A suspension suspension method for a train motor

A suspension type, train technology, applied in the direction of locomotive propulsion, motor-driven transmission, locomotive, etc., can solve the problem that the elastic damping element cannot meet the requirements of the motor hanging, achieve low deflection and torsional stiffness, and realize injection molding. The effect of glue positioning and improving fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

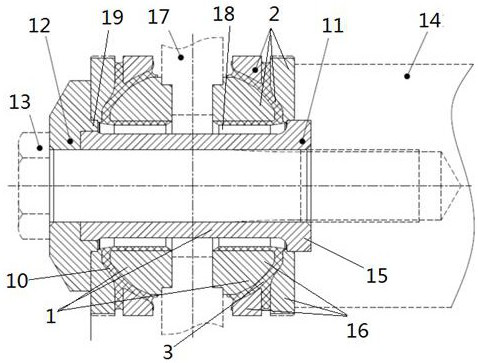

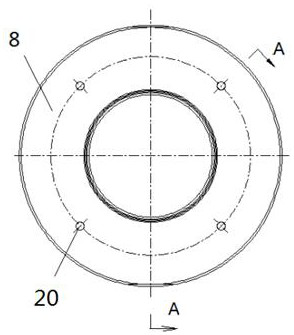

[0034]As can be seen from the accompanying drawings, the present invention relates to a method for hanging a suspension train motor, in which the train motor is suspended on the bogie crossbeam mount 17 of the train through an elastic composite elastic element 1; the elastic composite elastic element 1 is a suspended combined elastic part, the train motor 14 is suspended on the bogie beam mounting seat 17 by the suspended combined elastic part, and the suspended combined elastic part is connected with the train motor 14 through a fastener 13 to form a train Motor suspension suspension.

[0035] The suspended combined elastic member 1 is composed of two elastic elements 2. The two elastic elements 2 are clamped on the bogie in a suspended manner from both sides of the bogie beam mounting seat 17, and are combined by fasteners 13. Together, a suspended combined elastic member is formed.

[0036] The suspended combined elastic member is axially connected with the train motor 14 ...

Embodiment 2

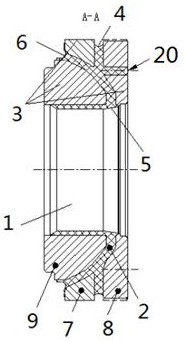

[0045] The principle of the second embodiment is the same as that of the first embodiment, only slightly different in structure. It is a suspension type train motor hanging method, the train motor is suspended on the bogie of the train through an elastic composite elastic element; The suspended parts are suspended on the bogie, and the suspended combined elastic parts are connected with the train motor through fasteners to form the suspended suspension of the train motor.

[0046] The suspended combined elastic part is composed of two elastic elements. The two elastic elements are clamped on the bogie in a suspended manner from both sides of the bogie, and are combined by fasteners to form a suspended combined elastic pieces.

[0047] The suspended combined elastic member is axially connected with the train motor through fasteners, so that the train motor is suspended on the bogie through the suspended combined elastic member.

[0048] The two elastic elements of the suspend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com