Planetary speed reduction and gear shifting mechanism and automobile

A planetary deceleration and shifting mechanism technology, applied in the field of automobile transmission system, can solve the problems of the maximum speed limit of the input end of the gear train, the wear power of the planetary mechanism 2, and the loss, so as to improve the success rate of shifting, reduce the shifting force, Realize the effect of time difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

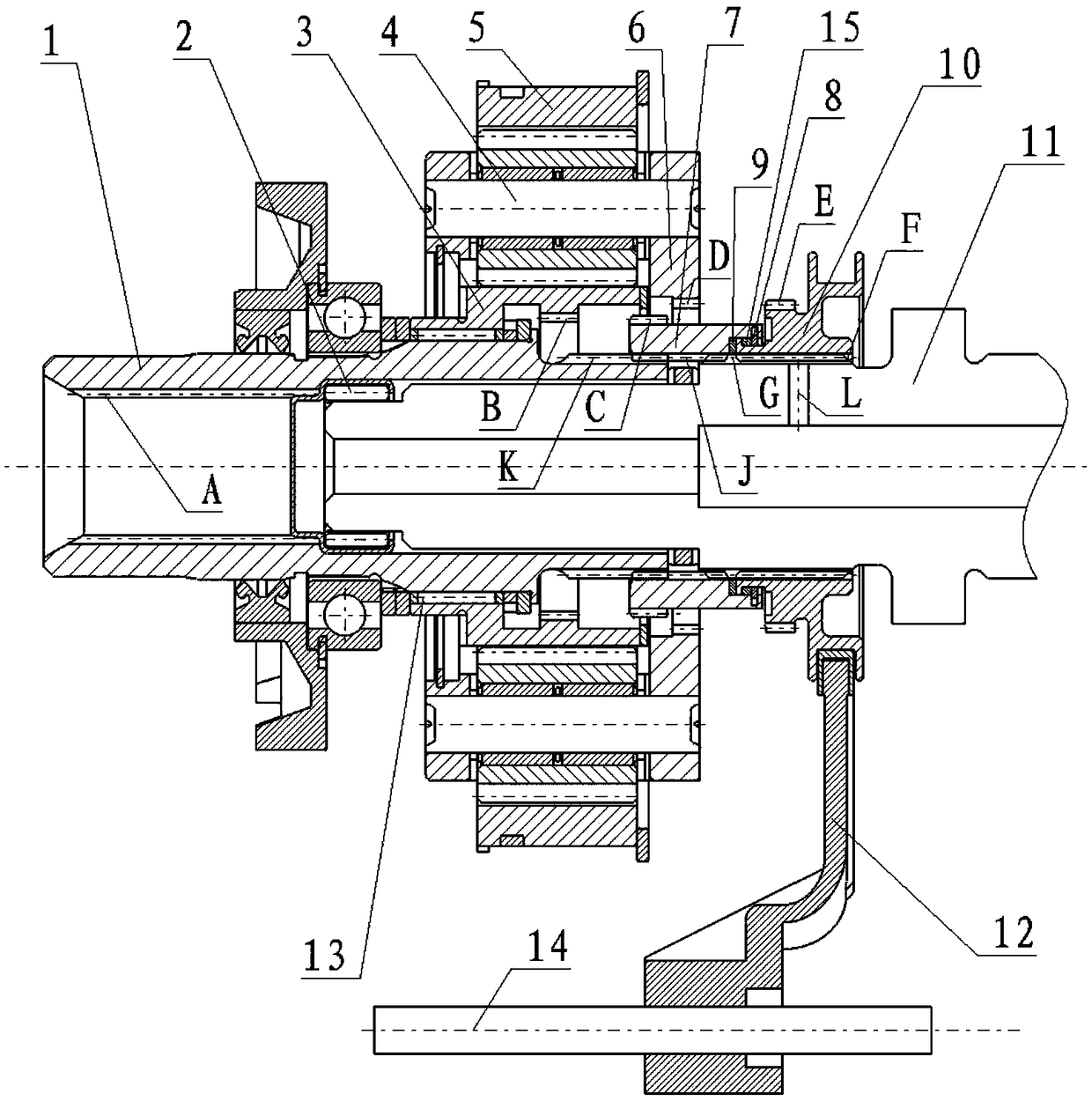

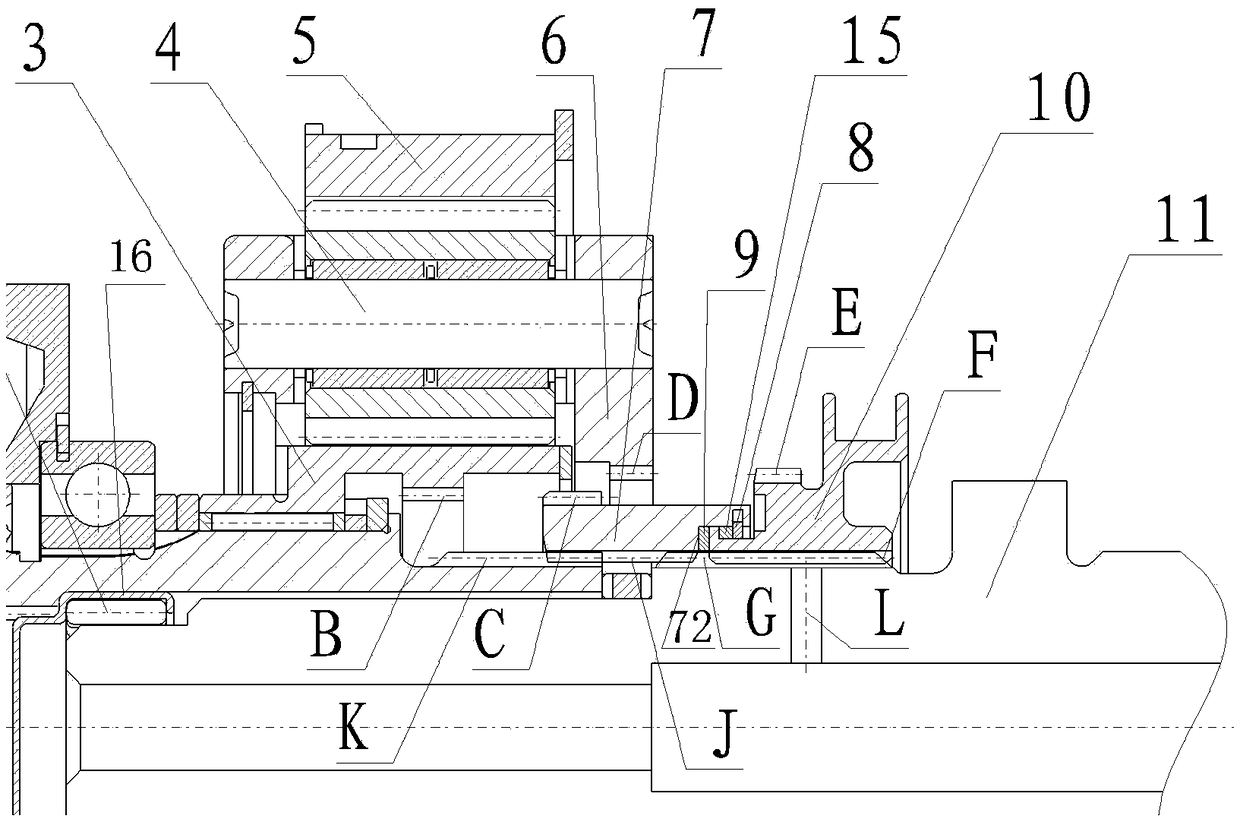

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

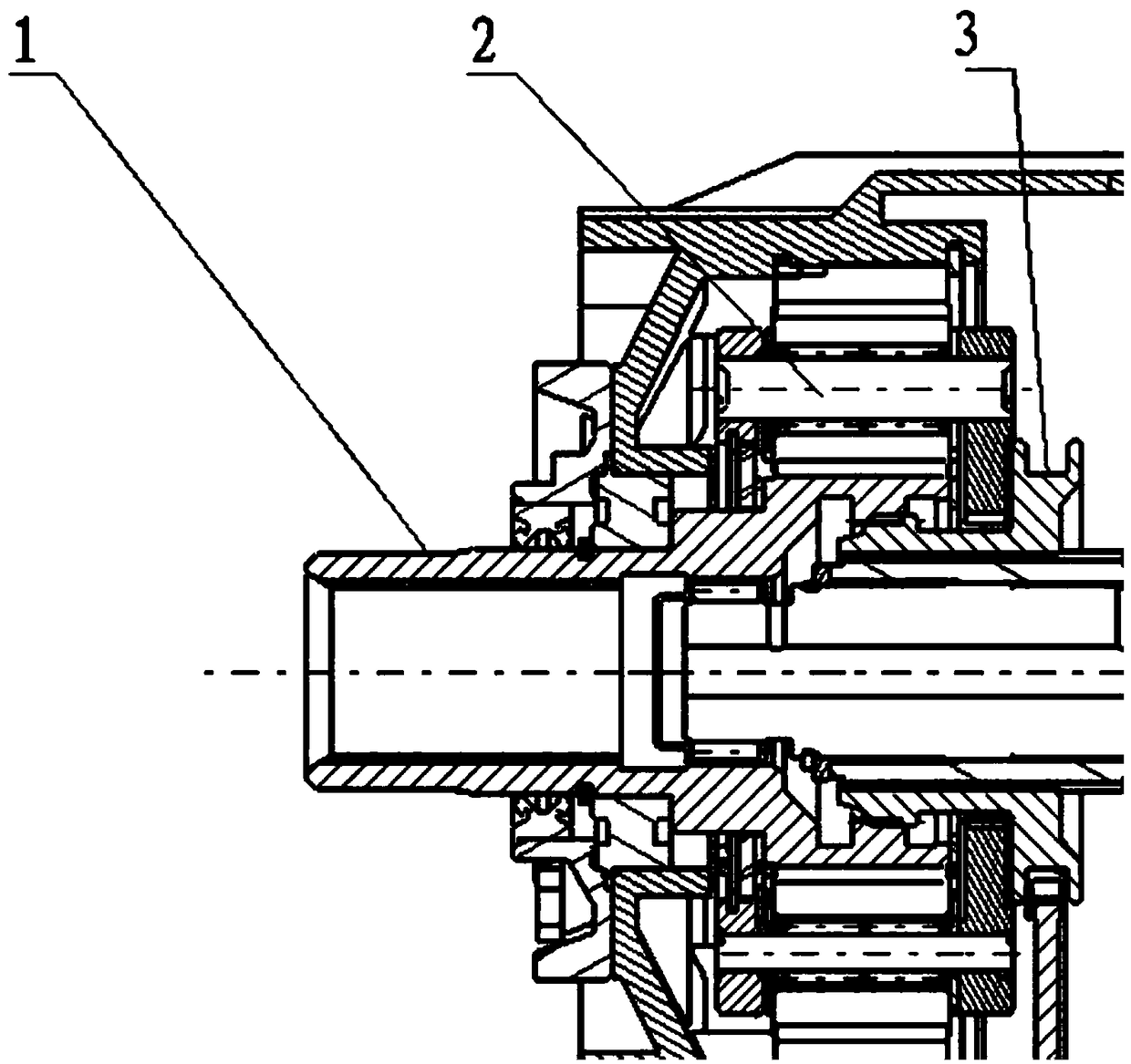

[0038] Such as figure 1 As shown, the present invention includes an input shaft 1 and an output shaft 11 arranged coaxially, the input shaft 1 supports the sun gear 3 of the planetary reduction mechanism, and a needle bearing 13 is arranged between the sun gear 3 and the input shaft 1; Wheel 3, planetary gear 4, ring gear 5, and planetary carrier 6 form a planetary reduction mechanism. Ring gear 5 is fixed on the housing, and it also includes a first sliding gear sleeve 7, which is used for input The shaft 1 meshes; the first sliding tooth sleeve 7 is also used to mesh or separate from the output shaft 11, or to mesh or separate from the sun gear 3;

[0039] The second sliding gear sleeve 10, the second sliding gear sleeve 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com