Quick-open type filter press

A filter press, quick-opening technology, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve problems such as reducing the operating efficiency of the filter press and slow opening of the filter press plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The patent of the present invention selects 30 vertical filter press plates and 30 sets of filter cloths to provide the following specific examples.

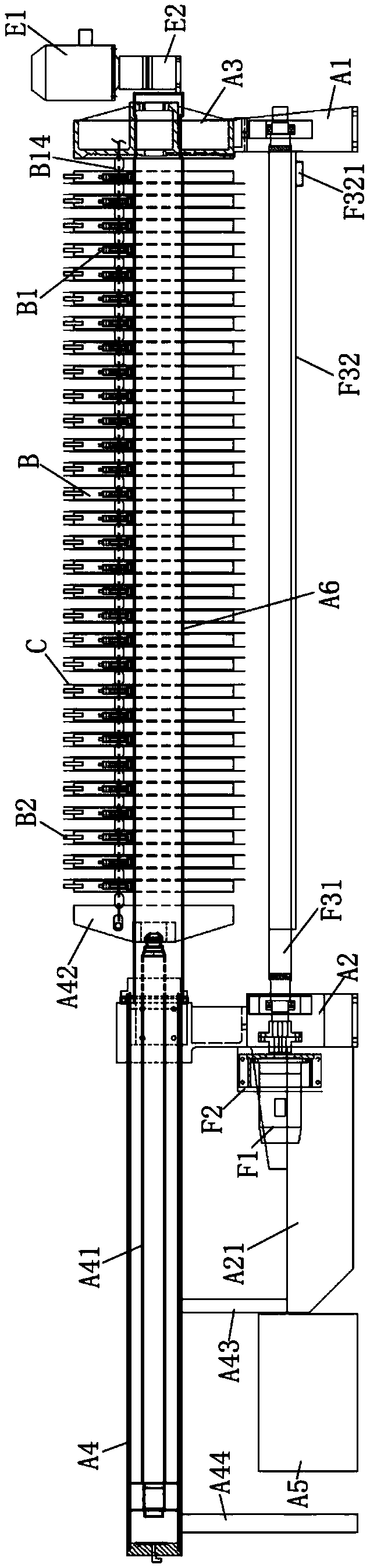

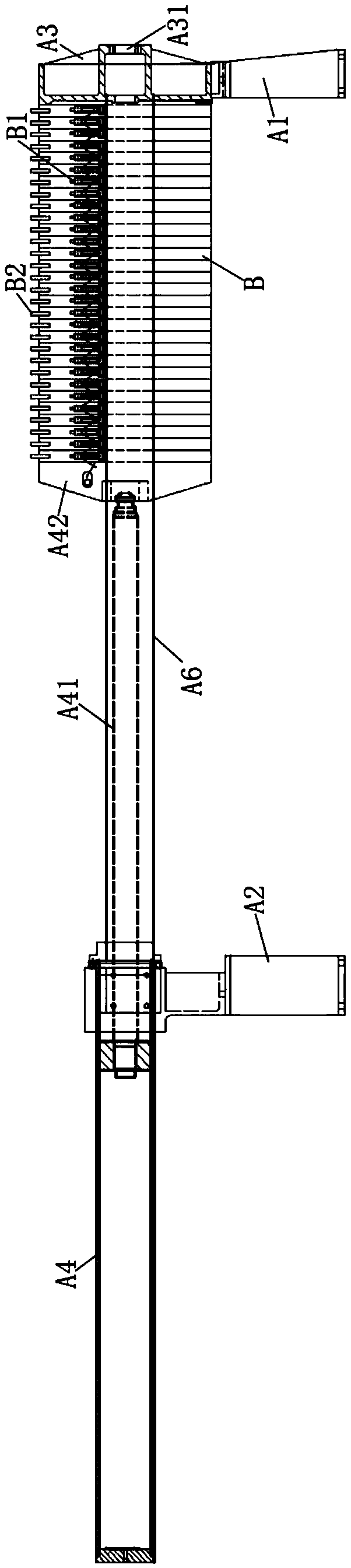

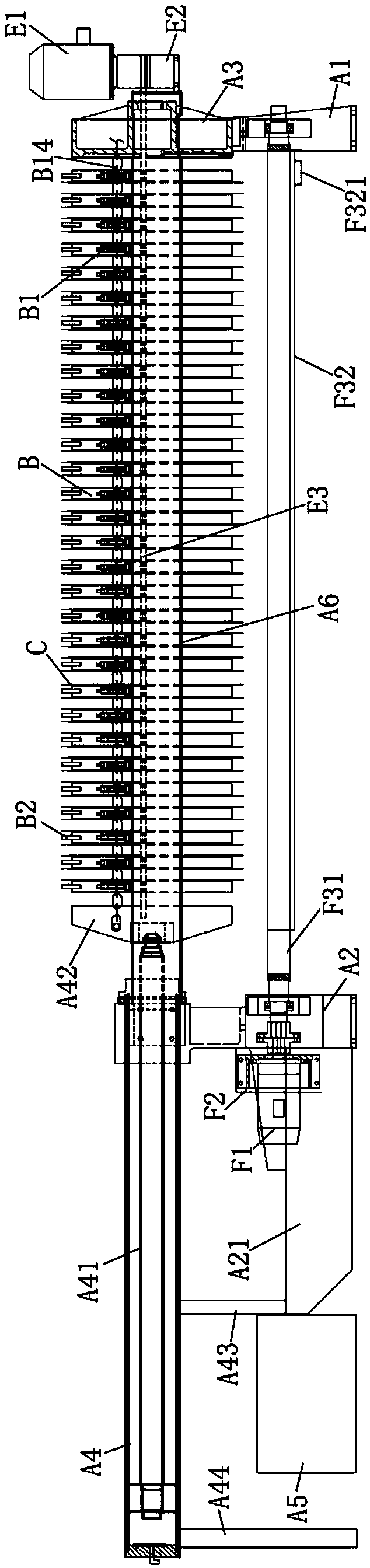

[0062] like figure 1 , figure 2 , image 3 As shown in the figure, a quick-opening filter press is composed of a base A1, a water storage tank G, a flip-type water-receiving tank plate mechanism, a beam steel plate A6, a side wall baffle, a vibrating material shaking mechanism, and a horizontal pushing main cylinder A4. , cylinder support A2, hydraulic station A5, fixed baffle A3, horizontal movable top pressure plate A42, 30 vertical filter pressure plates, chain quick opening mechanism, 30 sets of filter cloth, filter cloth locking and pulping mechanism. is characterized by,

[0063] The cylinder support seat A2 and the base A1 are pulled parallel to the left and right. A fixed baffle A3 is welded on the top of the base A1. The central part of the fixed baffle A3 is integrally formed with a slurry inlet A31 with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com