A kind of copper surface phosphate ester assembly liquid and its application

A technology of surface phosphoric acid and assembly solution, applied in the chemical industry, can solve the problems of easy corrosion of copper surface, and achieve the effects of low cost, reduced dosage and shortened processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

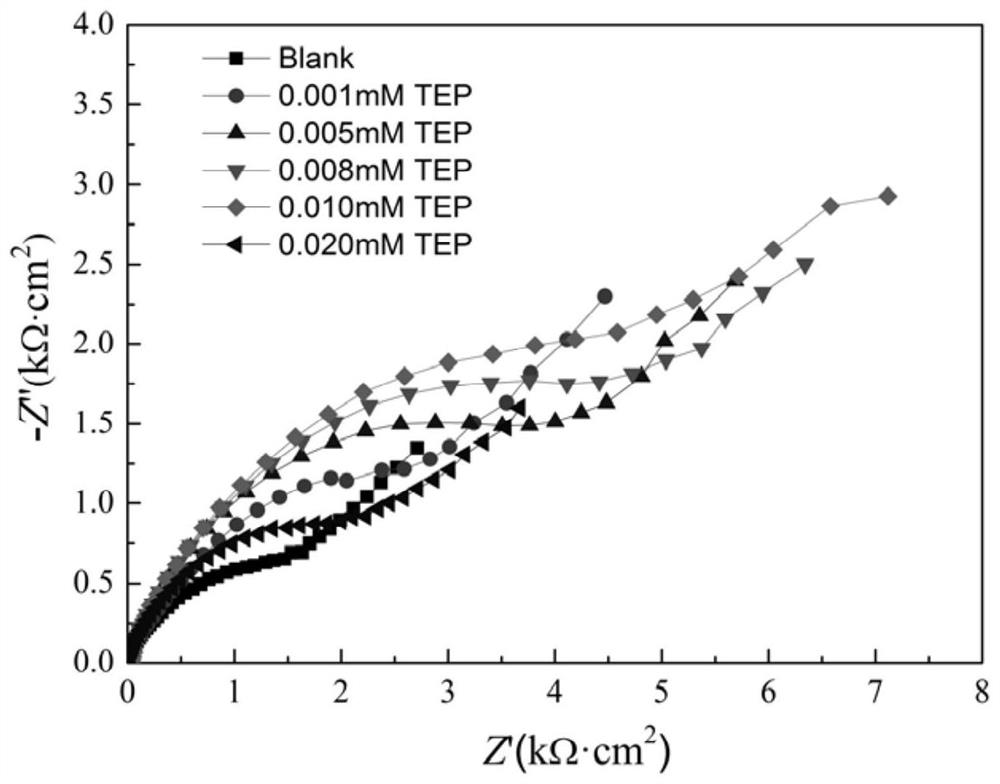

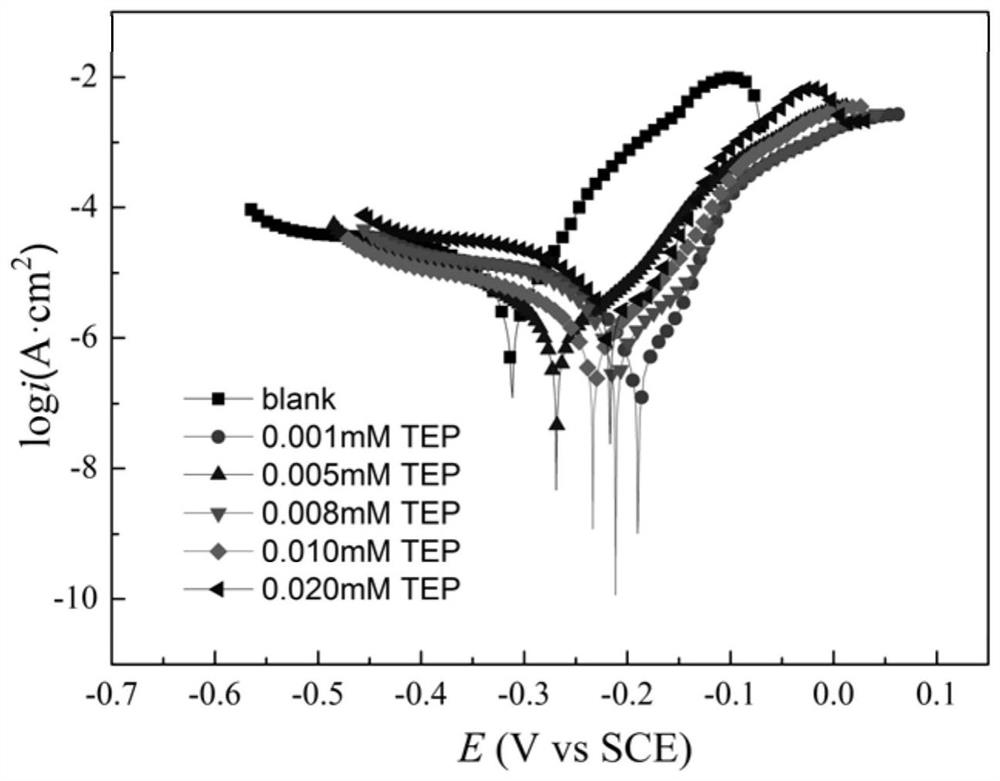

[0047] The copper surface phosphate ester assembly solution in this embodiment is triethyl phosphate assembly solution of different concentrations, the solvent is ethanol, and the concentrations of triethyl phosphate are 0.001, 0.005, 0.008, 0.01 mM, 0.02 mM respectively.

[0048] The preparation method of phosphate ester assembly film on copper surface is:

[0049] (1) Grind the 0.5cm×1.0cm copper sheet step by step with 400, 800, 1600 and 2000 mesh metallographic sandpaper, and then polish it with 5μm, 3.5μm, 2.5μm and 1.5μm polishing paste, and use ethanol Decontamination and degreasing treatment, then wash with deionized water, and set aside; (2) Immerse the rinsed copper sheet in triethyl phosphate assembly solution for 1h assembly, the assembly temperature is room temperature, and the surface-to-volume ratio is 20mL / cm 2 , to obtain a phosphate-based assembled film on the copper surface.

[0050] Soak the phosphate ester assembly film on the copper surface in 3wt.% NaCl...

Embodiment 2

[0055] The copper surface phosphate ester assembly solution in this embodiment is triethyl phosphate assembly solution with different concentrations, the solvent is ethanol, and the concentration of triethyl phosphate is 0.01 mM respectively.

[0056] The preparation method of phosphate ester assembly film on copper surface is:

[0057] (1) Grind the 0.5cm×1.0cm copper sheet step by step with 400, 800, 1600 and 2000 mesh metallographic sandpaper, and then polish it with 5μm, 3.5μm, 2.5μm and 1.5μm polishing paste, and use ethanol Decontamination and degreasing treatment, then wash with deionized water, and set aside; (2) Immerse the rinsed copper sheet in triethyl phosphate assembly solution for 1h, the assembly temperature is 35°C, and the surface-to-volume ratio is 50mL / cm 2 , to obtain a phosphate-based assembled film on the copper surface.

Embodiment 3

[0059] The copper surface phosphate ester assembly solution in this embodiment is triethyl phosphate assembly solution with different concentrations, the solvent is ethanol, and the concentration of triethyl phosphate is 0.01 mM respectively.

[0060] The preparation method of phosphate ester assembly film on copper surface is:

[0061] (1) Grind the 0.5cm×1.0cm copper sheet step by step with 400, 800, 1600 and 2000 mesh metallographic sandpaper, and then polish it with 5μm, 3.5μm, 2.5μm and 1.5μm polishing paste, and use ethanol Decontamination and degreasing treatment, then wash with deionized water, and set aside; (2) Immerse the rinsed copper sheet in triethyl phosphate assembly solution for 5 hours, the assembly temperature is 5°C, and the surface-to-volume ratio is 40mL / cm 2 , to obtain a phosphate-based assembled film on the copper surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com