A kind of smooth skin-friendly hot air water repellent cloth and its preparation process and application

A preparation process and smooth technology, applied in the fields of application, non-woven fabrics, textiles and papermaking, etc., can solve the problems of not being able to improve the overall quality of the air-repellent fabric, reducing the comfort of the air-welding fabric, and the fibers cannot be fully bonded, etc. It achieves the effect of facilitating removal and finishing, smooth hand feeling and improved skin contact comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

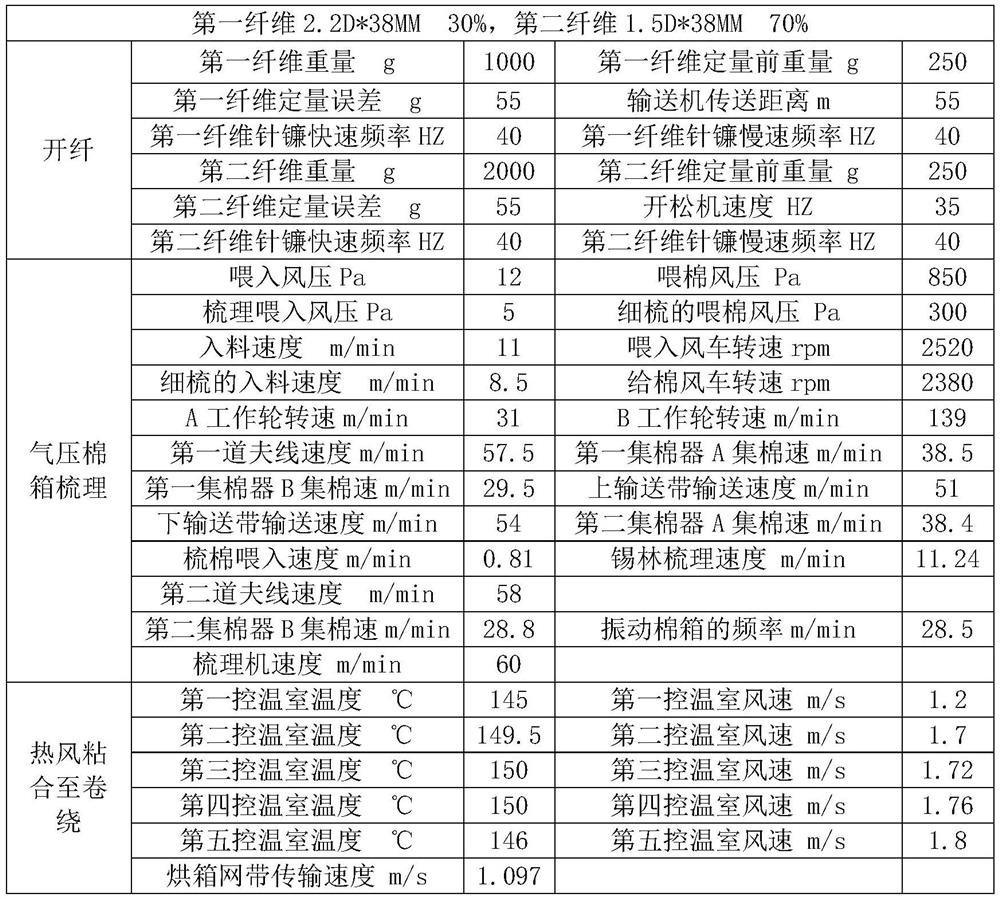

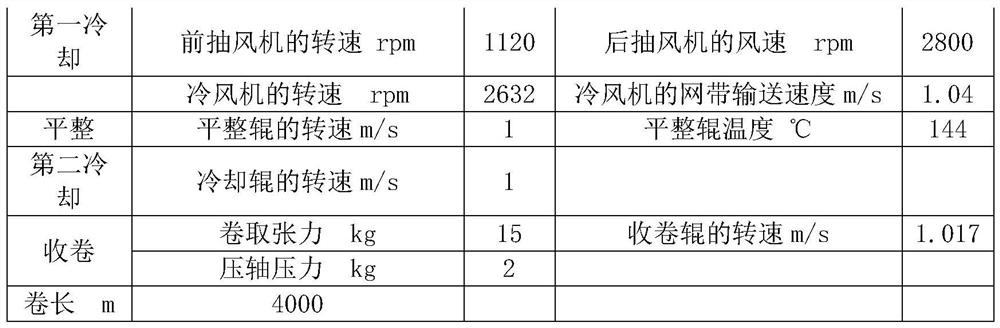

[0024] The process of producing smooth skin-friendly hot-air water-repellent fabric includes: blending the first fiber and the second fiber, finely combing, bonding, first cooling, flattening and second cooling. The specific process parameters are shown in Table 1.

[0025] Two kinds of fibers are purchased from the market, the first fiber fineness is 2.2D, the second fiber fineness is 1.5D, and the length is 38mm.

[0026] Control the quality that drops into the first fiber in the first bale opener to be 1000g, and the quality that drops into the second fiber in the second bale opener is 2000g.

[0027] Further, the following steps are carried out in sequence: blending the first fiber and the second fiber, fine carding, bonding, first cooling, smoothing and second cooling.

[0028] Further, before entering the cotton blending process, the first fiber and the second fiber are first opened, which is beneficial to the subsequent cotton blending process. In the embodiment provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com