Small hole polishing method and device

A technology of grinding wheel and turning device, which is applied in the direction of grinding machine, grinding feed movement, grinding workpiece support, etc., which can solve the problems of time-consuming, laborious and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

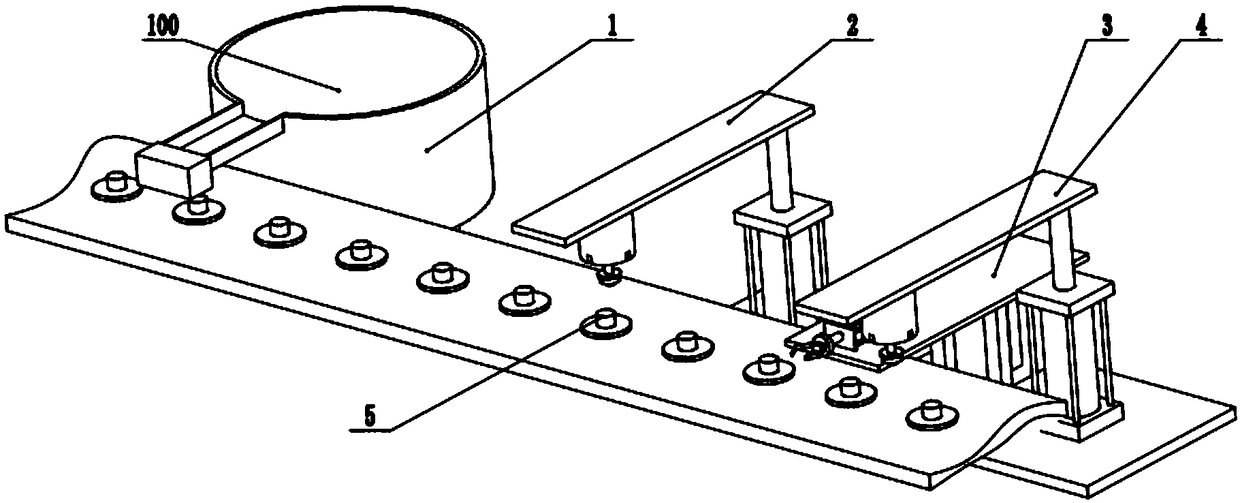

[0020] A small hole grinding device is composed of a feeding device 1, a front grinding device 2, a turning device 3, a rear grinding device 4 and a base 5. The front grinding device 2 is installed in front of the feeding device 1, and the front grinding device 2. An overturning device 3 is installed in front, and a rear grinding device 4 is installed in front of the overturning device 3. Below the front grinding device 2, the overturning device 3 and the rear grinding device 4 is a conveyor belt. The front grinding device 2 and the rear grinding device 4 are completely structured. Likewise, the base 5 is mounted on the conveyor belt.

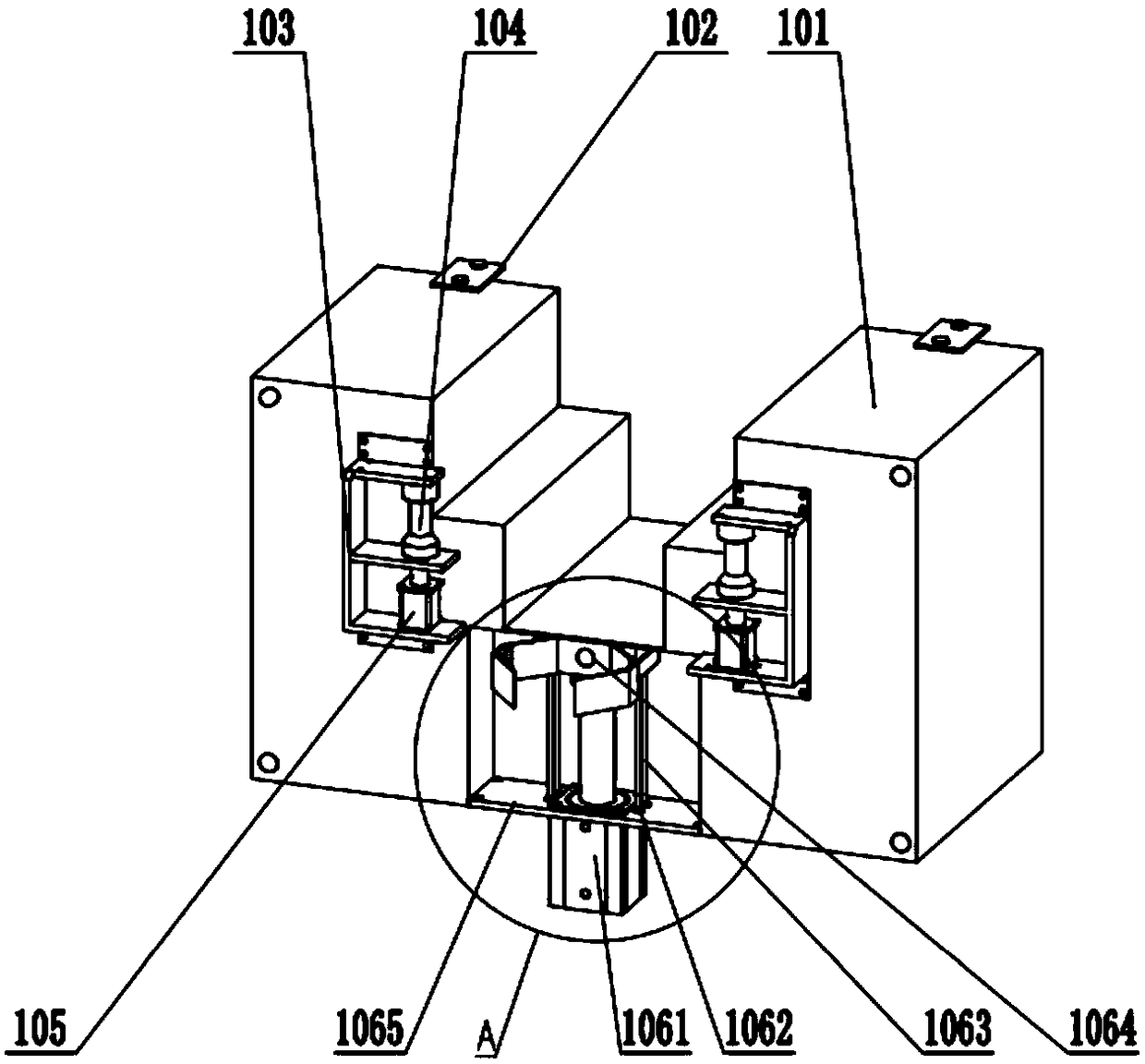

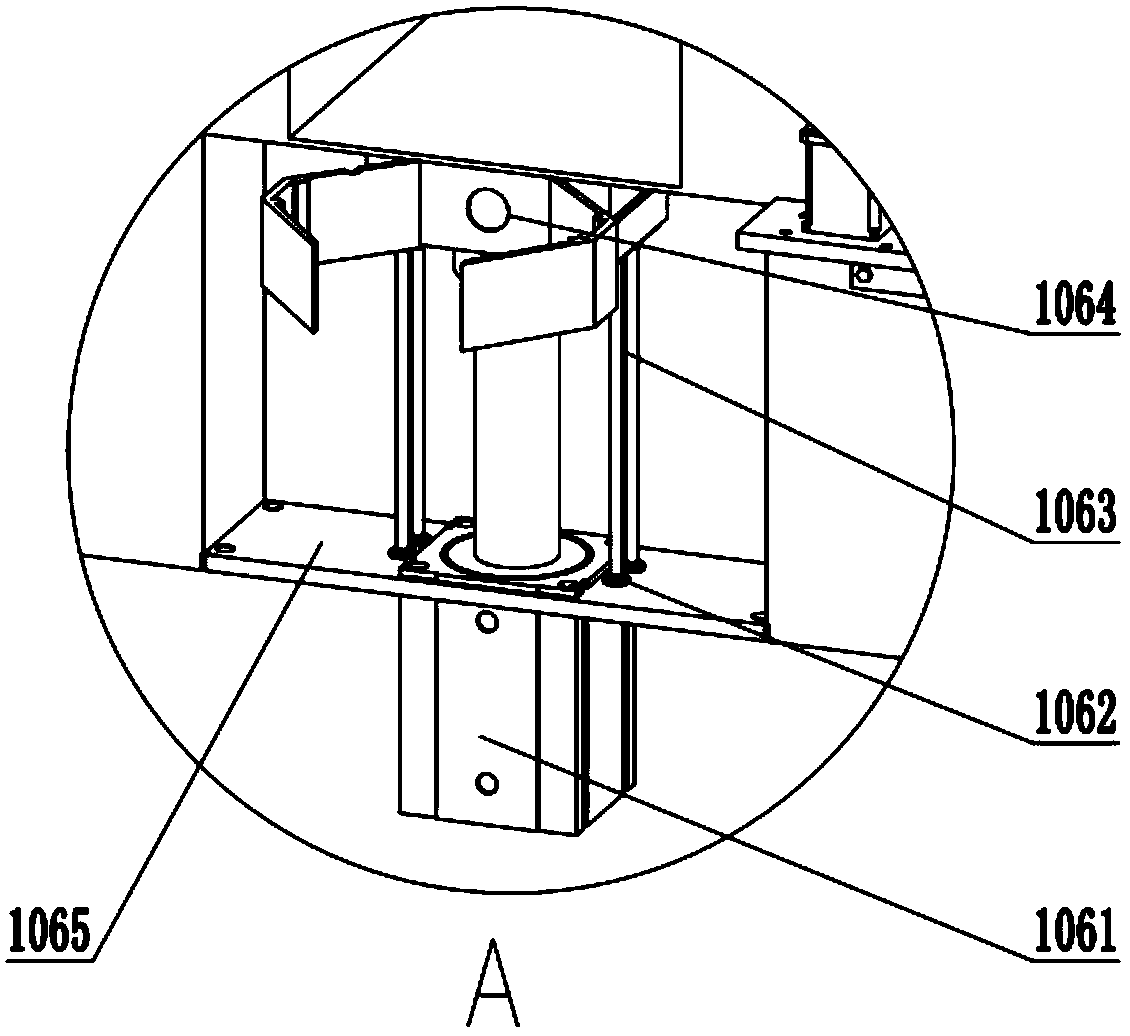

[0021] The feeding device 1 is composed of a vibrating plate 100, a discharge guide rail 101, a connecting piece 102, a bracket 103, a roller 104, a discharge motor 105, a small cylinder 1061 for picking up, a slide rail sleeve 1063, a slide rail 1062, a pick-up Composed of pneumatic gripper 1064 and lower support plate 1065, the discharge port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com