Annealing liquid supplying interruption preventing system and method

An annealing liquid and liquid supply technology, which is applied in the field of annealing liquid supply anti-interruption system, can solve the problems of difficult pressure sensors, large economic losses, and waste products, and achieve the effect of avoiding the interruption of the annealing liquid supply process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

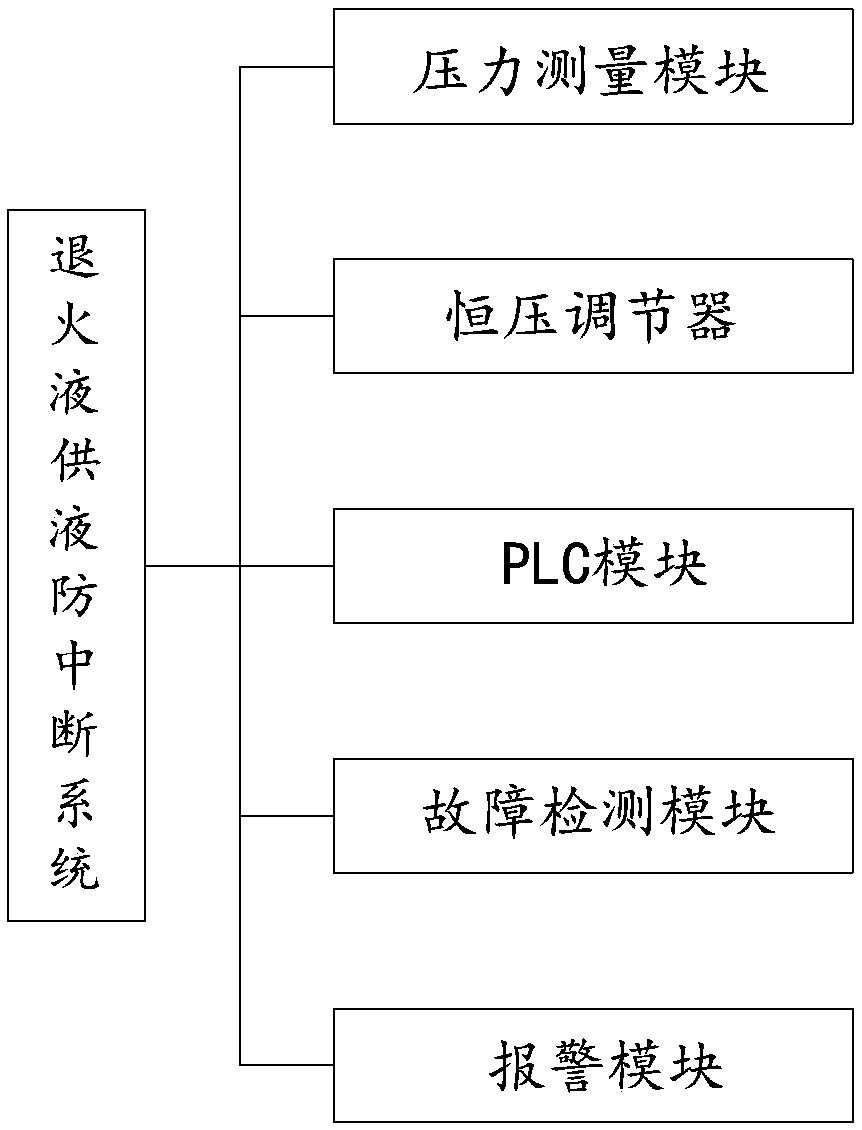

[0032] An annealing liquid supply anti-interruption system provided by a preferred embodiment of the present invention includes:

[0033] The pressure measurement module includes 4 pressure sensors for measuring the pressure at 4 points on the pipeline, and 2 pressure sensors are installed on the upper and lower sides of the pipeline. The upper and outer sides of the pipeline are fixed with fixing parts for installing the pressure sensor. After the pressure sensor installed on the upper side of the pipeline is inserted into the pipeline, the head of the pressure sensor is in contact with the inner wall of the pipeline. Both pressure sensors are installed on the top of the pipeline at the liquid inlet. outside.

[0034] The PLC module is used to obtain the minimum pressure value P among the data detected by multiple pressure sensors installed on the lower side of the pipeline min .

[0035] Constant pressure regulator, based on minimum pressure value P min and the preset pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com