Engine rocker type variable valve device

A rocker arm type, engine technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of electro-hydraulic variable valve timing mechanism response lag, fast seating speed, large impact force, etc., to achieve responsiveness Sensitive, lightened mass, responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

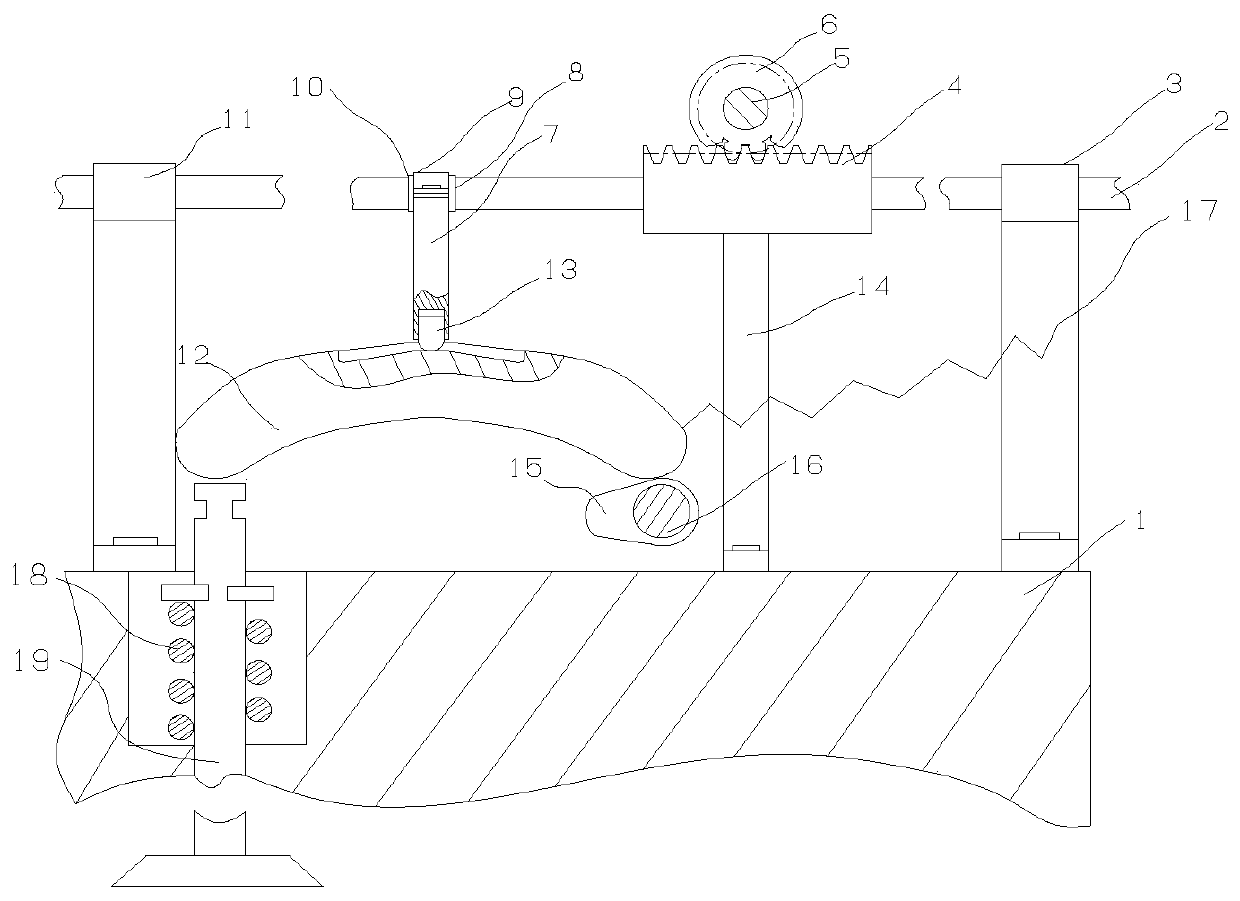

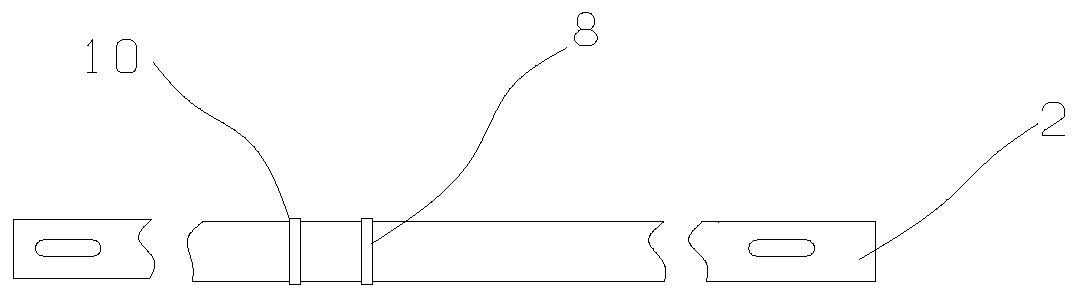

[0031] refer to figure 1 , figure 2 The engine rocker arm type variable valve device of the present invention comprises the following structures: cylinder head 1, rack shaft 2, rack shaft bracket a3, rack 4, gear shaft 5, gear 6, connecting rod 7, limit ring Platform a8, upper cover plate 9, limit ring platform b10, rack shaft support b11, rocking arm 12, slide block 13, motor support 14, cam 15, camshaft 16, thrust spring 17, valve spring 18, valve 19.

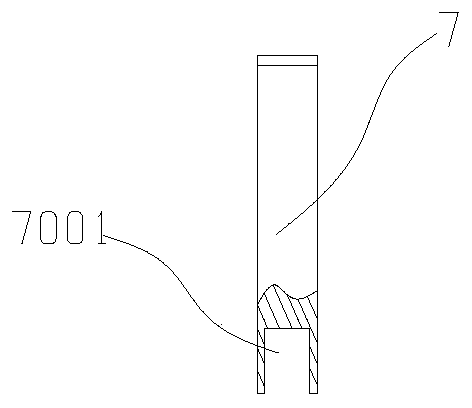

[0032] refer to image 3 , Figure 4 , Figure 6 , The engine rocker-type variable valve device of the present invention includes a connecting rod groove 7001 , a rocker groove 1201 , and a rack hole 4001 .

[0033] refer to figure 1 , image 3 , Figure 4 :

[0034] The rack shaft support a3, the rack shaft support b11 and the motor support 14 are all fixed on the cylinder head 1 with two bolts; the motor is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com