Full-automatic assembly production system of microswitch and sorting and discharging device

A sorting and unloading device, micro switch technology, applied in the direction of electrical switches, sorting, electrical components, etc., to achieve the effect of easy packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

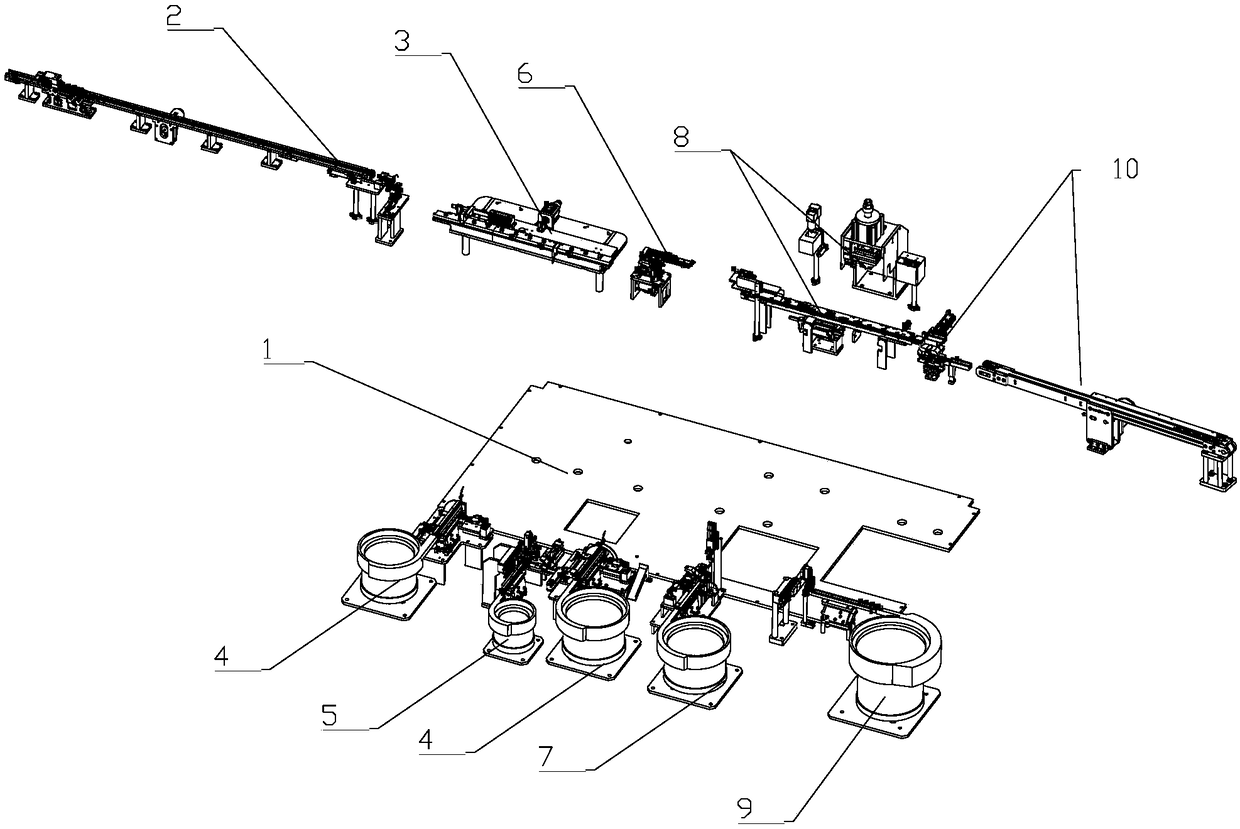

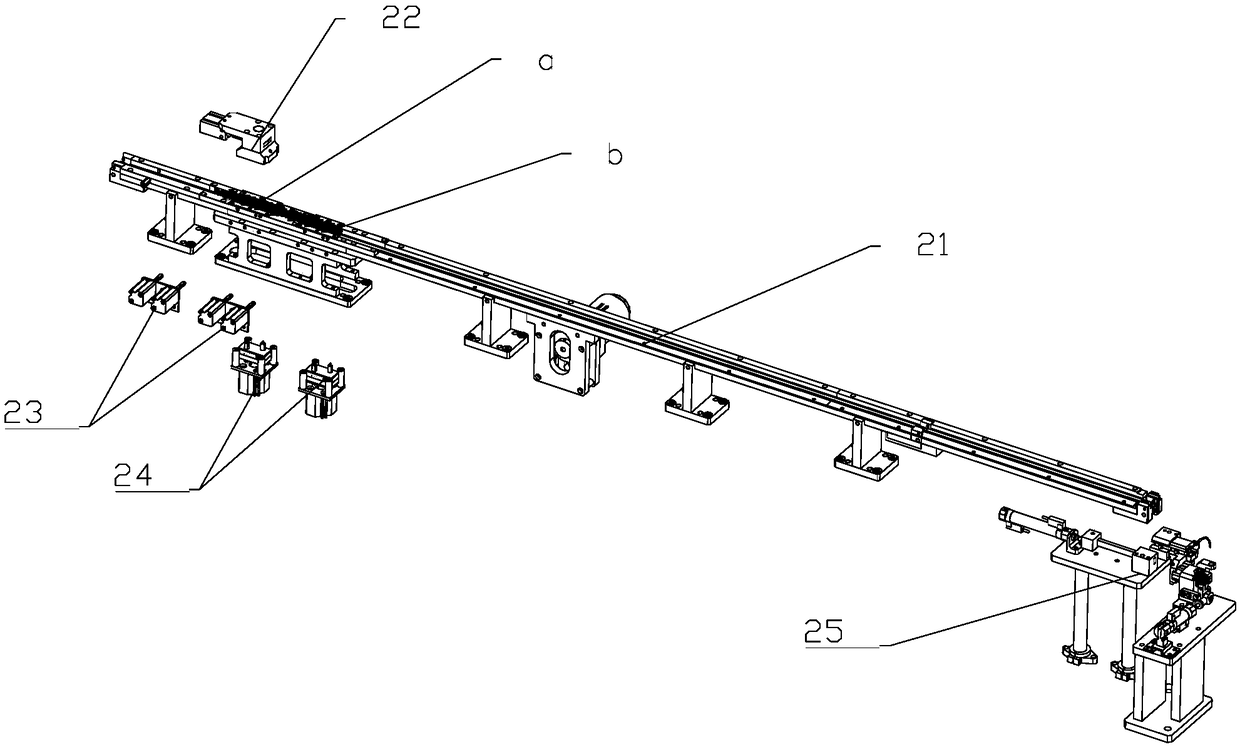

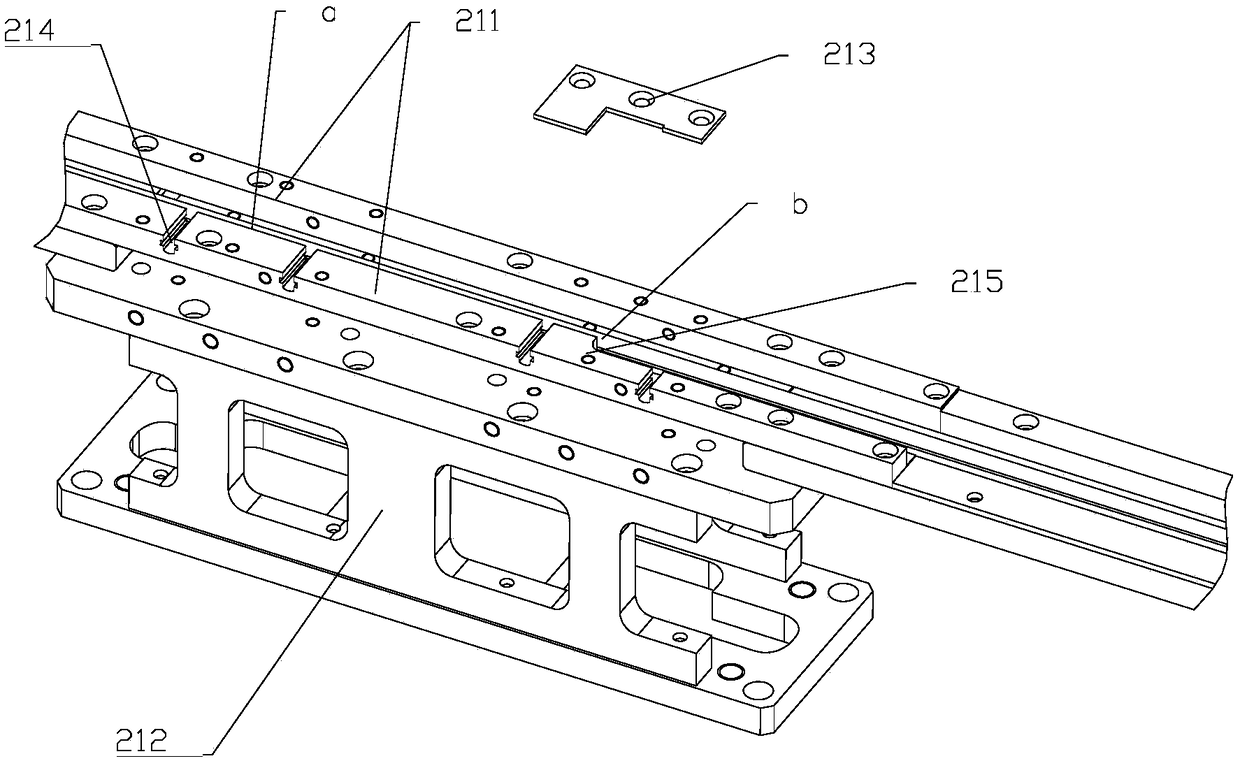

[0048] Such as figure 1 As shown, the described micro switch production equipment includes a frame 1 and a feed conveying line device 2 installed thereon, an assembly conveying line device 3, a terminal sorting and feeding device 4, a pressing and sorting and feeding Device 5, transition handling device 6, shrapnel sorting and feeding device 7, post-assembly processing conveyor line device 8, rear shell sorting and feeding device 9, and sorting and unloading device 10; along the material processing direction, the feeding conveyor line device 2. The assembly conveyor line device 3, the transition handling device 6, the post-assembly processing conveyor line device 8 and the sorting and unloading device 10 are arranged in sequence; the feeding conveyor line device 2 is used to transport the pre-assembled micro switch front shell into the material; the assembly conveyor line device 3 is connected with the feed conveyor line device 2, and is used to push the workpiece into the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com