A Magnetic Latching Solenoid Controlled Microwave Switch Driving System

A microwave switch and drive system technology, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of large power consumption and achieve the effect of large driving stroke, high efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

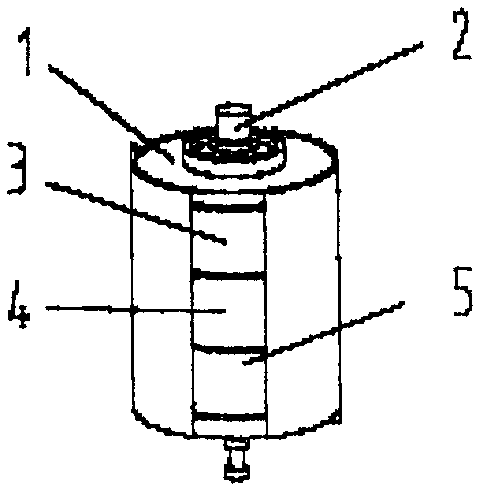

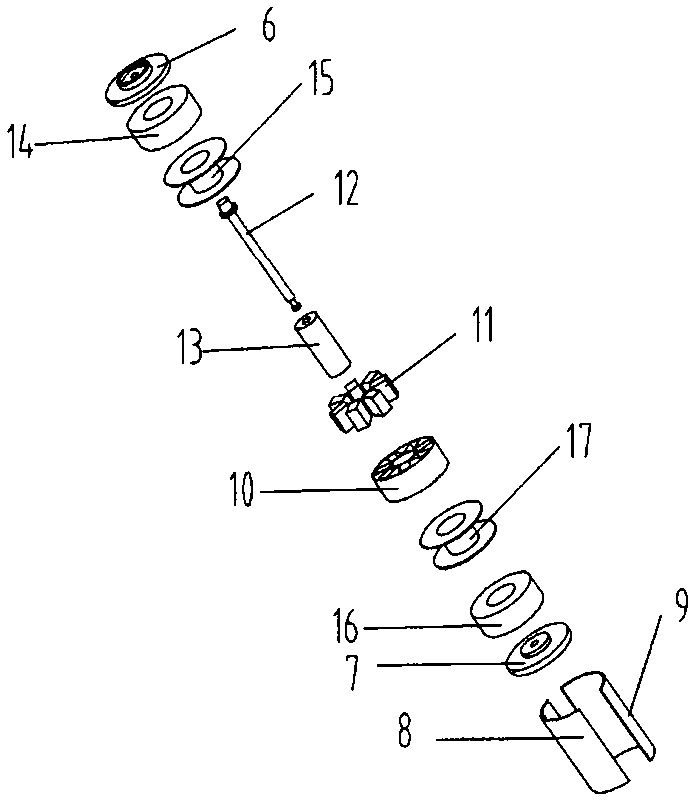

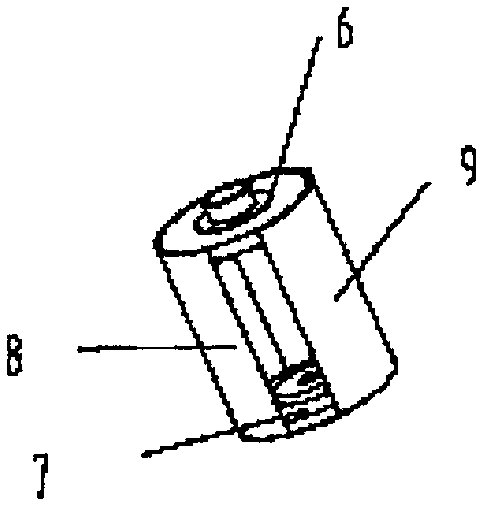

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the driving system of the present invention mainly includes a yoke group 1, an iron core group 2, an upper coil group 3, a magnetic steel array group 4, and a lower coil group 5, which jointly form a magnetic path. The yoke group 1 includes an upper yoke 6 , a lower yoke 7 , a left yoke 8 and a right yoke 9 . The magnetic steel array group 4 includes a magnetic steel fixing frame 10 and a magnetic steel array 11 . The iron core group 2 includes an iron core 12 and a transmission shaft 13 . The upper coil assembly 3 includes an upper coil frame 15 and an upper coil 14 wound on the upper coil frame 15 . The lower coil set 5 includes a lower coil frame 17 and a lower coil 16 wound on the lower coil frame 17. The two coils each lead to two terminals.

[0016] The magnetic steel array group 4 is composed of massive magnetic steel, which is evenly distributed on the circumference and concentric to the center,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com