Wire harness dyeing device and method

A dyeing device and wire harness technology, applied in the field of dyeing devices, can solve problems such as unsuitable installation of lamps, shortening of dyeing time, and difficulty in coloring, so as to achieve stable lighting light, ensure the quality of dyed threads, and ensure the lighting requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

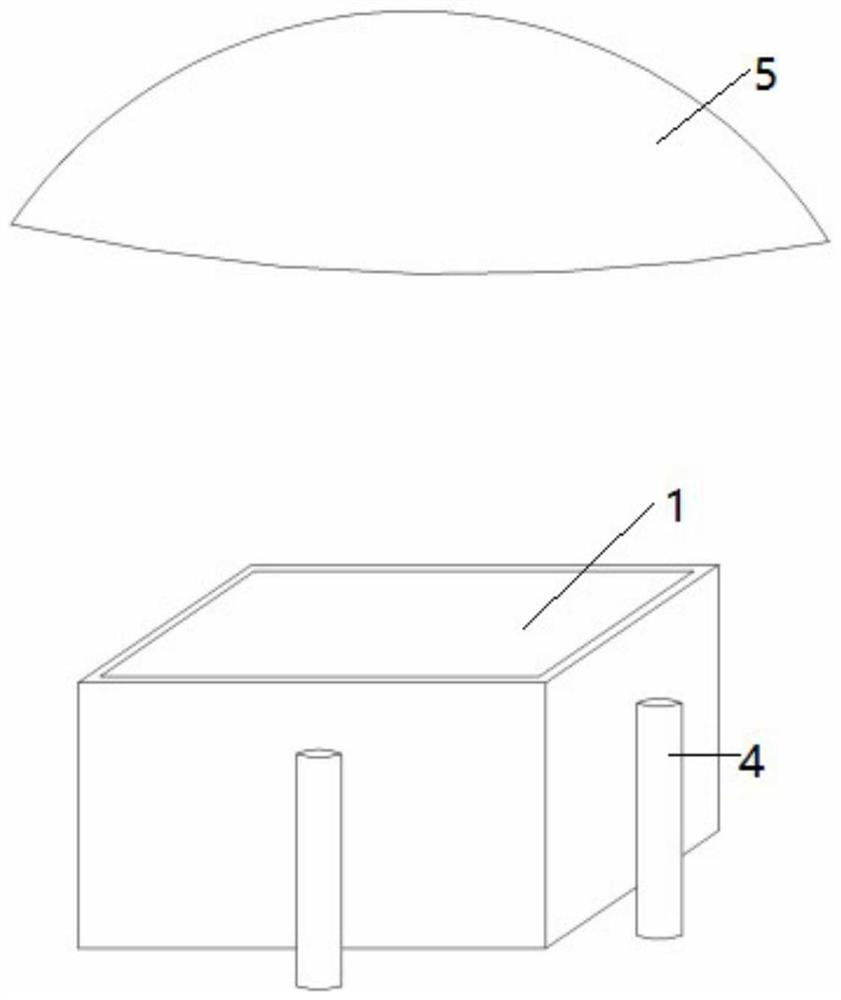

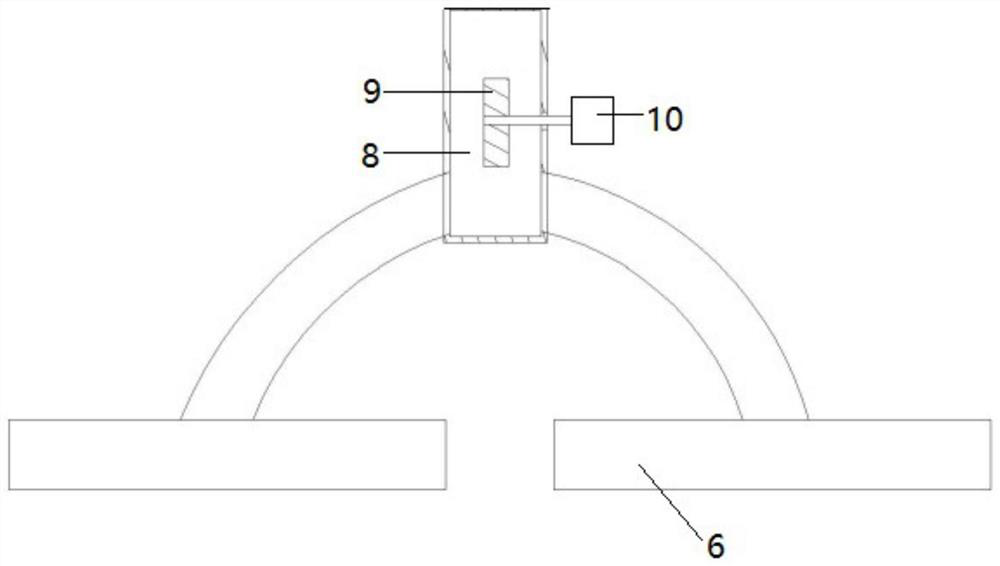

[0034] Such as figure 1 , Figure 5 The illustrated embodiment is a wire harness dyeing device, which includes a pool body 1 with an open upper end, a solution stirring device 2 installed in the pool body, a heating device 3 installed on the pool body, and four lighting fixtures located outside the pool body. Lamp 4, an upwardly arched concave mirror 5 located above the pool body; Figure 7 As shown, each illuminating lamp is arranged in an annular lampshade 201 surrounding the pool body, and a vacuum pump 202 is provided on the annular lampshade. The annular lampshade is connected to the ground through a lifting device 203, and also includes two suction covers 6 as shown in the figure. , each suction hood is provided with a suction pump, and each suction hood is connected with the exhaust pipe 8, and the exhaust pipe is provided with an impeller 9, and the rotating shaft of the impeller is connected with the worm gear structure 10, and the turbine of the worm gear structure ...

Embodiment 2

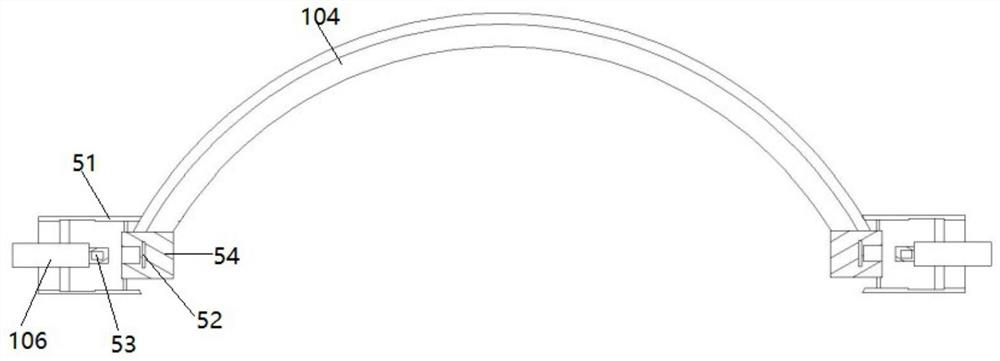

[0050] Embodiment 2 includes all structure and method parts of embodiment 1, such as image 3 As shown, the worm gear of embodiment 2 is meshed with the gear, and the rotating shaft of the gear is connected with another flexible shaft 106; the two ends of the arc brush are connected with the concave mirror through the fixed housing 51, and each fixed housing is provided with an arc brush. The fixed block 52 that is fixedly connected, the fixed block is rotatably connected with the fixed shell, and each flexible shaft is all rotatably connected with the corresponding fixed shell, and a permanent magnet 53 is arranged in each flexible shaft end, and a permanent magnet 53 is arranged in each fixed block. There are electromagnets 54, both of which are electrically connected to the controller.

[0051] The controller alternately controls the two electromagnets to be energized, so that the two flexible shafts are alternately connected and disconnected with the arc-shaped brush, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com