Prefabricated hollow pipe pile deviation correcting method

A hollow tube, prefabricated technology, applied in construction, infrastructure engineering, etc., to achieve the effect of saving construction costs and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

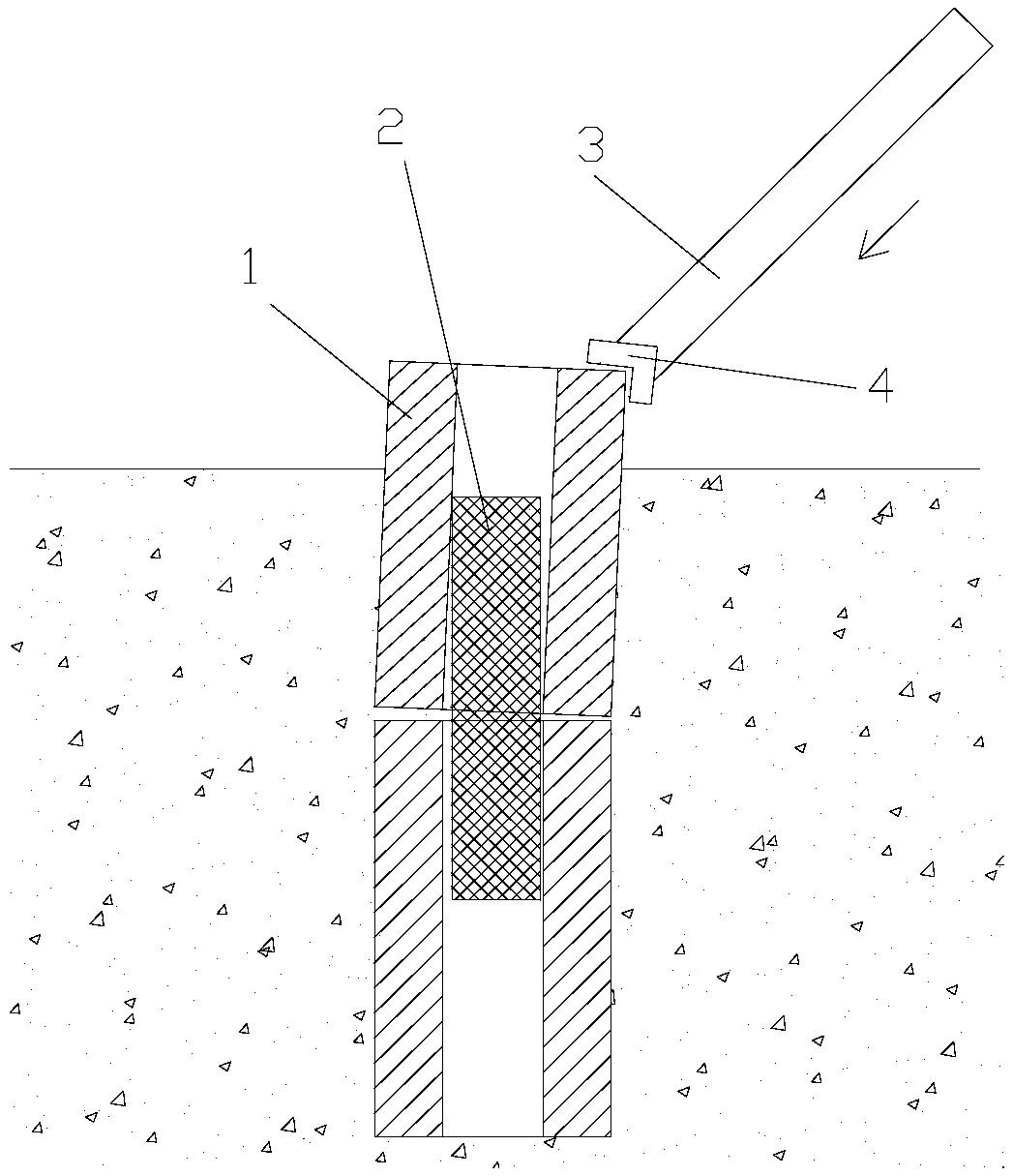

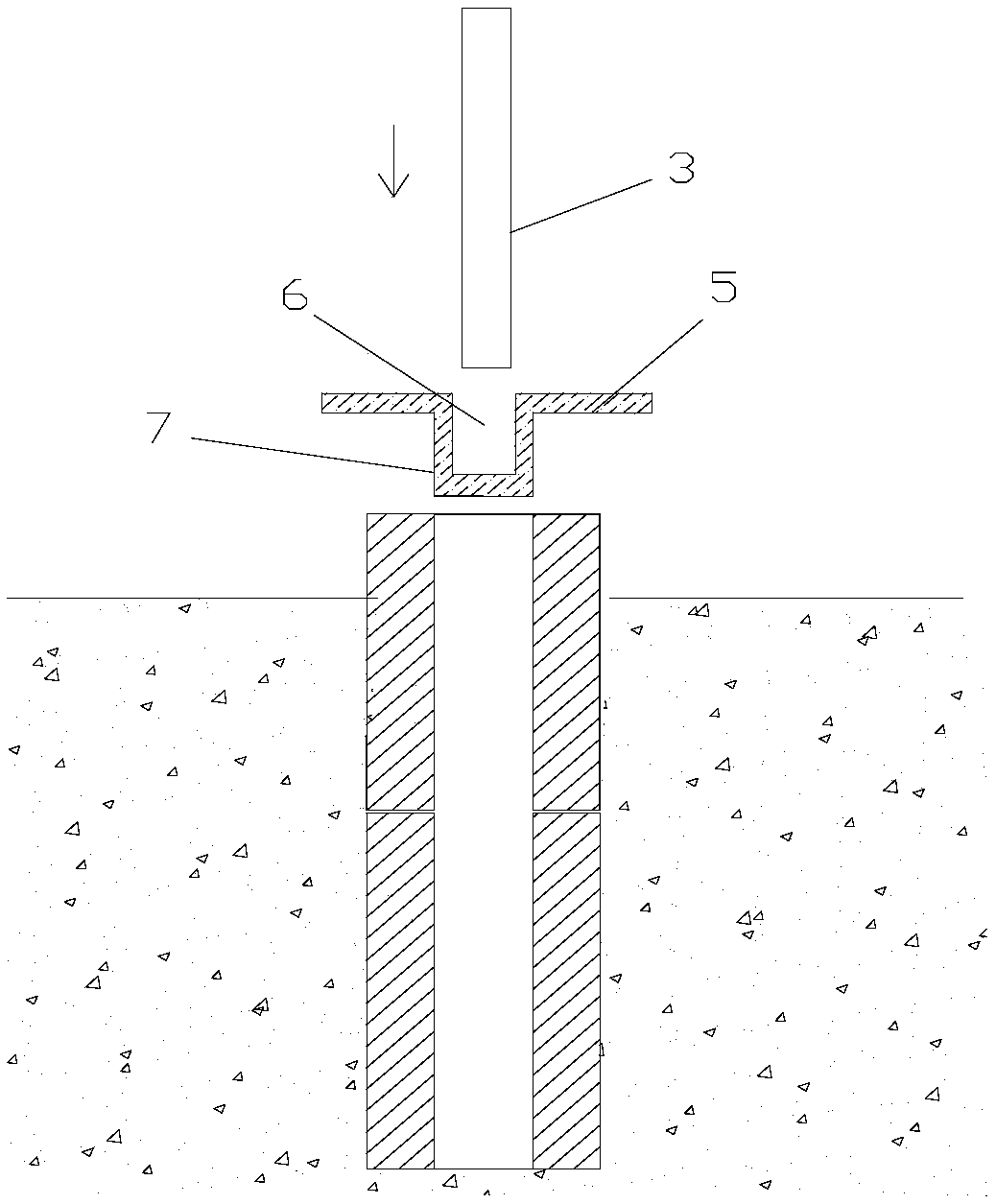

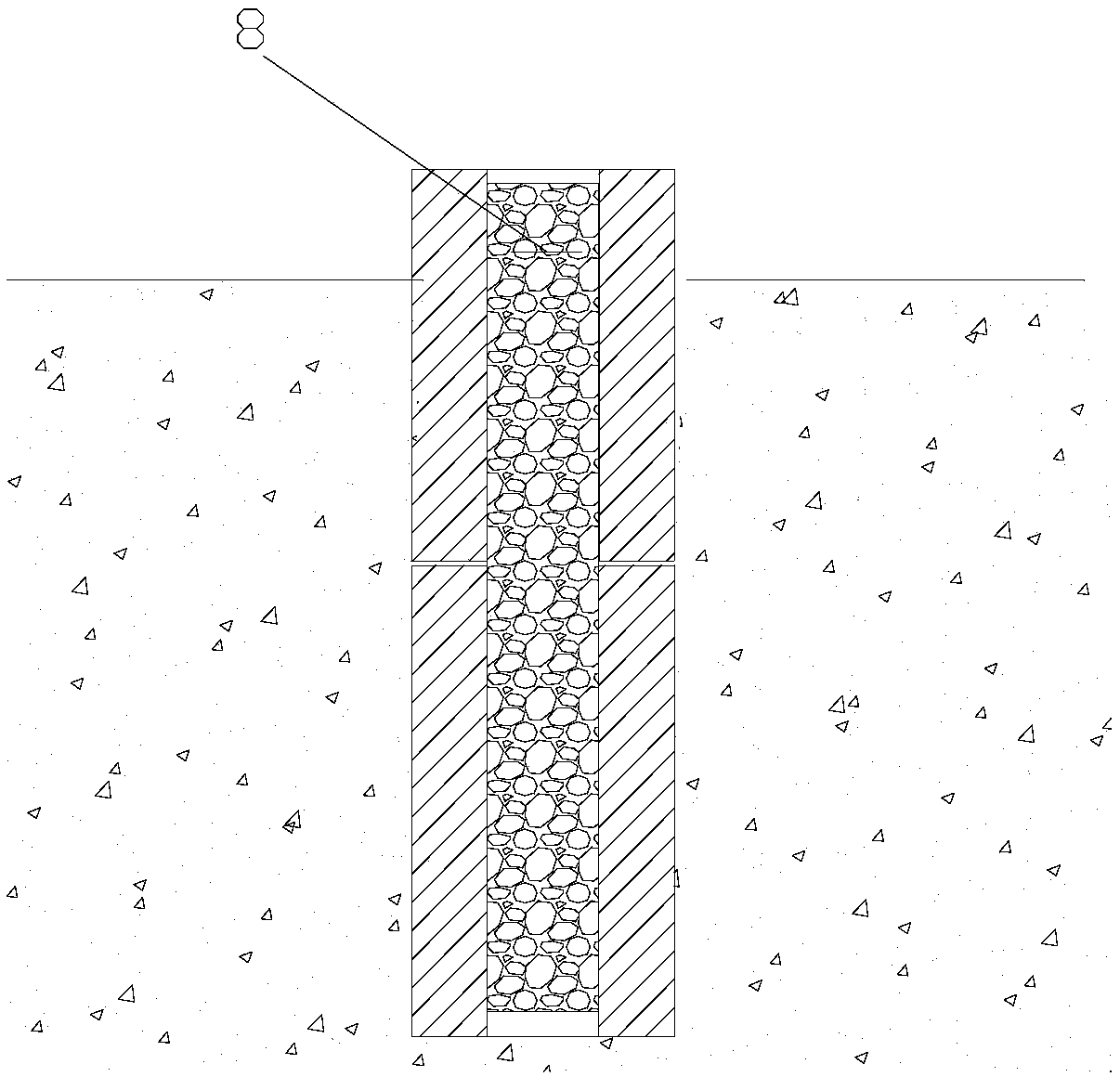

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1-3 As shown, a prefabricated hollow pipe pile rectification method, the general hollow pipe pile has two sections, this device is aimed at correcting the deviation of two prefabricated hollow pipe piles, which specifically includes the following steps: Step 1, in two adjacent hollow pipe piles A metal pin 2 is inserted between the piles 1 to connect the two hollow pipe piles into a whole; this step is a necessary step, if a metal pin is not inserted in the subsequent steps, the upper hollow pipe pile will move as a whole , completely break away from the hollow pipe pile of the bottom, for this reason, through testing, design a metal pin, the outer diameter of metal pin is slightly smaller than the inner diameter of hollow pipe pile, has certain weight, and the top of metal pin is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com