Control method and system for parameters self-tuning of tobacco shred production process

A technology of process parameter and self-healing control, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve the problem of abnormal parameter alarm, difficult adjustment of abnormal parameters, and no reliable evaluation method for the influence of downstream process parameters, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

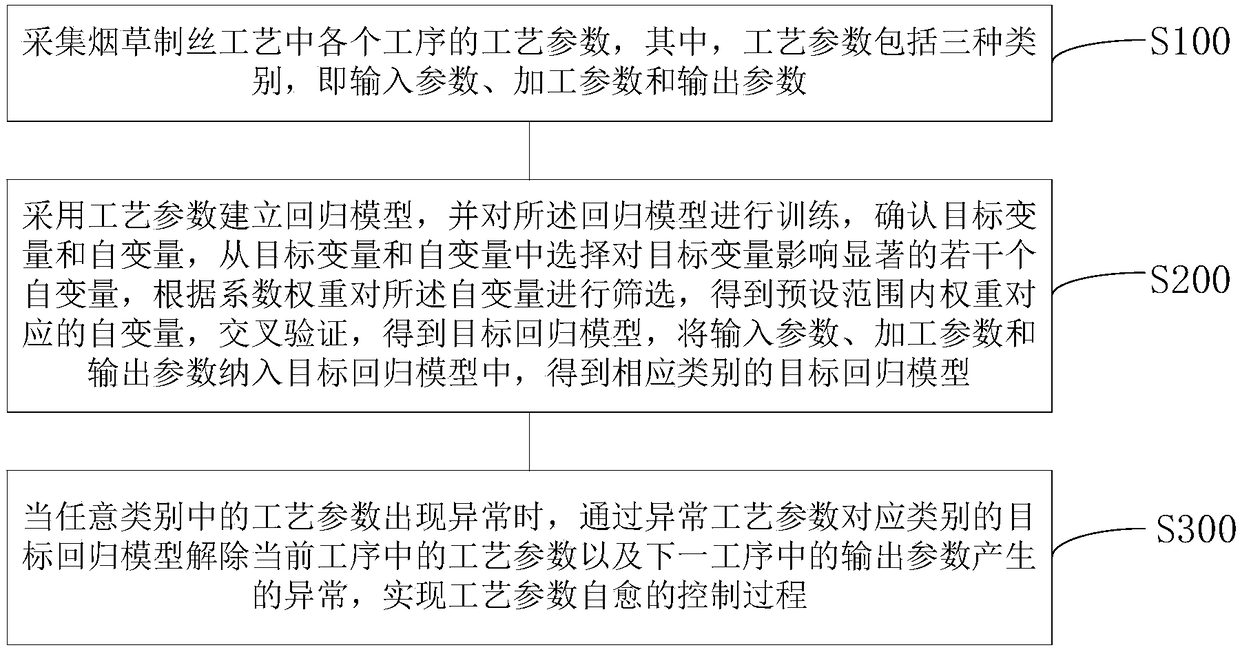

Method used

Image

Examples

Embodiment 2

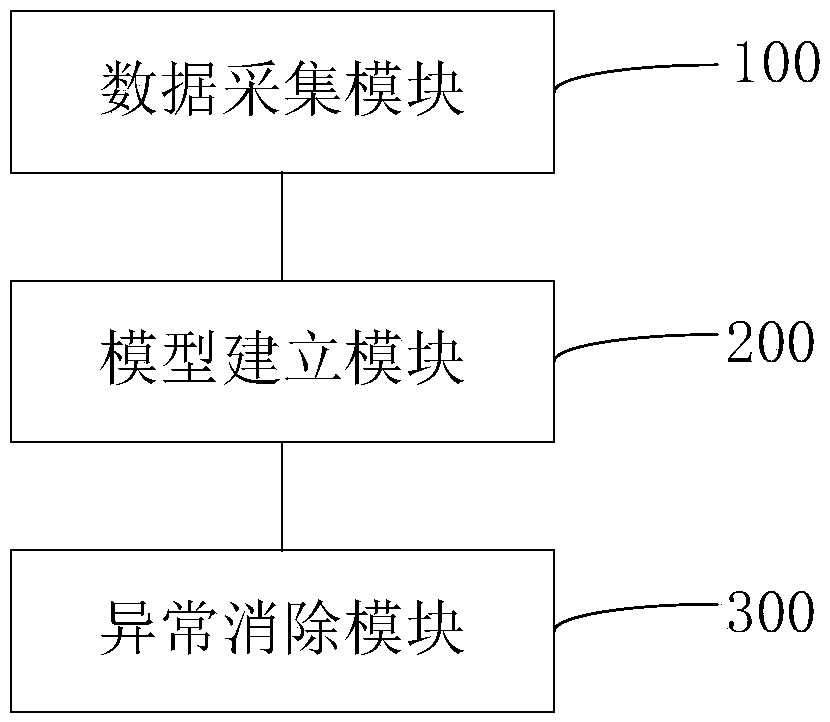

[0098] A tobacco shredded process parameter self-healing control system, as shown in the figure, includes a data acquisition module 100, a model building module 200 and an abnormal elimination module 300;

[0099] The data collection module 100 is used to collect process parameters of each process in the tobacco shredded process, wherein the process parameters include three categories, namely input parameters, processing parameters and output parameters;

[0100] The model building module 200 is used to establish a regression model using process parameters, and train the regression model, confirm the target variable and independent variables, and select several independent variables that have a significant impact on the target variable from the target variables and independent variables , filter the independent variable according to the coefficient weight, obtain the independent variable corresponding to the weight within the preset range, cross-validate, obtain the target regr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com