Micromechanical electrostatically driven curved comb tooth structure

A technology of electrostatic drive and comb-tooth structure, applied in the direction of microstructure technology, microstructure device, generator/motor, etc., can solve the problems of reducing the driving voltage of the structure, achieve a large driving stroke, increase the volume of the cavity, and lateral stroke The effect of increased distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

[0022] The present invention provides an arc-shaped comb tooth structure driven by micro-mechanical electrostatics, which realizes that under the same vacuum environment and driving voltage as the traditional technology, the mechanical movement displacement is increased, and the process difficulty is not increased.

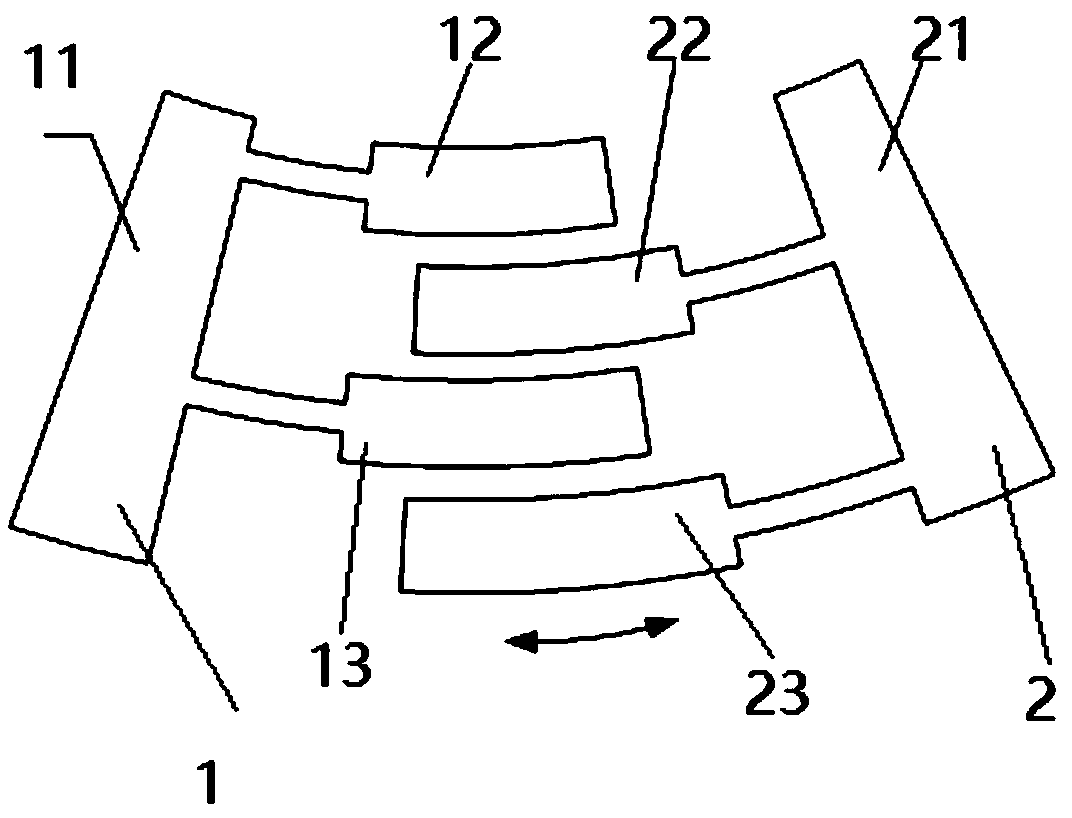

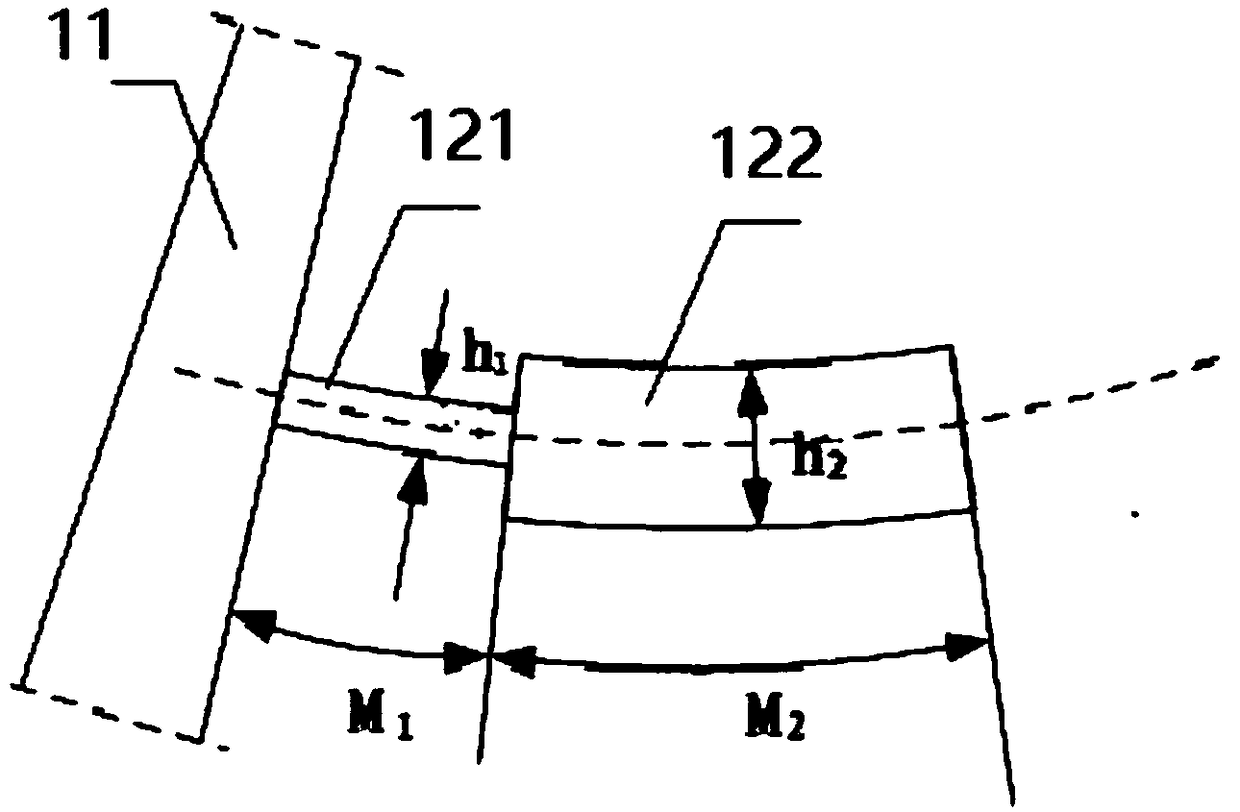

[0023] Such as figure 1 Shown is a schematic diagram of the arc comb tooth group structure. It can be seen from the figure that a micromechanical electrostatically driven arc comb tooth structure includes n groups of the same arc comb tooth groups; n groups of arc comb tooth groups are evenly distributed on the outside The outer edge of the arc-shaped device; each group of arc-shaped comb teeth includes a static comb tooth 1 and a movable comb tooth 2; the static comb tooth 1 and the movable comb tooth 2 are a staggered F-shaped hammer stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com