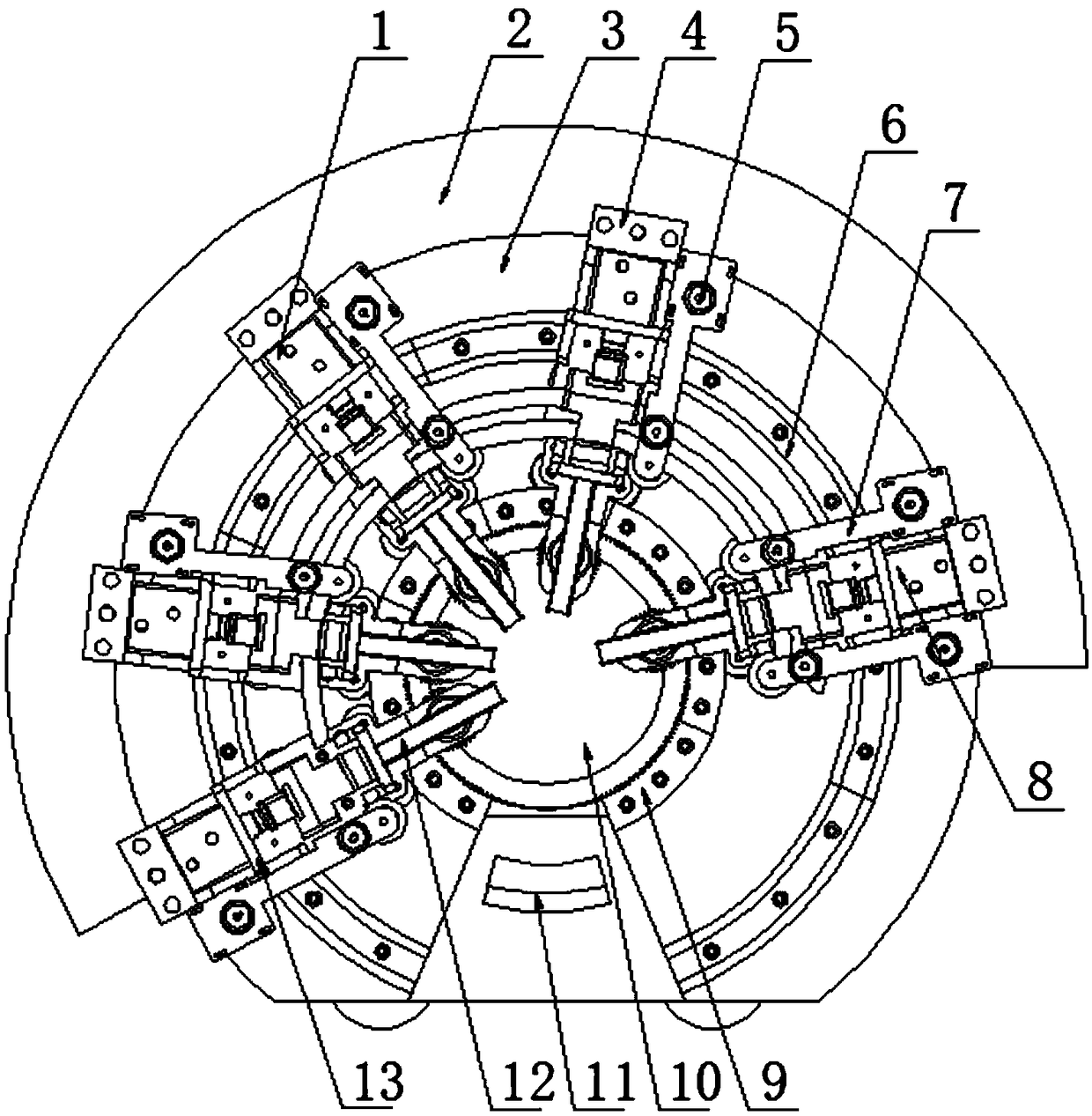

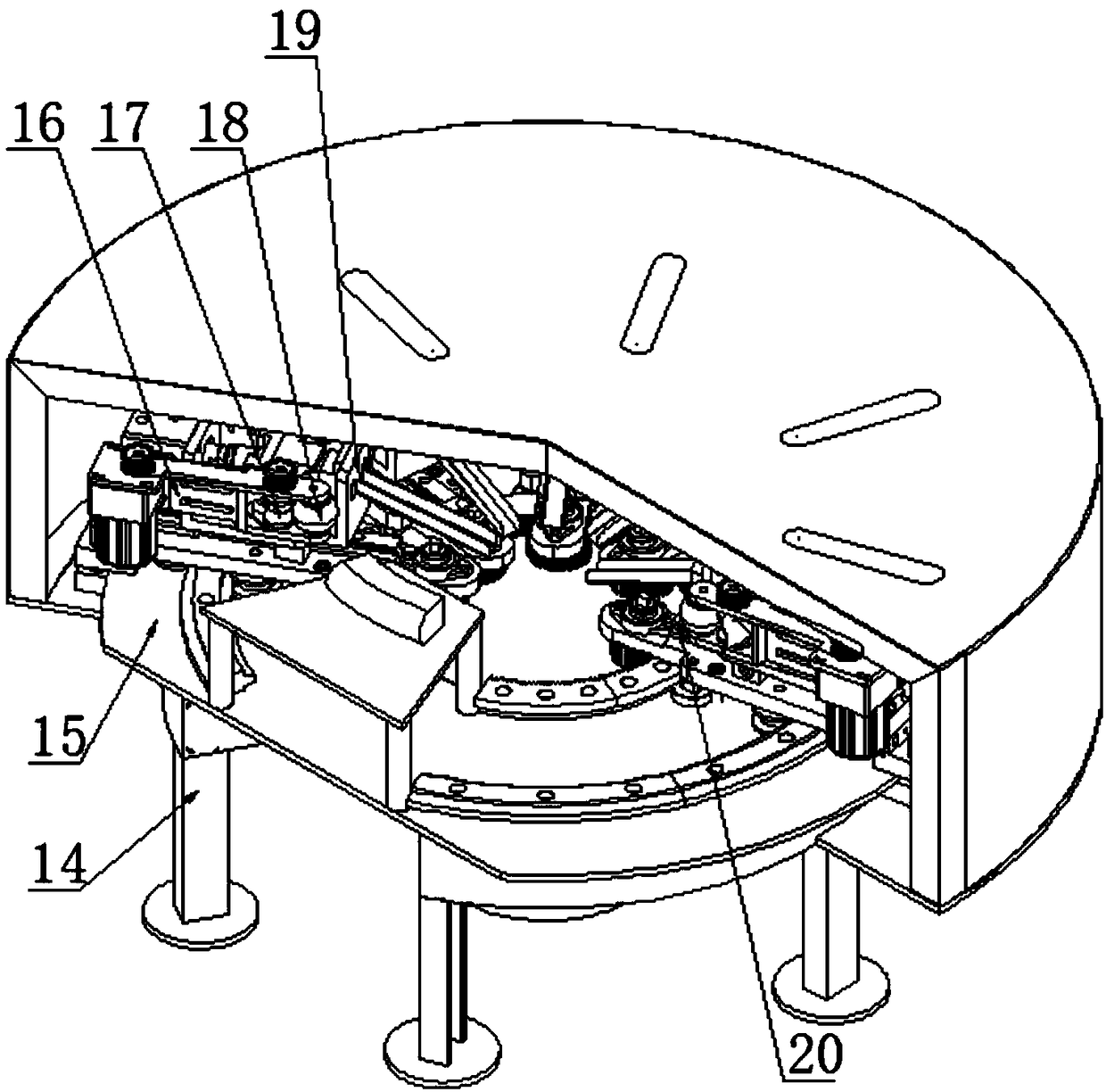

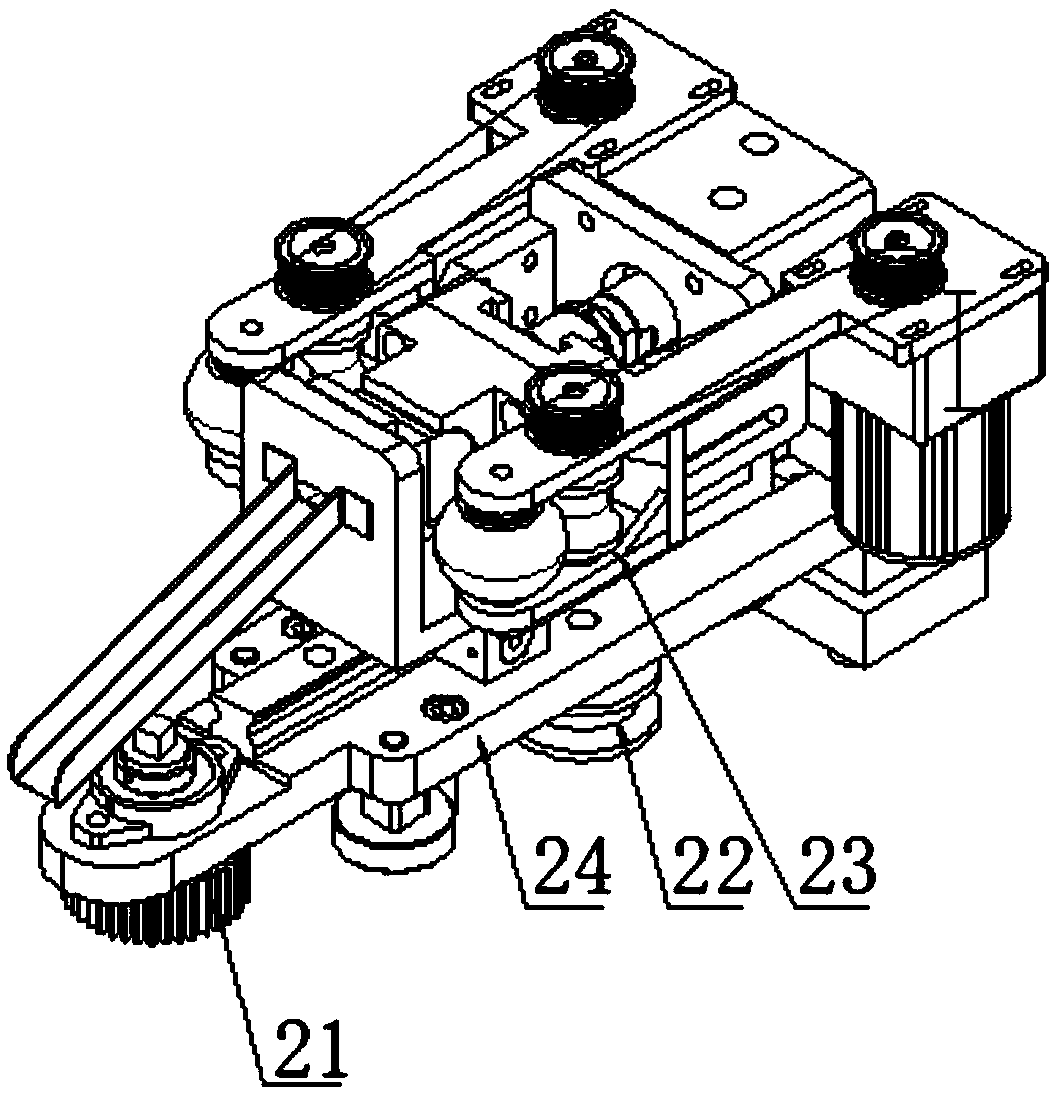

[0027] A fully automatic bicycle baffle punching device, the innovation of which is that it includes a support platform 3 and a punching mechanism 1 installed on the support platform, the support platform includes support legs 14 and a horizontal support plate 15, and the horizontal support platform is set There is a material placement platform 11, on the horizontal support plate, there are coaxially arranged waste material discharge holes 10, angle adjustment ring gears 9 and guide rails 6 in sequence from the center to the outside, and waste material receiving barrels are fixedly installed at the bottom of the waste material discharge holes, The hole mechanism includes a punching hydraulic cylinder 8, an L-shaped storage table 19 and a base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com