Multifunctional transfer device for to-be-pressed part of assembly and application method of device

A transfer device, multi-functional technology, applied in the directions of multi-axis trolleys, trolley accessories, transportation and packaging, etc., can solve the problems that cannot be stacked together, the battery sheet material is fragile and easily cracked, and the incidence of PID is reduced. The effect of improving component yield, reducing repair risk, and solving storage transfer difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

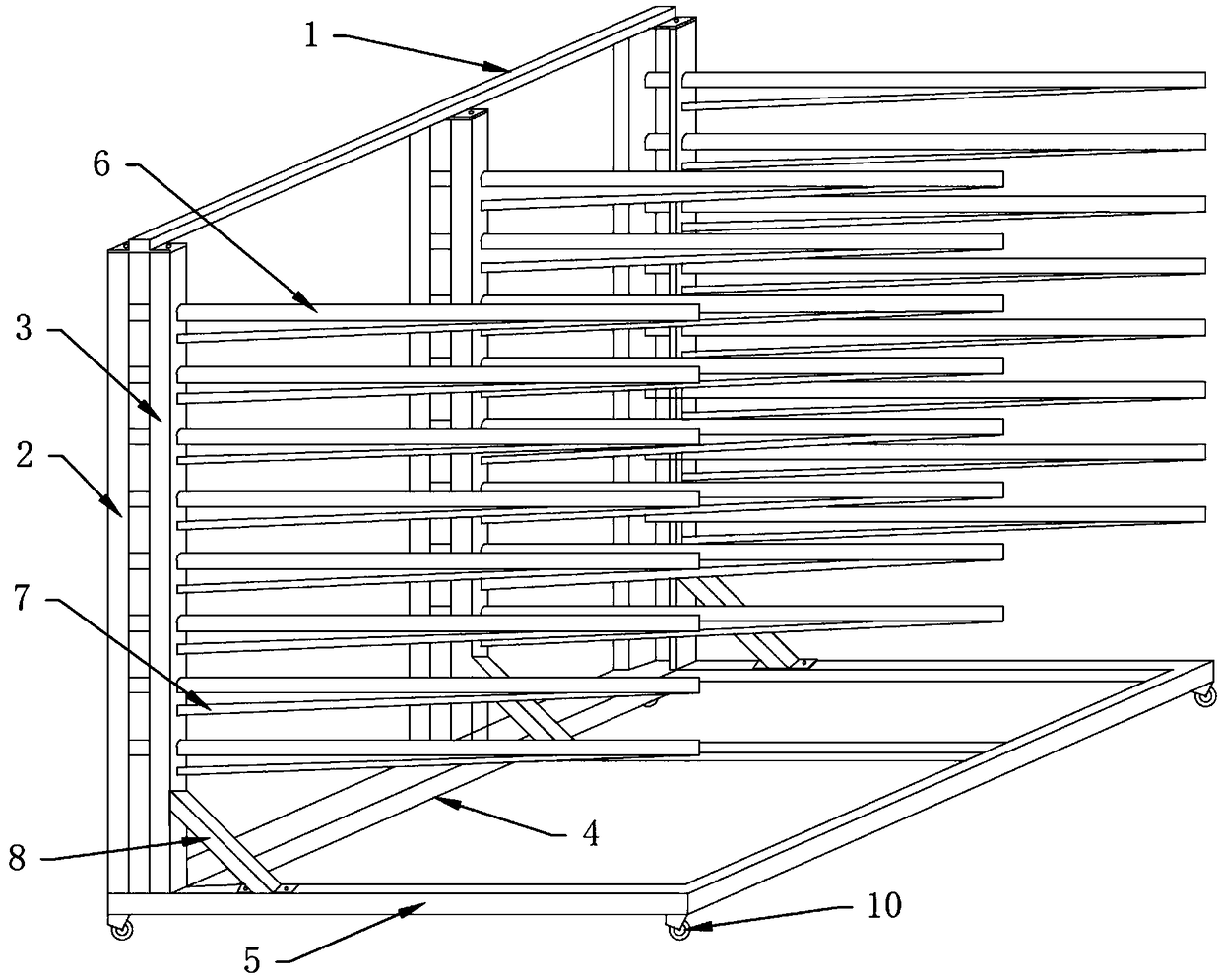

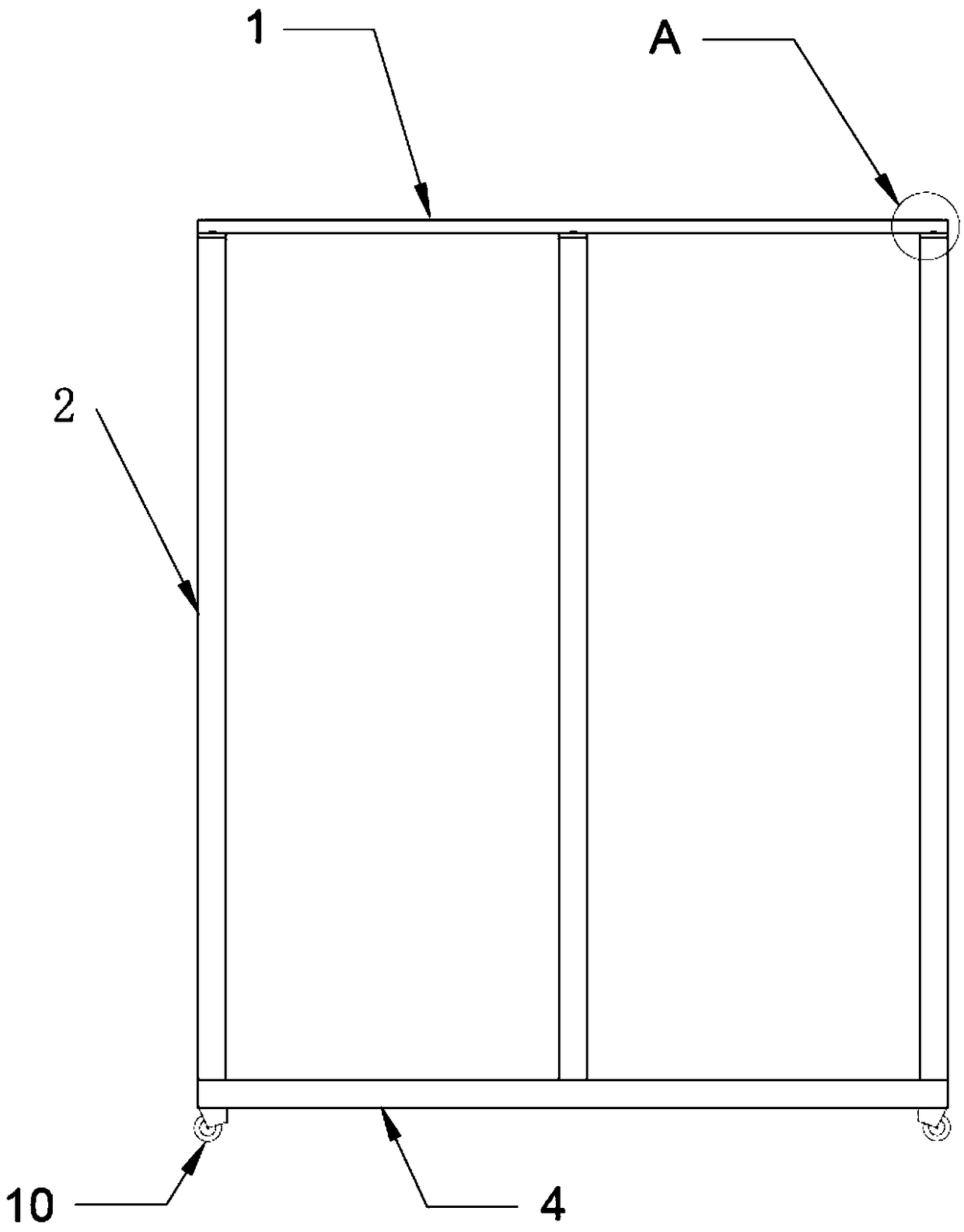

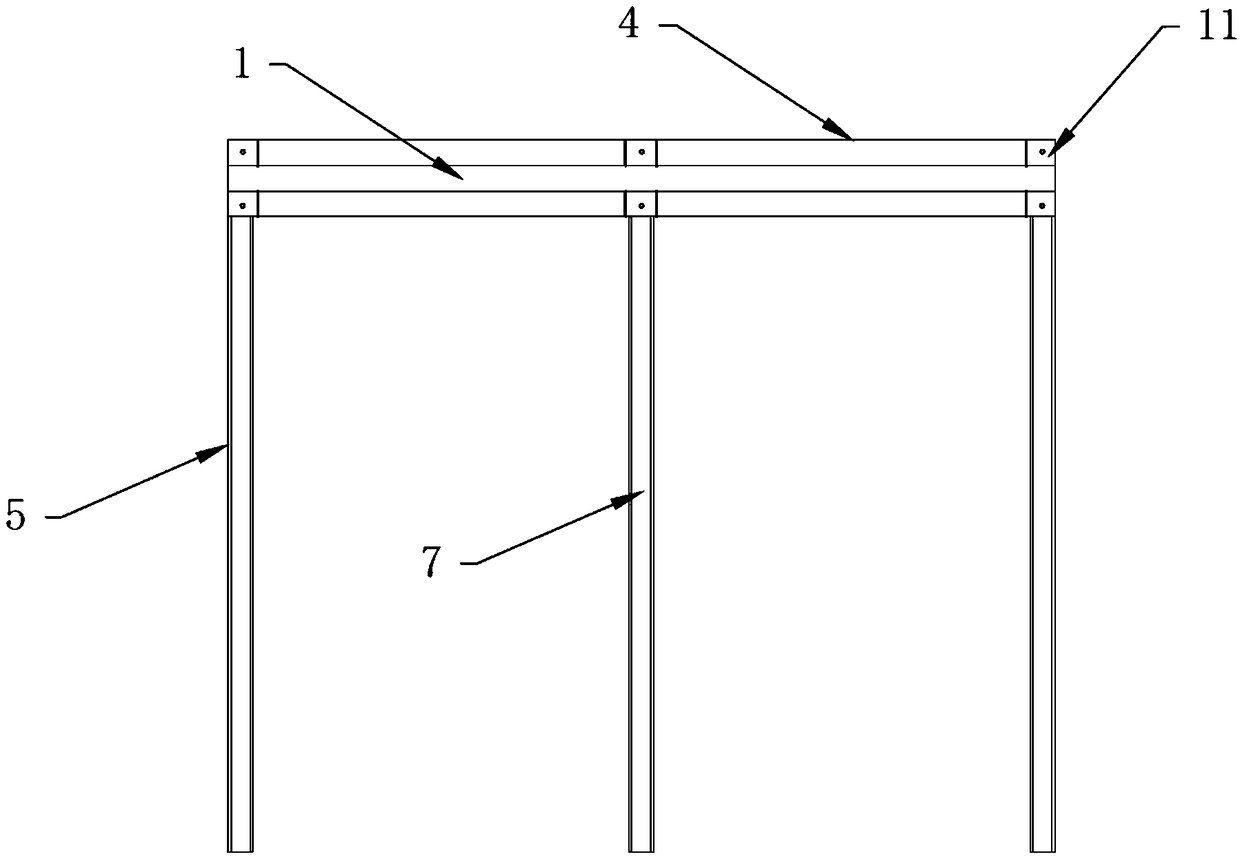

[0040] A device for installing multifunctional components to be pressed, comprising an upper beam 1, a set of lower beams, a set of supporting columns and wheels 10, the upper beam 1 and the lower beams are connected through the supporting columns.

[0041] The support column group comprises a rear support column 2 and a front support column 3, the rear support column 2 and the front support column 3 are arranged at intervals and the upper ends are all fixedly connected with the upper beam 1, and the upper beam 1 is a convex crossbeam, and the convex beam is connected by screws 12. Type crossbeam is installed on the support column group, and upper beam 1 both sides are fixed with mounting plate 11, and mounting plate 11 is fixedly connected on rear support column 2 and front support column 3 by screw 12 respectively.

[0042] The lower beam group includes two horizontal lower beams 4 arranged in parallel and a vertical lower beam 5 connected between the horizontal lower beams 4...

Embodiment 2

[0049] The difference from Example 1 is that, as described in the attached Figure 6 As shown, the supporting tube 6 and the reinforcing tube 7 are split structures, and only the protective layer 13 is wrapped around the supporting tube 6. The specification of the split supporting tube 6 is still a circular hollow structure of 8-15mm, and the reinforcing tube 7 It is a single 15-30mm square cross-section supporting slanted column, wherein the surface of the split reinforcing tube 7 is not provided with a protective layer, and only the upper surface of the ring of the supporting tube 6 is wrapped with a protective layer. Figure 12 And attached Figure 13 As shown, the support tube 6 is connected with a safety buckle 9 away from the front support column 3, and one side of the safety buckle 9 is fixedly connected with a bump 92. The form is installed in the ring hollow structure of the head of the support pipe 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com