Infill wall connecting assembly in fabricated steel structure system

A technology for connecting components and steel structures, which is applied to building components, walls, and building structures. It can solve problems such as time-consuming and labor-intensive installation and removal of brackets, difficult positioning of wall panels, and easy flashing of wall panels. Save construction time, strong concealment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

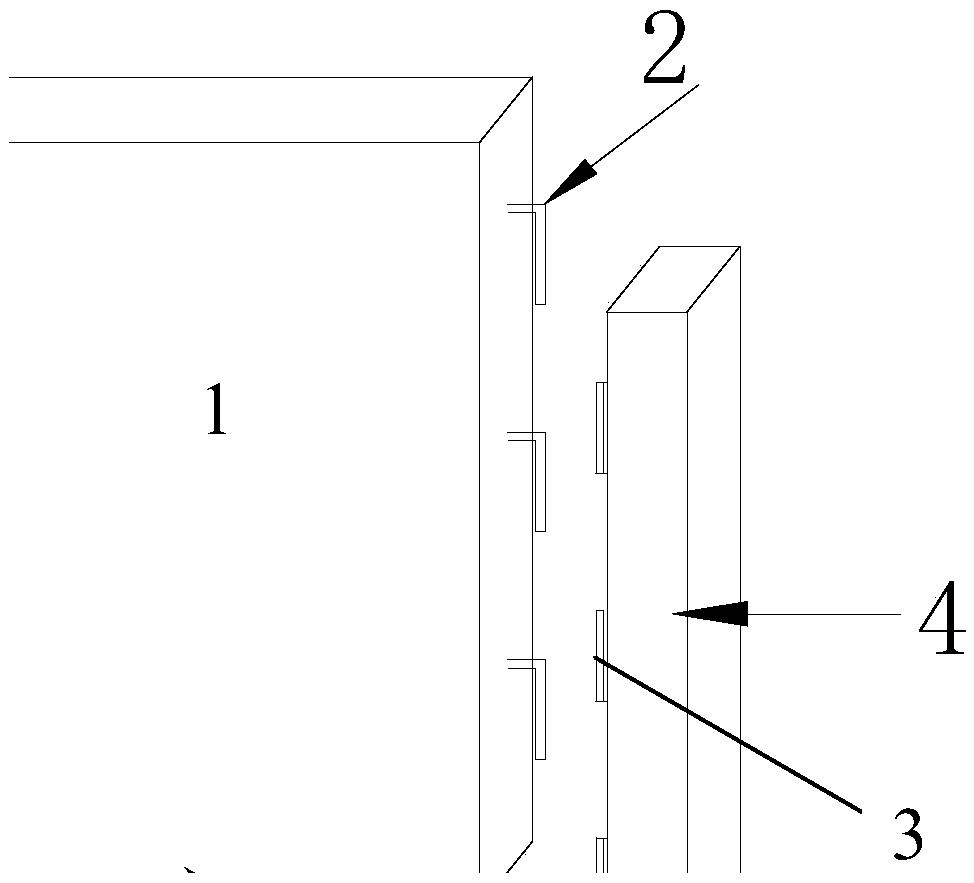

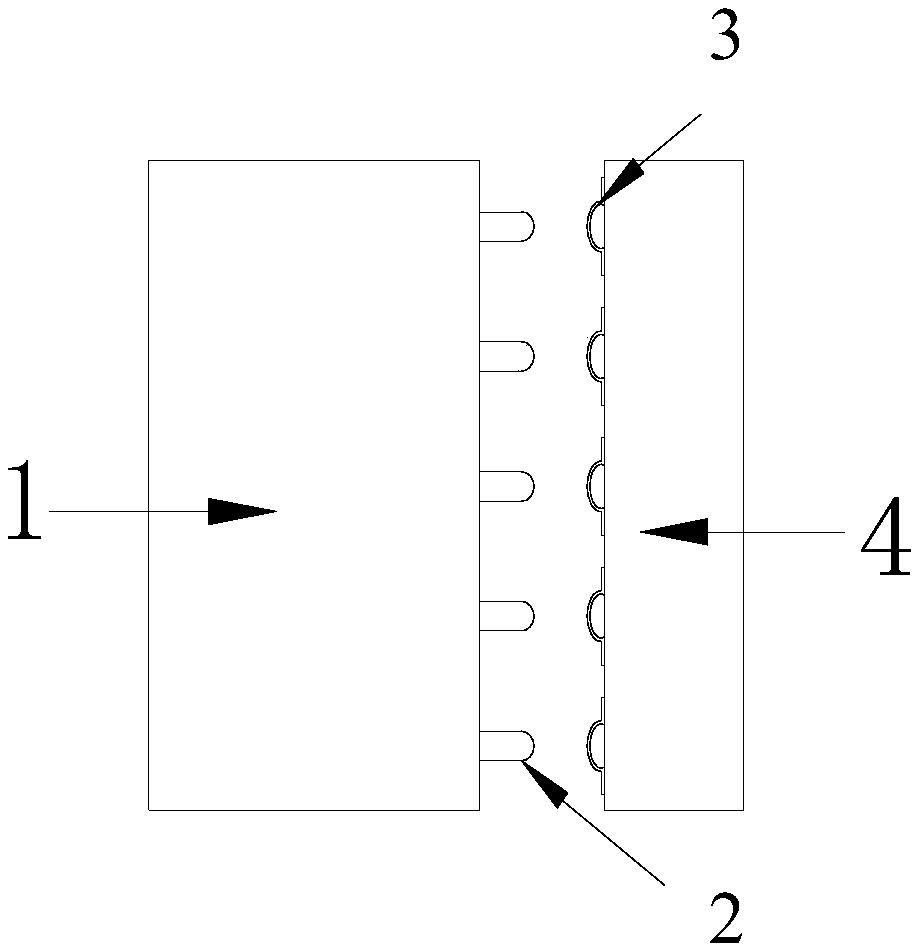

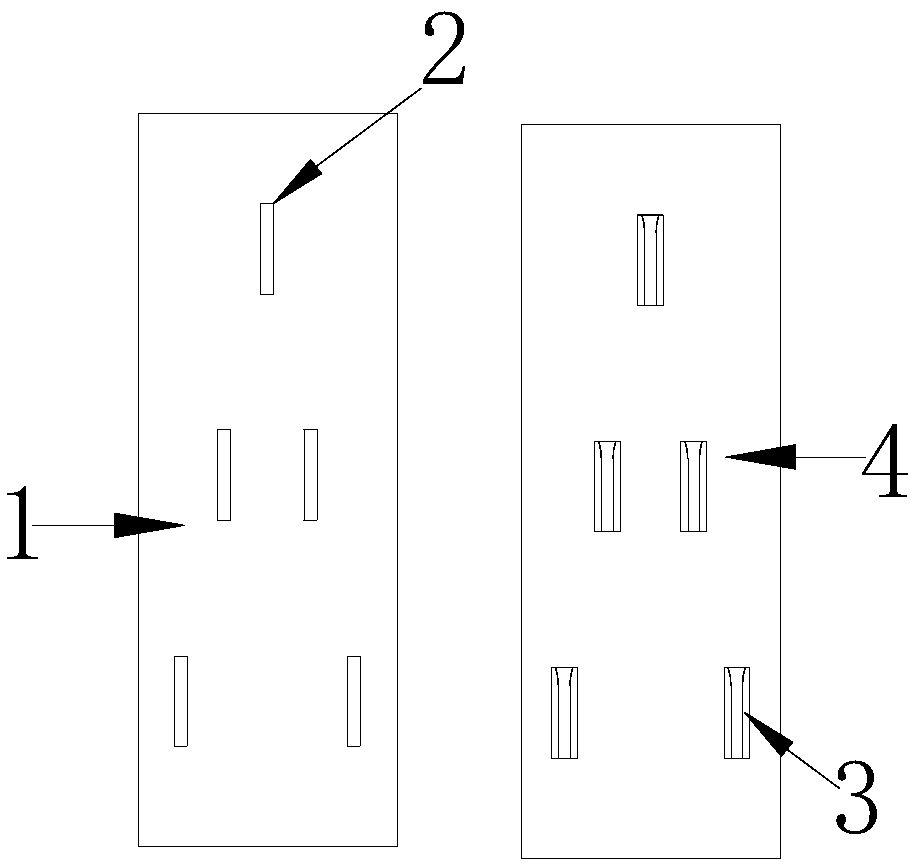

[0019] Such as Figure 1 to Figure 6 As shown, in the assembled steel structure system provided by the present invention, the embedded wall connection assembly is arranged between the embedded wall 1 and the steel pipe column 4, including bent steel bars 2, steel sleeve 3 and frictional energy dissipation layer 7 ; Wherein, the inner ends of a plurality of bent steel bars 2 are pre-embedded in the interior of the embedded wall 1 from top to bottom in a state of horizontal setting, and the outer ends are bent downwards after protruding from the outer end surface of the embedded wall 1 A folded 7-shaped structure; on the outer end surface of the steel pipe column 4 adjacent to the embedded wall 1, a plurality of steel sleeves 3 corresponding to the positions of the above-mentioned plurality of bent steel bars 2 are fixed from top to bottom; each The outer end of the bent ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com