Engine pull rod type variable valve device

A tie rod type, engine technology, applied in the direction of engine components, machines/engines, valve devices, etc., to achieve high-speed efficiency, increase service life, and continuous linear torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] specific implementation plan

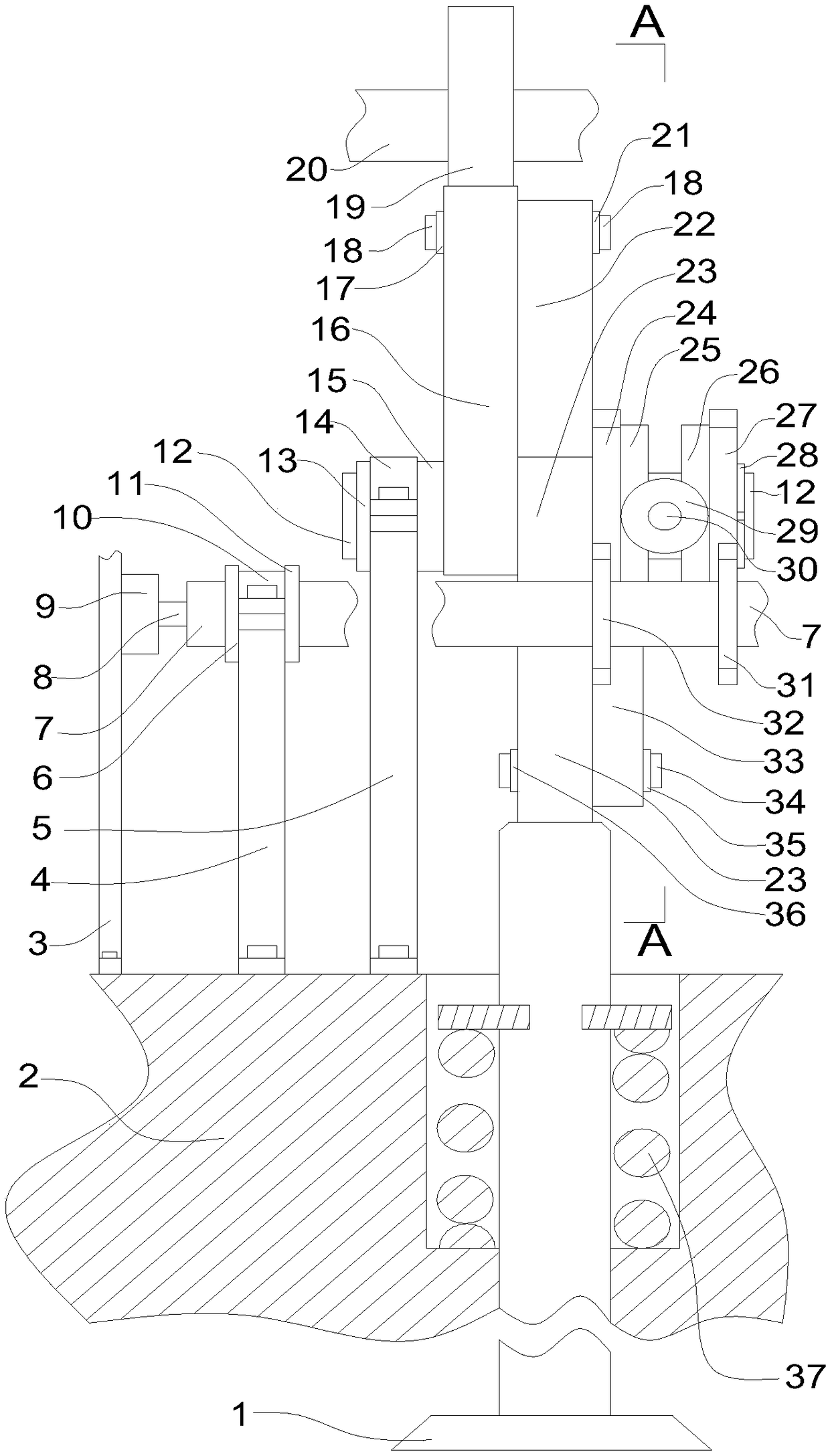

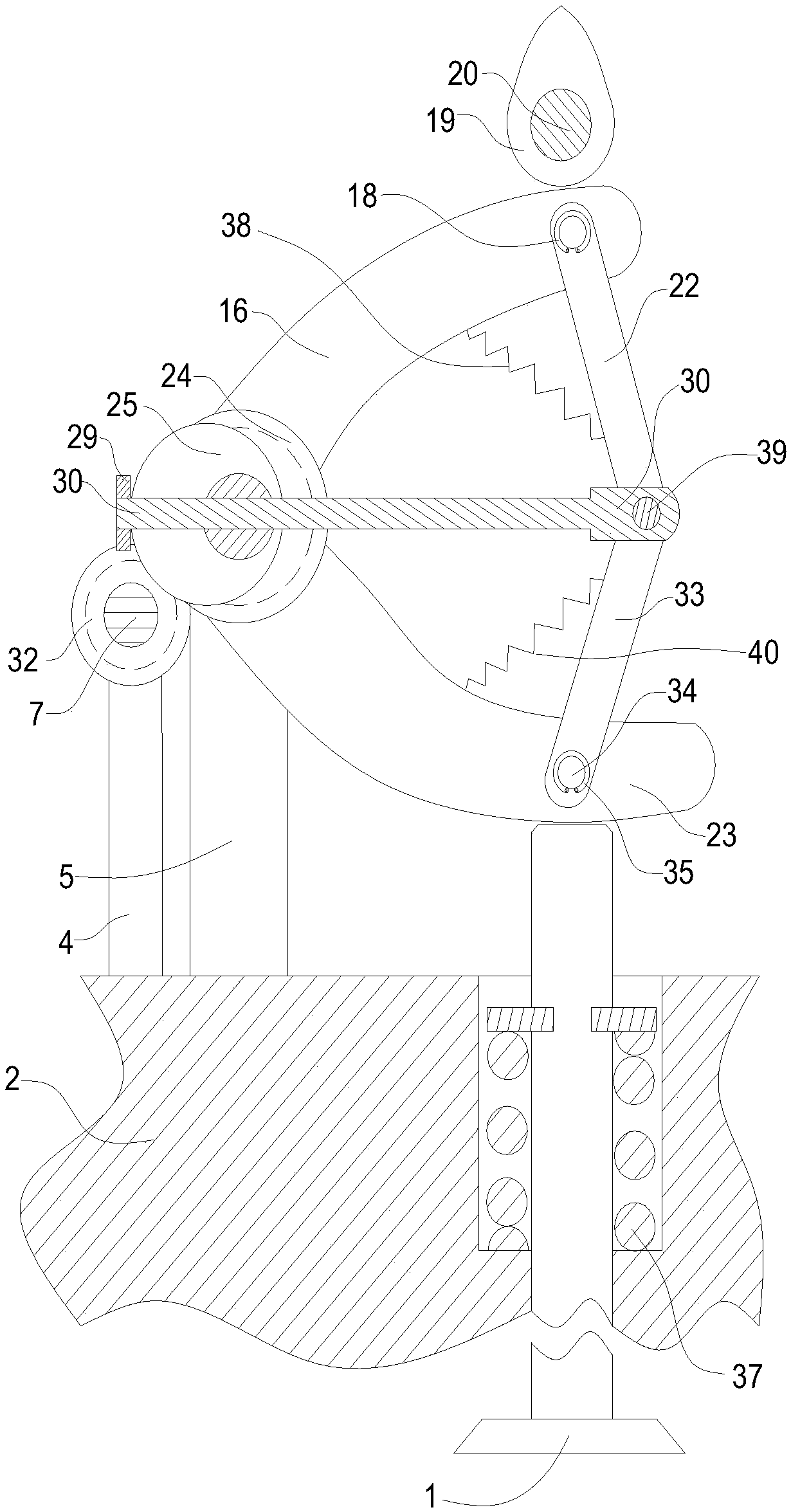

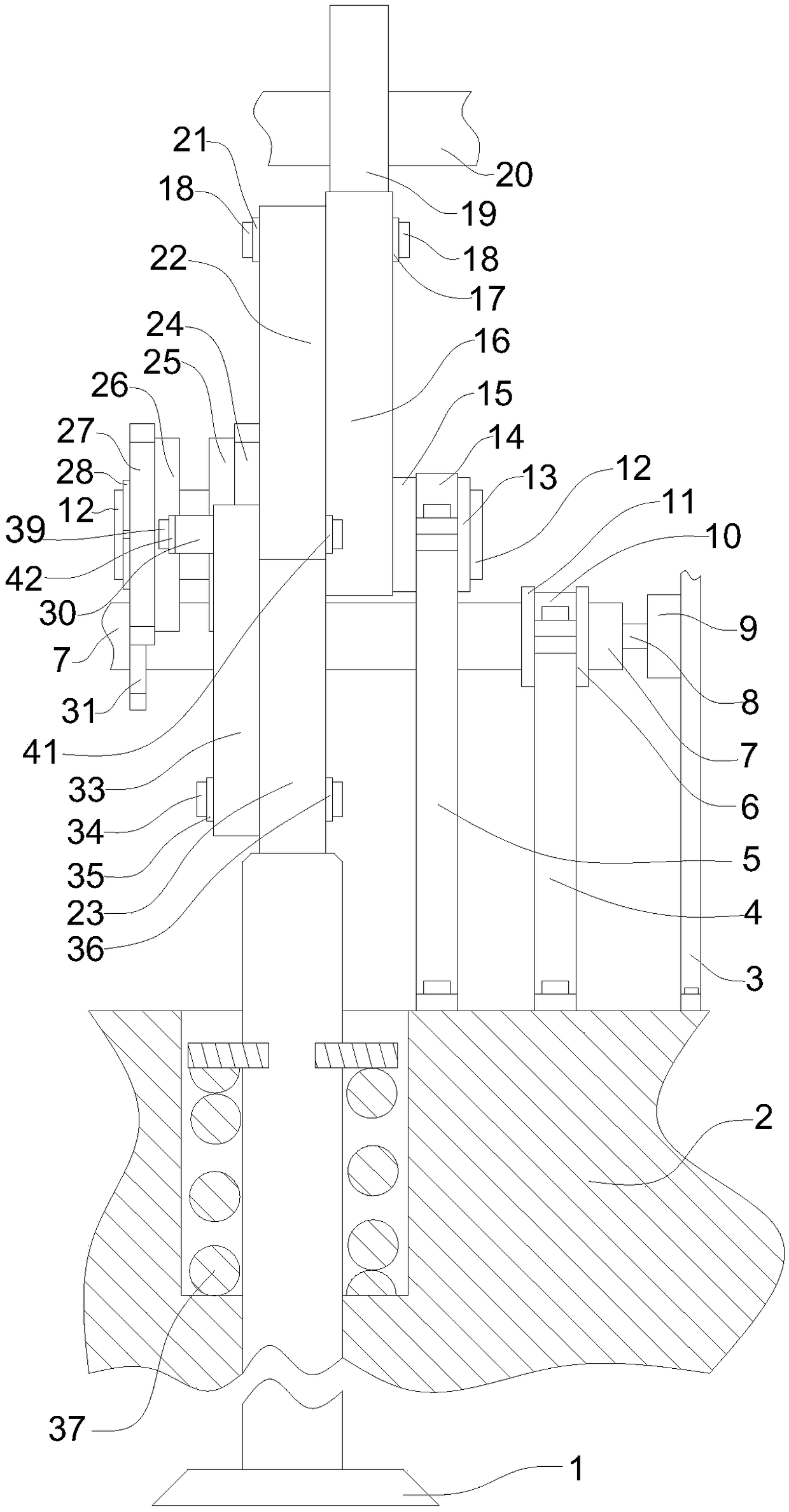

[0046] The present invention is described in detail below in conjunction with accompanying drawing:

[0047] refer to Figure 1-3 , the engine rod-type variable valve device of the present invention includes the following structures: valve 1, cylinder head 2, motor mounting frame 3, control shaft bracket 4, camshaft bracket 5, limit ring platform a6, control shaft 7, motor Shaft 8, motor 9, upper cover plate a10, limit ring platform b11, rocker arm shaft 12, limit ring platform c13, upper cover plate b14, limit ring platform d15, rocker arm a16, snap ring a17, pin shaft a18 , cam 19, camshaft 20, snap ring b21, push rod a22, rocker arm b23, gear a24, eccentric ring block a25, eccentric ring block b26, gear b27, snap ring c28, ring block 29, pull rod 30, gear c31 , Gear d32, push rod b33, pin b34, snap ring d35, snap ring e36, valve spring 37, push rod return spring a38, pin shaft c39, push rod return spring b40, snap ring f41, snap ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com