Small pneumatic stripping and cutting machine

A technology of cutting machine and cutting mechanism, which is applied in the direction of electrical components, cable installation devices, equipment for dismantling/armouring cables, etc. It can solve the problems of low work efficiency, cutting cable insulation layer, hand cutting, etc., and achieve production safety , simple operation, accurate cutting depth and length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

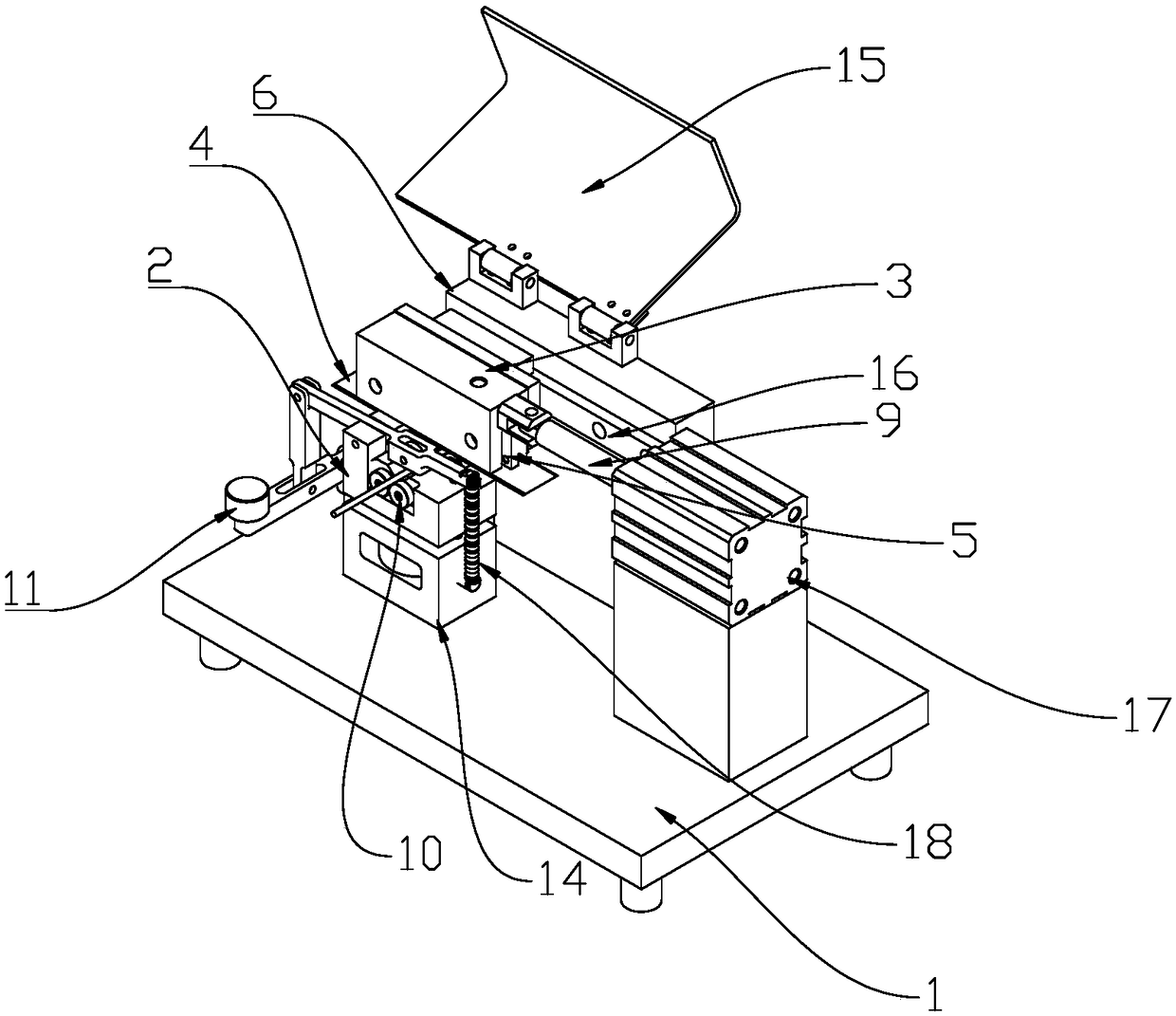

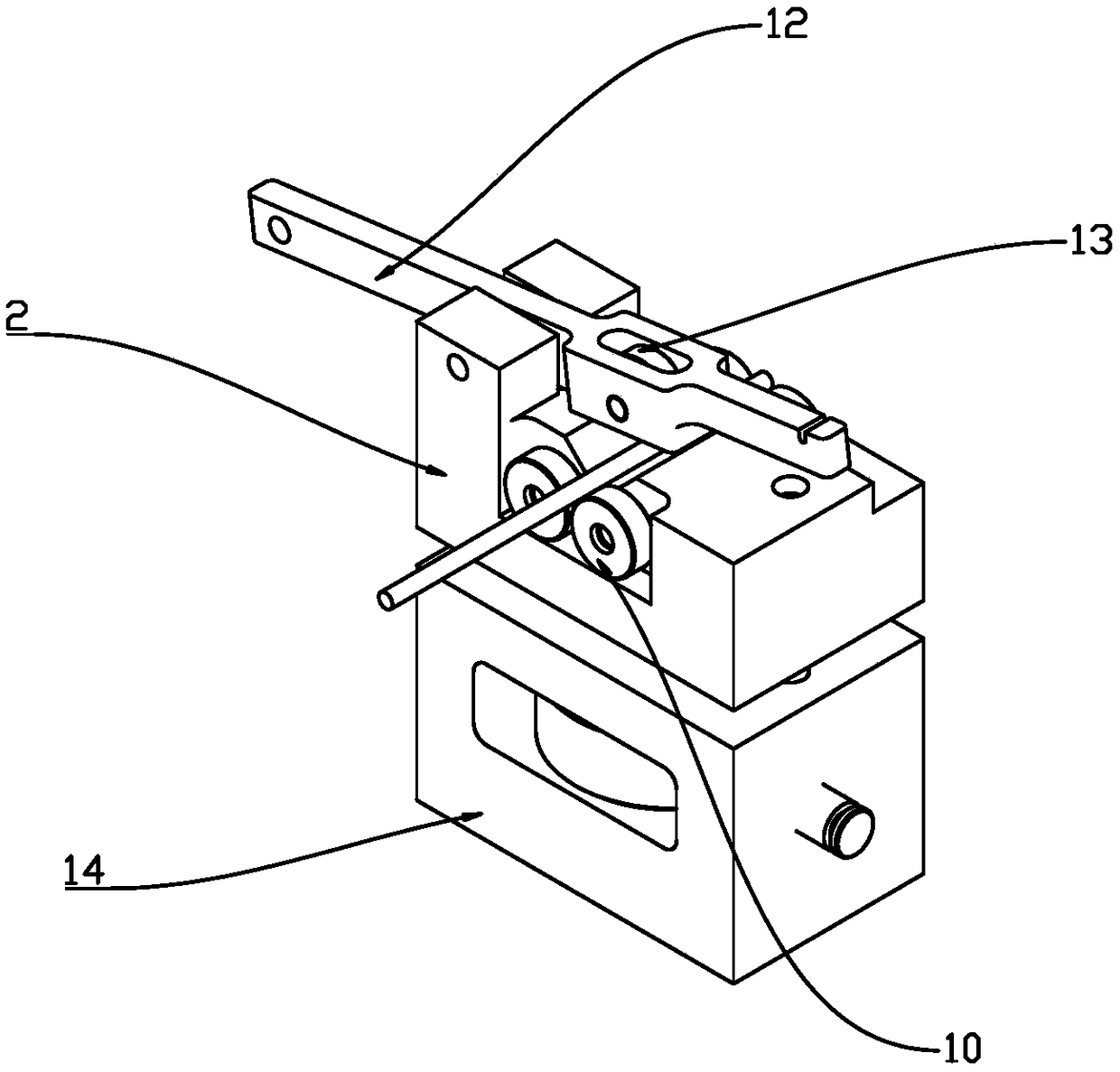

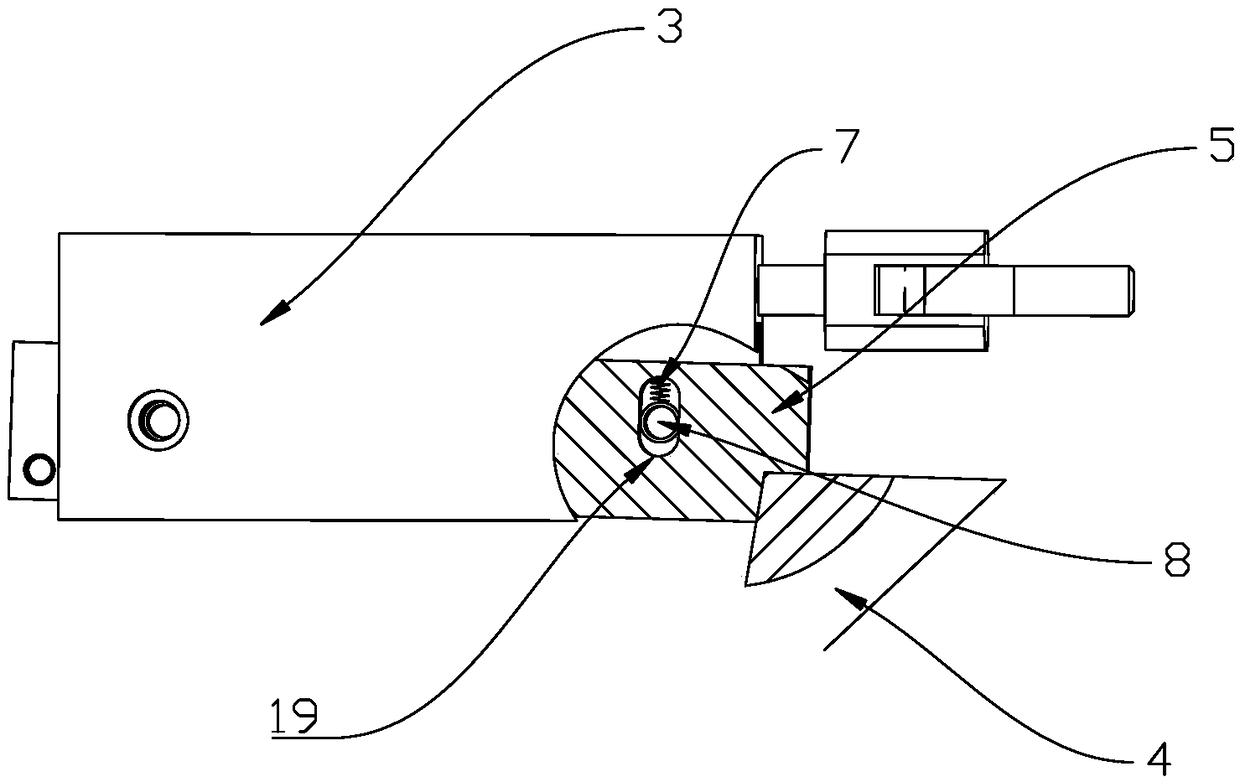

[0022] Such as figure 1 , a small pneumatic wire stripping and cutting machine, including a base 1, a cable support platform 2 and a cutting mechanism are arranged on the base 1, specifically, the cutting mechanism in the present invention is a tool holder 3 and a movable plate 5 hinged below it , the tool holder 3 is connected to the cylinder 17 through the cylinder connecting rod 9, the blade 4 is connected to the bottom of the movable plate 5 through the screws on both sides, the back of the tool holder 3 is slidably connected to the back plate 6 through a slider, and the back plate 6 is provided with a suitable The guide rail 16 of the guide rail 16 adopts the above-mentioned structure to conveniently control the position of the knife rest, so that it can be accurately moved to the corresponding position; There is a first spring 7, the end of the first spring 7 is connected to the connecting shaft 8, and the connecting shaft moves up and down in a small range through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com