Anti-large overload combined distortion measuring rake on intake passage

A technology of air inlet and measurement rake, which is applied in the field of anti-large overload air inlet combination distortion measurement rake, which can solve the problems of unsuitable measurement, etc., and achieve the effect of simple appearance, strong anti-overload ability, and small airflow interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In conjunction with the accompanying drawings, the combined distortion measurement rake of the anti-large overload inlet port of the present invention is described as follows:

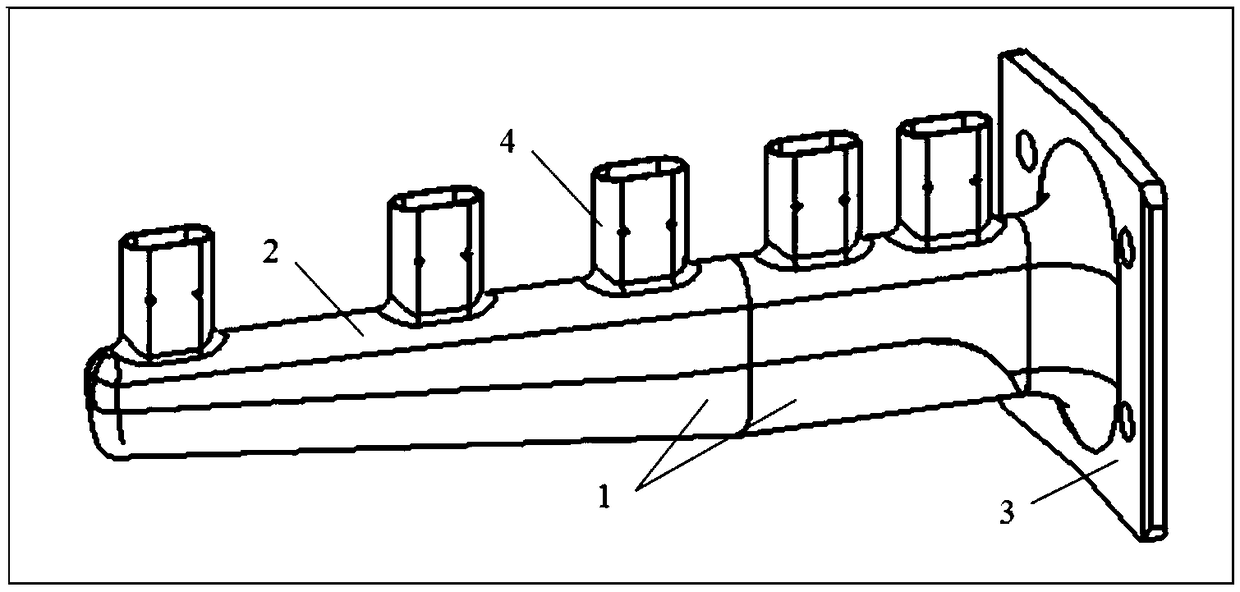

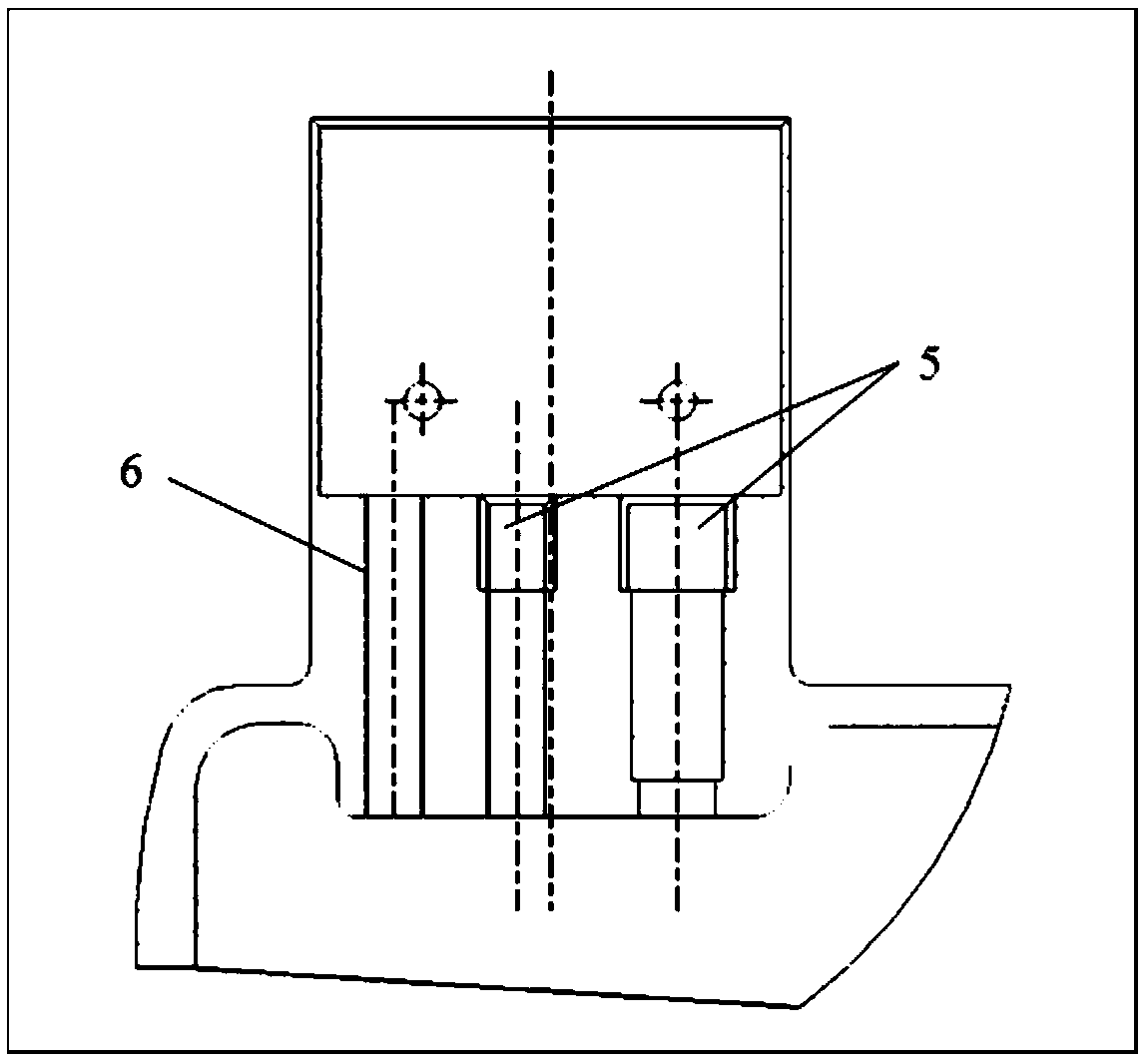

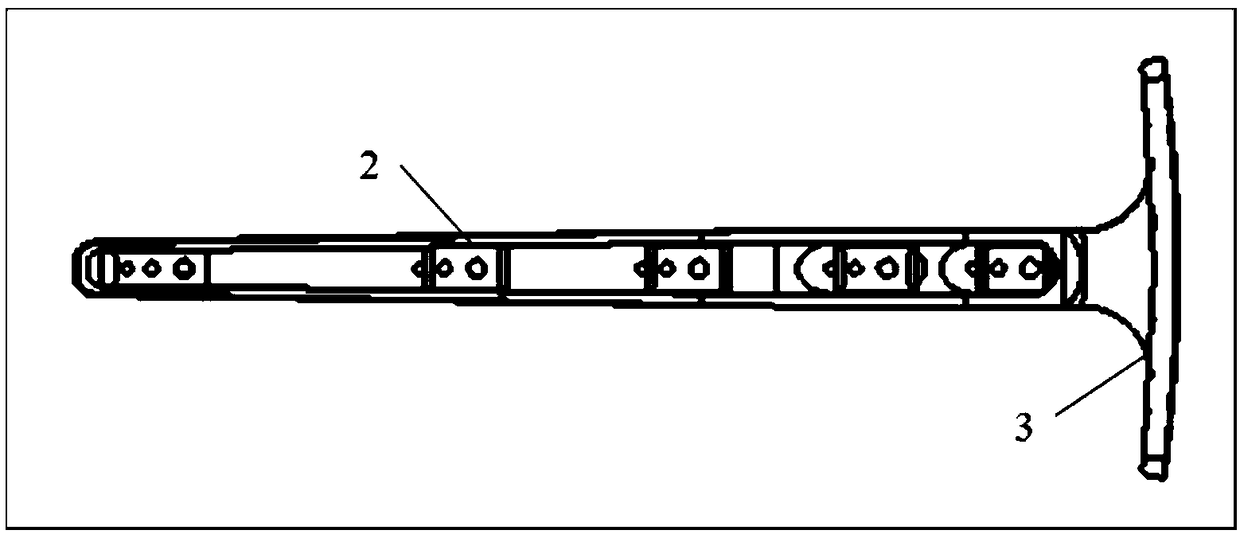

[0019] The three-dimensional schematic diagram of the combined distortion measuring rake of the anti-large overload inlet port of the present invention is attached figure 1 As shown, it consists of a steel frame and rubber material 1; the steel frame is hollow inside, and consists of a rake arm 2, a mounting base 3 and a measuring point outer casing 4, and the raking arm (2), the mounting base 3 and the measuring point The outer casing 4 is integrally processed and formed; the cross-section of the rake arm 2 is a U-shaped structure, and the outer casing 4 for measuring points for installing sensors inside is distributed along the radial direction of the rake arm (2); the base 3 is arc-shaped, There are bolt holes connected to the installation wall, and there is a hole in the middle that communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com