Gas phase sample bottle automatic cleaning device and operating method thereof

An automatic cleaning and sample bottle technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of long time, low efficiency, operator injury, etc., to liberate manpower and improve experiments. Efficiency, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

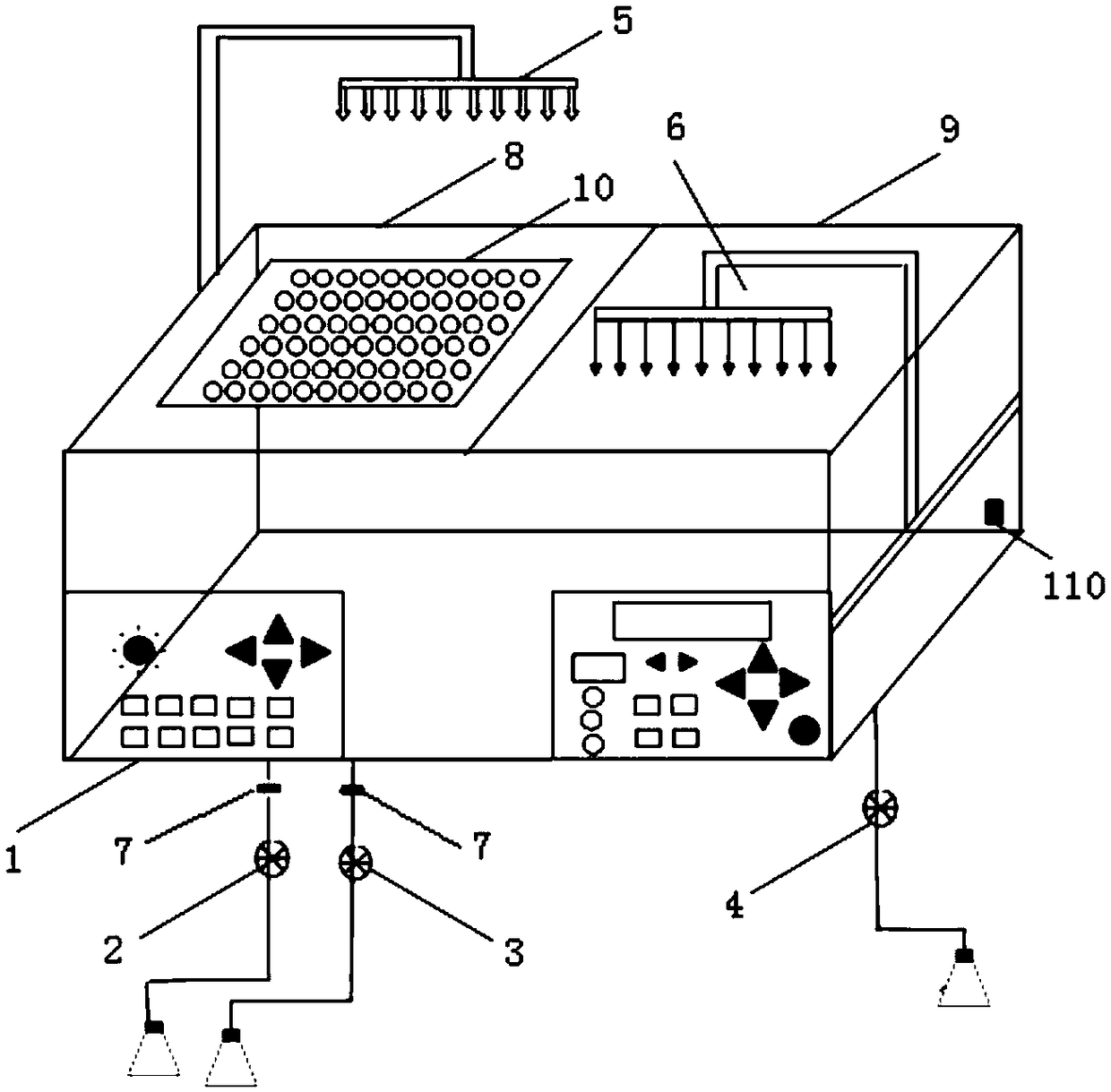

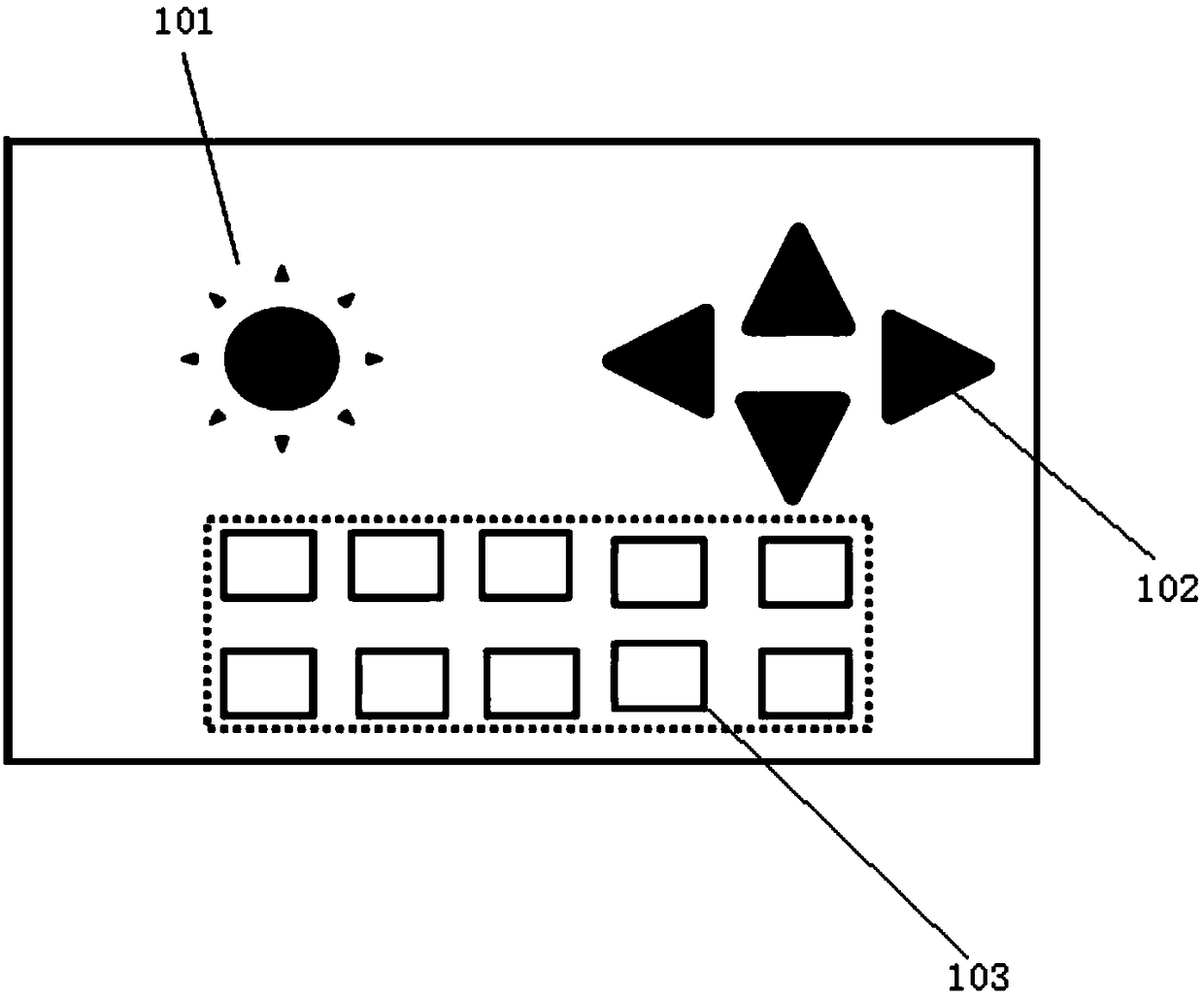

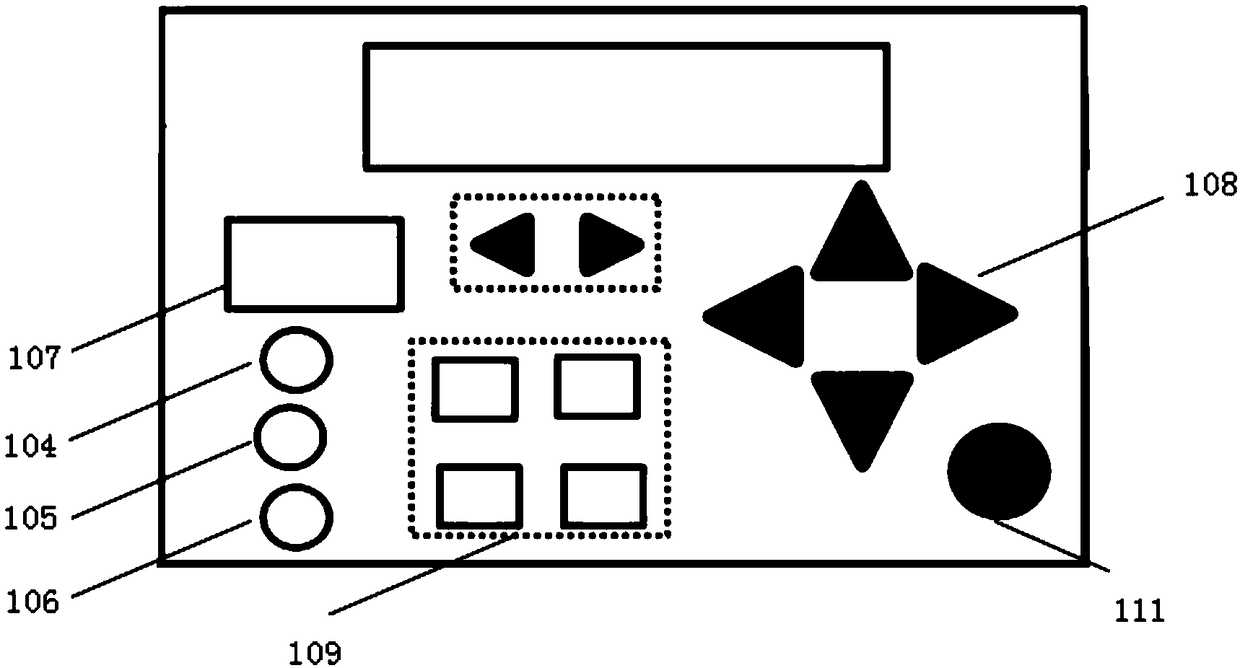

[0029] As shown in the figure, the gas-phase sample bottle automatic cleaning device includes an ultrasonic machine 1, a liquid inlet pump 2, a water pump 3, a waste liquid pump 4, a liquid inlet probe 5, a liquid suction probe 6, a flow valve 7 and a controller. The outer wall of the machine 1 is provided with a display screen and function keys, and the inside of the ultrasonic machine 1 is divided into two chambers, one is an ultrasonic cleaning sample bottle chamber 8, and the other is a waste liquid chamber 9; the ultrasonic cleaning sample bottle chamber 8 and The upper part of the waste liquid chamber 9 is provided with a loam cake, and the inside of the ultrasonic cleaning sample vial chamber 8 is provided with a sample tray 10; Position sensor; the liquid inlet probe 5 is installed above the ultrasonic machine 1 through a mechanical arm, and the liquid inlet end of the liquid inlet probe 5 is connected to the liquid outlet of the three-way I; one of the inlets of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com