Pipe tobacco compacting equipment for pipe tobacco encasement process

A shredded tobacco and equipment technology, which is applied in the field of shredded tobacco compaction equipment, can solve the problems of low utilization rate of shredded tobacco box and high transportation cost, and achieve the effect of compact overall structure design, saving space and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

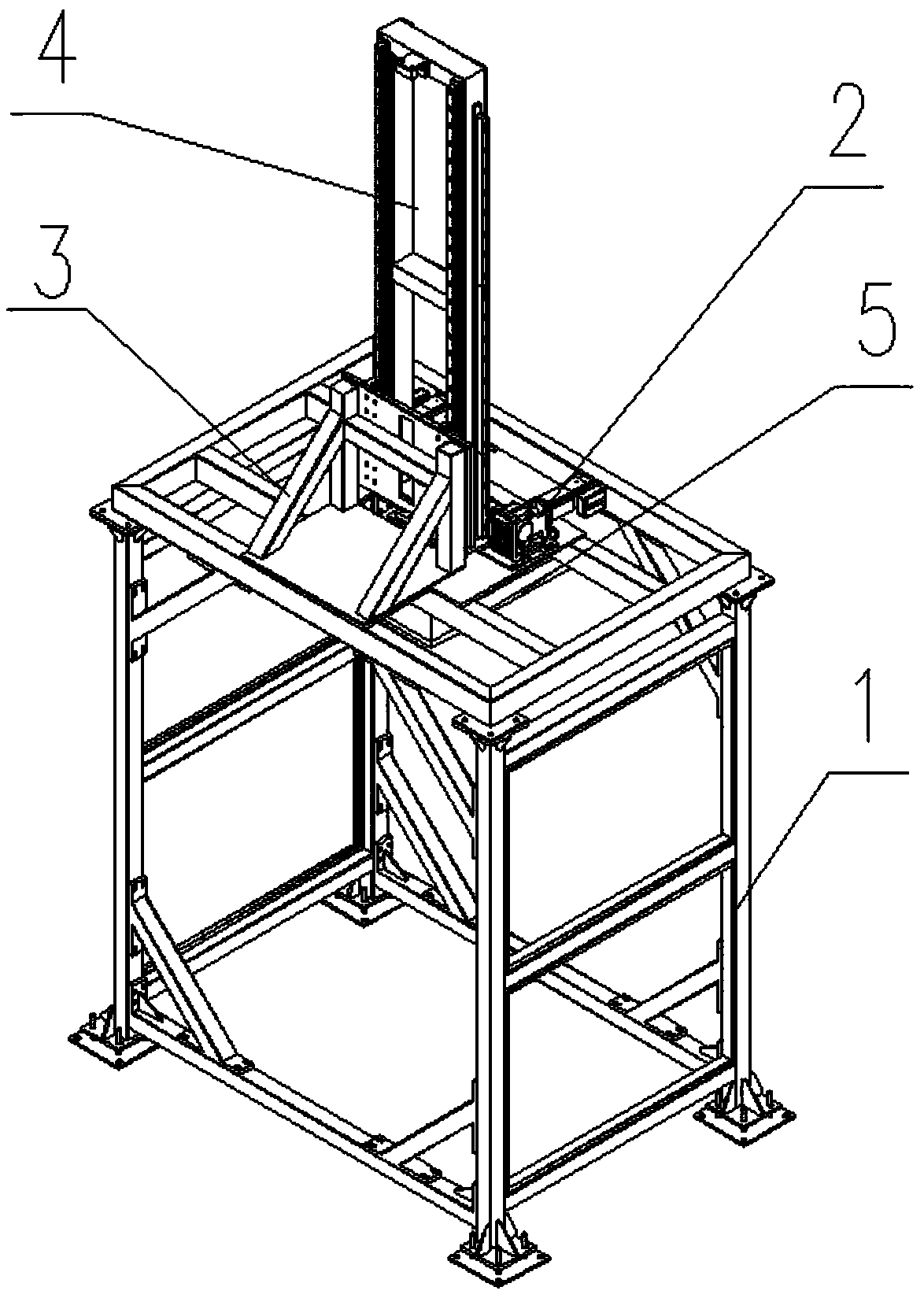

[0026] Such as Figure 1 to Figure 5 As shown, a shredded tobacco compacting equipment in the shredded tobacco boxing process includes a frame 1, a driving device 2 and a pressing device 4 installed on the rack 1, and a pressing head 5 installed on the pressing device 4.

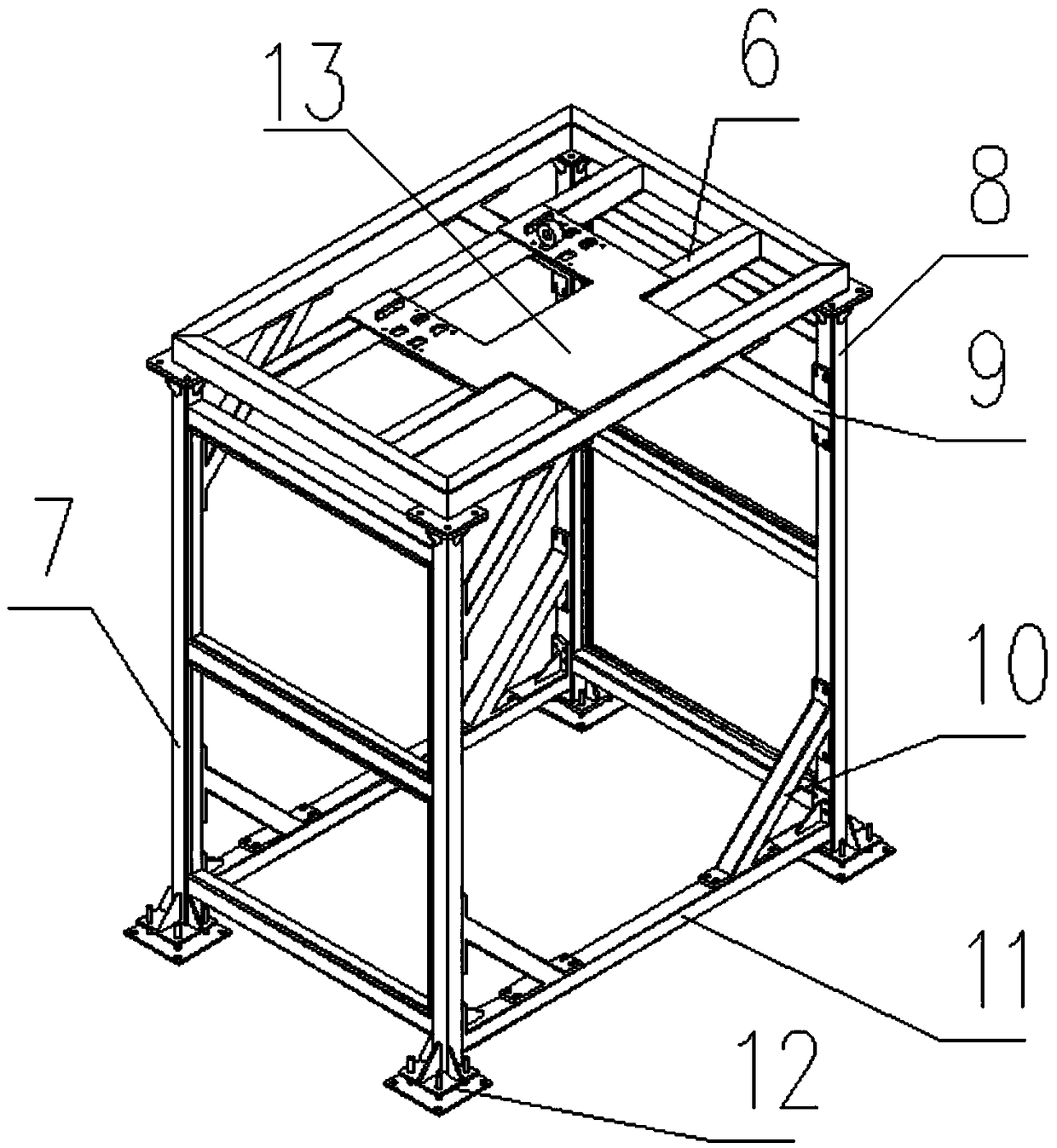

[0027] The frame 1 includes an upper frame 6 , a first side frame 7 , a second side frame 8 , an upper diagonal brace 9 , a lower diagonal brace 10 , a horizontal brace 11 and a bottom connecting seat 12 . The upper frame 6 is a whole welded by profiles, and is respectively connected with the first side frame 7 and the second side frame 8 by screws, and the left and right cross braces are installed between the first side frame 7 and the second side frame 8 by screws 11. A lower brace 10 is set between the cross brace 11 and the first side frame 7 and the second side frame 8 , and an upper brace 9 is set between the upper frame 6 and the first side frame 7 and the second side frame 8 . Four bottom connection...

Embodiment 2

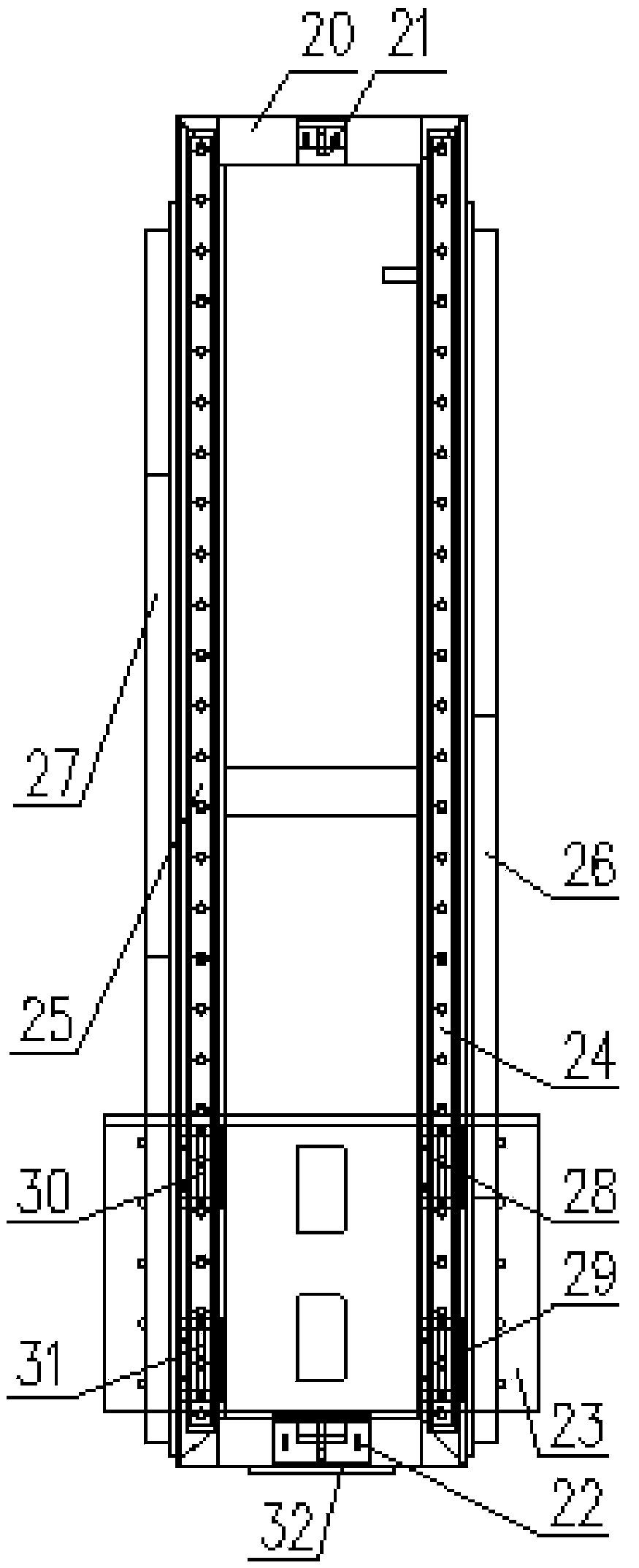

[0038] An upper anti-collision head 21 and a lower anti-collision head 22 are installed at the upper and lower ends of the pressing frame 20 of the pressing device 4 to prevent the pressing device 4 from colliding when it slides up and down.

Embodiment 3

[0040] Such as Image 6 As shown, the indenter 5 is composed of an indenter welding assembly, an indenter wrapping plate 34 and a pressing plate 36 . The pressure head cladding plate 34 is combined and connected with the pressure head welding by screws, which can prevent shredded tobacco from remaining on the pressure head 5 during the pressing down process.

[0041] As an improvement on the technical solution of Example 1, the smaller end of the indenter cladding plate 34 is connected with an indenter welding assembly, which is composed of an indenter connecting plate 33, a connecting beam 35 and a reinforcing plate 37, and the indenter is connected One end of the connecting beam 35 is connected to the bottom of the plate 33, and the other end corresponding to the connecting beam 35 is connected to the pressing plate 36. A reinforcing plate 37 is arranged between the connecting plate 33 and the pressing plate 36 and on the connecting beam 35, which strengthens the whole Inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com