Method of monitoring laser welding of plastic

A laser welding and laser technology, which is applied in the monitoring field of laser welding plastics, can solve the problems of lack of online monitoring, reducing production efficiency, and increasing processes in laser plastic welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

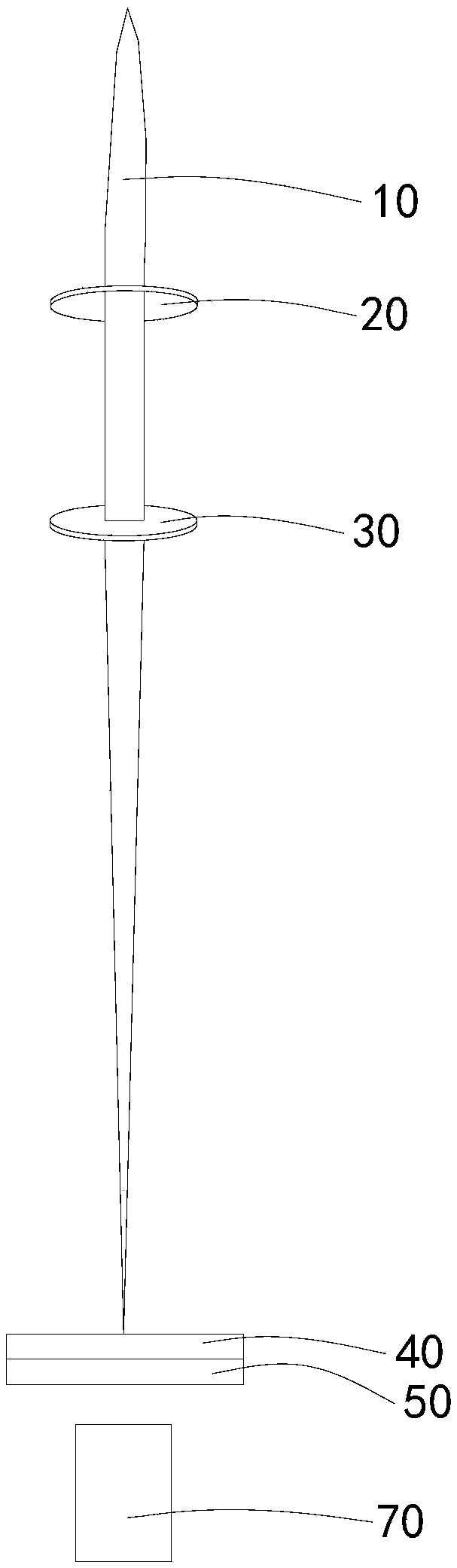

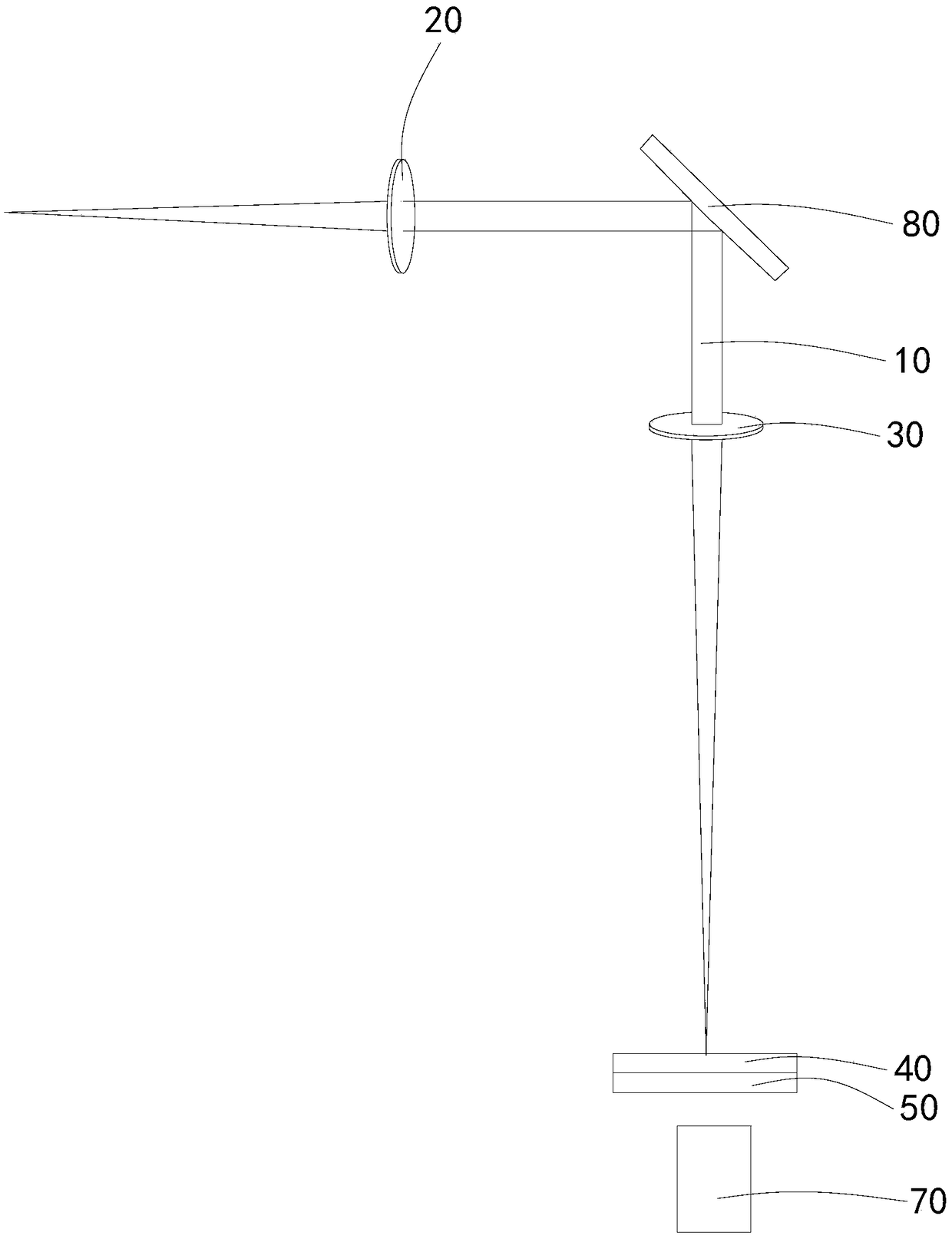

[0043] Please refer to figure 1 , the present invention provides a kind of monitoring method of laser welding plastic, is used for monitoring the yield rate of plastic welding namely upper plastic layer 40 and lower plastic layer 50 welding, when plastic welding, adopt laser 10 to pass through a collimating lens 20, and then Focusing is carried out through a focusing lens 30, and finally passes through the upper plastic layer 40 and the lower plastic layer 50, and part of the energy is absorbed by the upper plastic layer 40 and the lower plastic layer 50. The monitoring method includes the following steps:

[0044] The laser probe 70 is used to detect the energy value of the laser passing through the lower plastic layer 50; the energy value of the laser is compared with the preset value of the laser energy, and when the energy value of the laser is within the preset value range, the upper plastic layer 40 The welding with the lower plastic layer 50 is successful; when the ener...

Embodiment 2

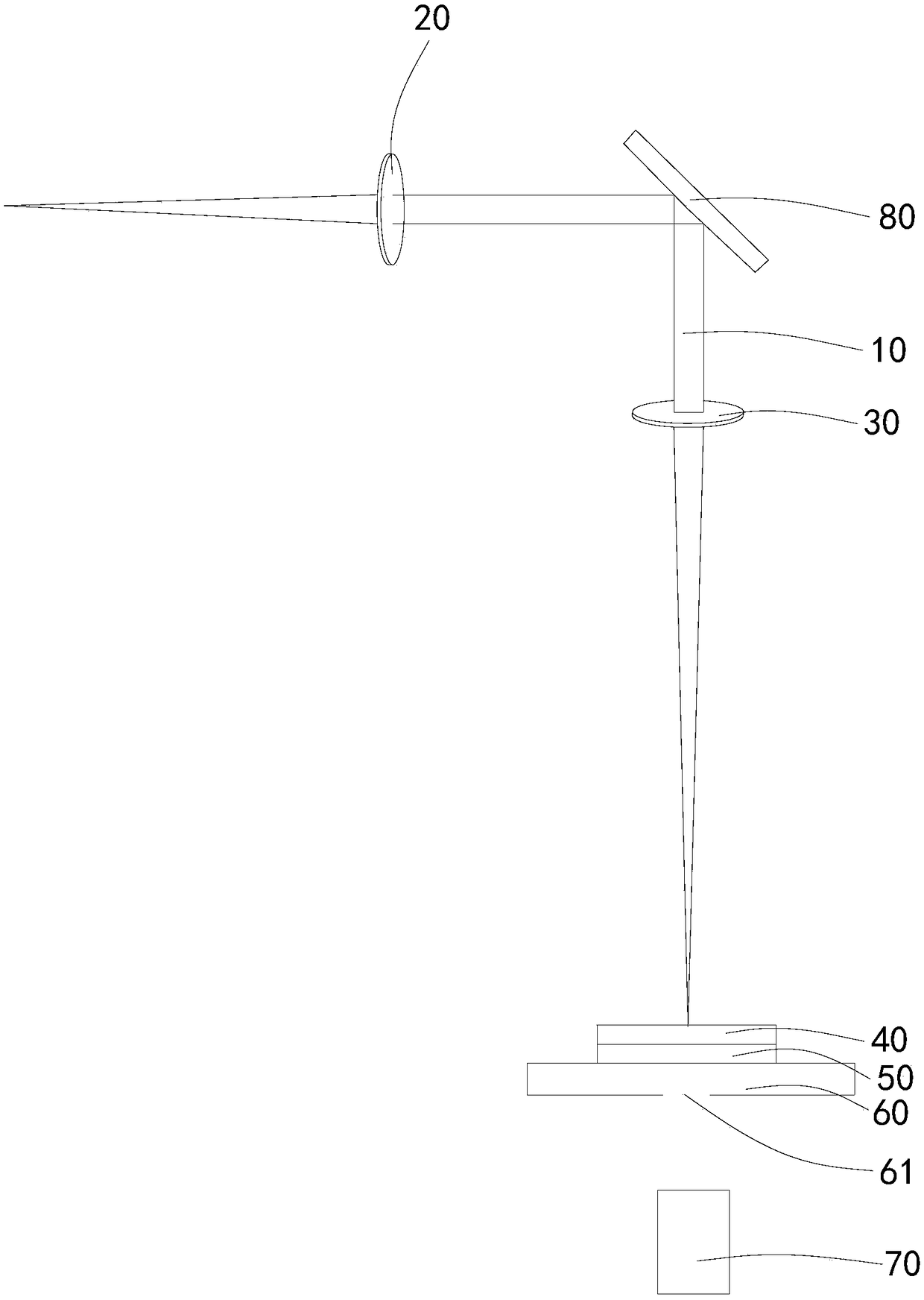

[0052] Please refer to image 3 , different from Embodiment 1, a monitoring method for laser welding plastics is provided, comprising the steps of:

[0053] A reflective layer 60 is set on the side of the lower plastic layer 50 away from the upper plastic layer 40, and at least one light transmission hole 61 is opened in the reflective layer 60, and the reflective layer 60 reflects the laser light 10 passing through the lower plastic layer 50 to pass through the lower plastic again. Layer 50, upper plastic layer 40, and part of the laser light passes through the light-transmitting hole 61 and passes through the reflective layer 60; the laser probe 70 is used to detect the energy value of the laser light passing through the light-transmitting hole 61; Compared with the preset value, when the energy value of the laser is within the preset value range, the upper plastic layer 40 and the lower plastic layer 50 are successfully welded; when the laser energy value exceeds the preset...

Embodiment 3

[0062] Please refer to image 3 , different from Embodiment 2, a monitoring method for laser welding plastics is provided, comprising the steps of:

[0063] An absorbing layer 60 is arranged on the side of the lower plastic layer 50 away from the upper plastic layer 40, and at least one light-transmitting hole 61 is opened in the absorbing layer 60. The absorbing layer 60 absorbs the laser light 10 passing through the lower plastic layer 50, and a small part of the laser light Pass through the light-transmitting hole 61 to pass through the absorbing layer 60; adopt the laser probe 70 to detect the energy value of the laser light passing through the light-transmitting hole 61; compare the energy value of the laser with the preset value of the laser energy, the energy value of the laser is at When the value is within the preset value range, the upper plastic layer 40 and the lower plastic layer 50 are successfully welded; when the energy value of the laser exceeds the preset val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com