A serial plasma cracking flow reactor and its operation method

A flow reactor, plasma technology, applied in chemical instruments and methods, refining by particle radiation, chemical/physical/physical-chemical processes using energy, etc., can solve problems such as single research content, and achieve compact structure and design. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

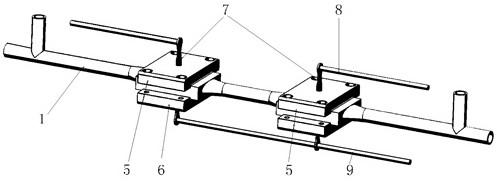

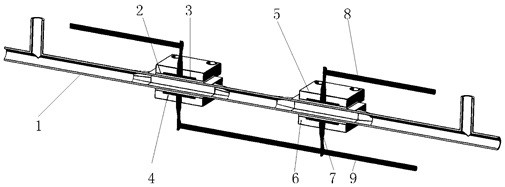

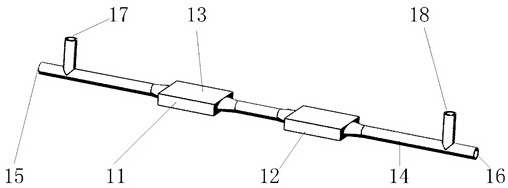

[0029] refer to Figure 1-Figure 9 , a series plasma cracking flow reactor, including series flow tube, medium layer, high-voltage copper plate, low-voltage copper plate, upper electrode shell, lower electrode shell, electrode transfer ear, high-voltage electrode and ground electrode ; The series flow tube includes a primary cracking device, a secondary cracking device, an electrode fixing surface, a circular tube, an observation window, a temperature measuring port, a fuel inlet and a product outlet, and the primary cracking device and the secondary cracking device are located in the series In the middle of the flow tube, the distance between the primary cracking device and the secondary cracking device is 30-70mm. The inside of the primary cracking device and the seco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap