Waste classifying collecting device in industrial production

A collection device and waste technology, which is applied in the field of waste classification collection devices, can solve the problems of inconvenient classification collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

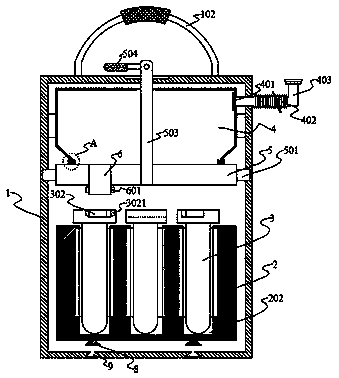

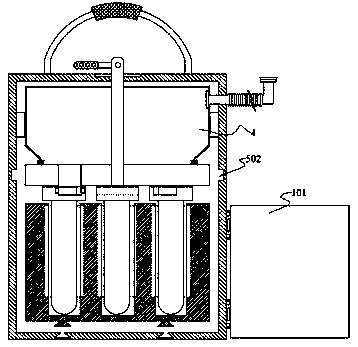

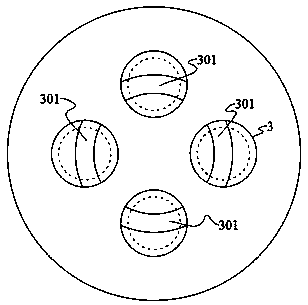

[0032] The waste sorting and collecting device in industrial production of the present invention comprises a housing 1, a door panel 101 is hinged on the side wall of the lower end of the housing 1, a handle 102 is provided at the upper end of the housing 1, and a handle 102 is provided at the lower end of the housing 1. There is a placement frame 2, and the placement frame 2 is provided with a plurality of annularly arranged placement holes 202, and a collection barrel 3 is arranged in the placement hole 202, and the upper end of the annular arrangement of collection barrels 3 is provided with a combination to form an annular chute 302. The upper end of the housing 1 is provided with a collecting cover 4, the collecting cover 4 is provided with a liquid inlet 401, and the lower end of the collecting cover 4 is rotatably connected with a rotating plate 5, and the rotating plate 5 is provided with a connection with the collecting cover 4. The guide tube 6, the lower end of the g...

Embodiment 2

[0035] This embodiment is further optimized on the basis of Embodiment 1 as follows: the side wall of the chute 302 is provided with a guide groove 3021, and the outer wall of the guide tube 6 is provided with a guide block that matches the guide groove 3021 601.

[0036] After adopting this technical scheme, the guide groove 3021 cooperates with the guide block 601 to ensure the stability of the rotation of the rotation plate 5 when the rotation plate 5 is rotated by the handle 504, and the guide tube 6 will not break away from the chute 302, ensuring The waste liquid directly enters the collection barrel 3 without the waste liquid getting out of the collection barrel 3 .

Embodiment 3

[0038] This embodiment is further optimized on the basis of Embodiment 1 as follows: the upper end of the rotating plate 5 is provided with an annular limiting groove 7, the lower end of the collecting cover 4 extends into the limiting groove 7, the A sealing ring 701 is provided between both sides of the collection cover 4 and the inner wall of the limiting groove 7 .

[0039] After adopting this technical solution, through the function of the sealing ring 701, it is ensured that the waste liquid in the collection cover 4 will not enter the collection bucket 3 through the gap between the rotation plate 5 and the lower end of the fixed cover during the rotation of the rotating plate 5 outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com