Tail wheel regulating device of novel bucket elevator

A bucket elevator and adjusting device technology, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of abnormal operation, excessive dependence, overload tripping of bucket elevator, etc., so as to reduce the cleaning workload and reduce the Effect of fatigue strength and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

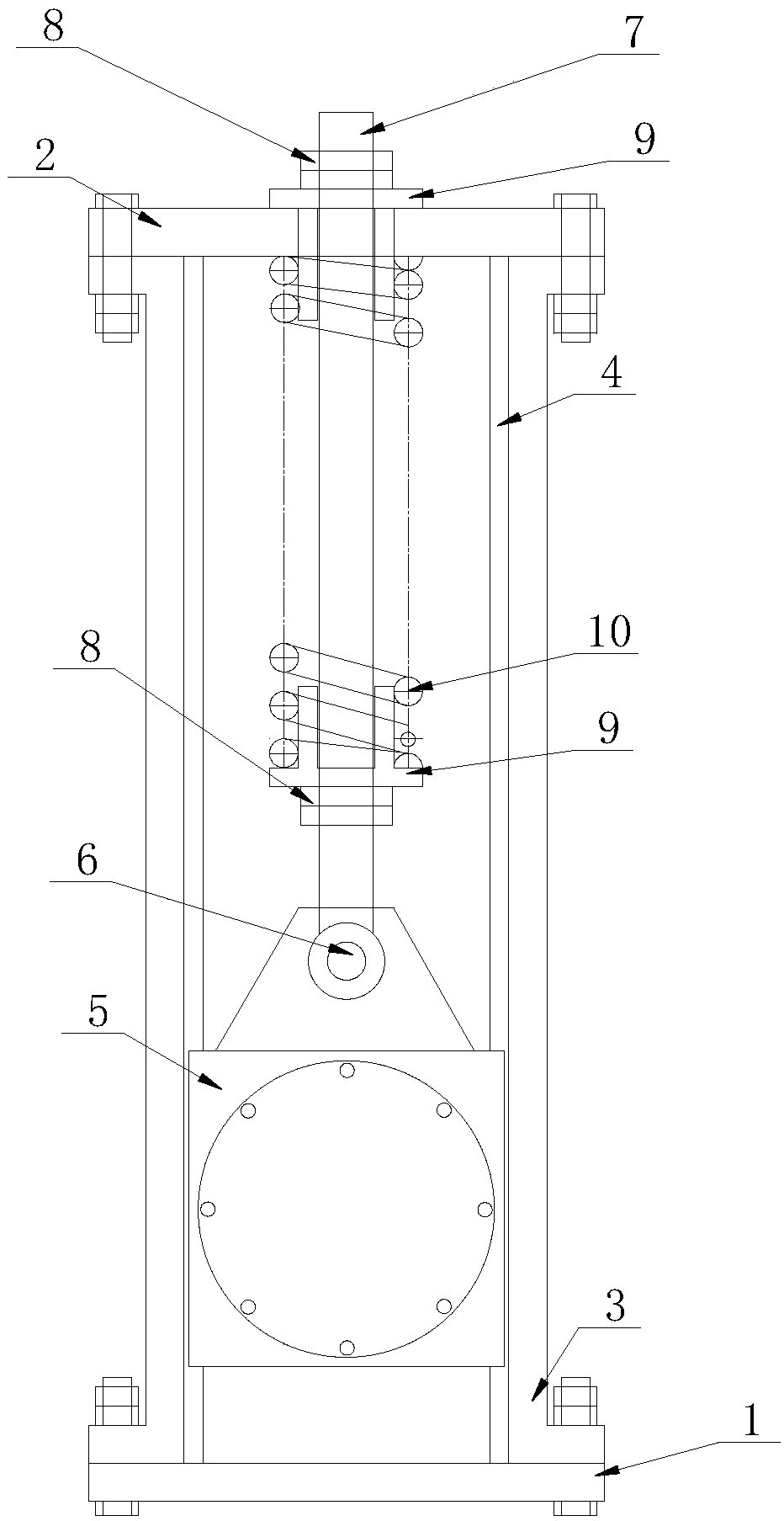

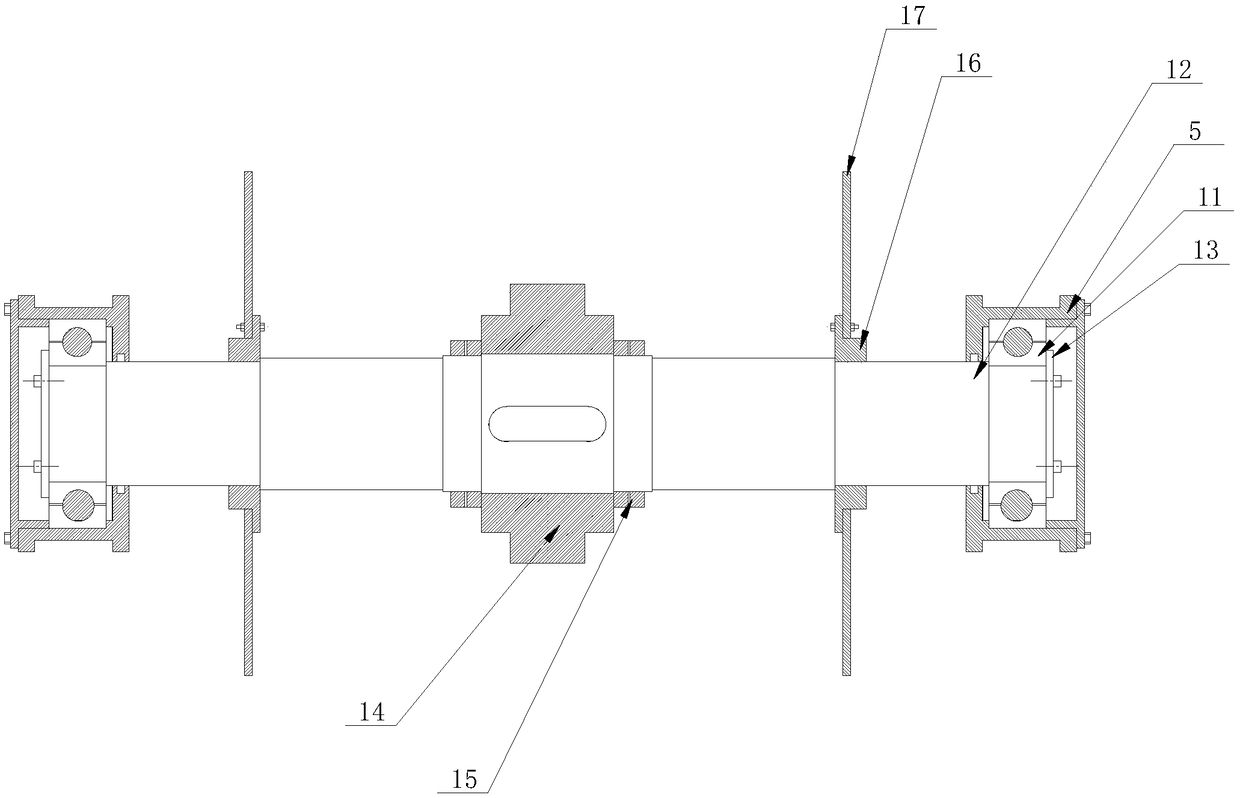

[0021] From Figure 1-2 It can be seen that the tail wheel adjusting device of a novel bucket elevator in this embodiment comprises a base 1, a pressing plate 2 and a standing plate 3, and the upper and lower ends of the standing plate 3 are respectively connected with the pressing plate 2 and the base 1, and the standing plate The upper and lower ends of 3 are detachably assembled with the pressure plate 2 and the base 1 by connecting bolts respectively, and a slider 4 is arranged between adjacent stand plates 3, and a bearing seat 5 is arranged on the inner side of the slider 4, and the bearing seat 5 and the slider 4 Sliding connection, the upper end of the bearing seat 5 is fixedly installed with a connecting pin shaft 6, the upper end of the connecting pin shaft 6 is connected with an adjusting screw 7, and the outer ring of the adjusting screw 7 is also equipped with an adjusting nut 8 and a spring washer 9 at intervals. The screw rod 7 and the adjusting nut 8 are movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com