Alloy powder mixing machine

An alloy powder and mixer technology, applied in mixers, mixers with rotating containers, mixer accessories, etc., can solve problems such as safety hazards, combustion, affecting the working environment of workshops, etc., to achieve production safety, reduce noise, and reduce temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

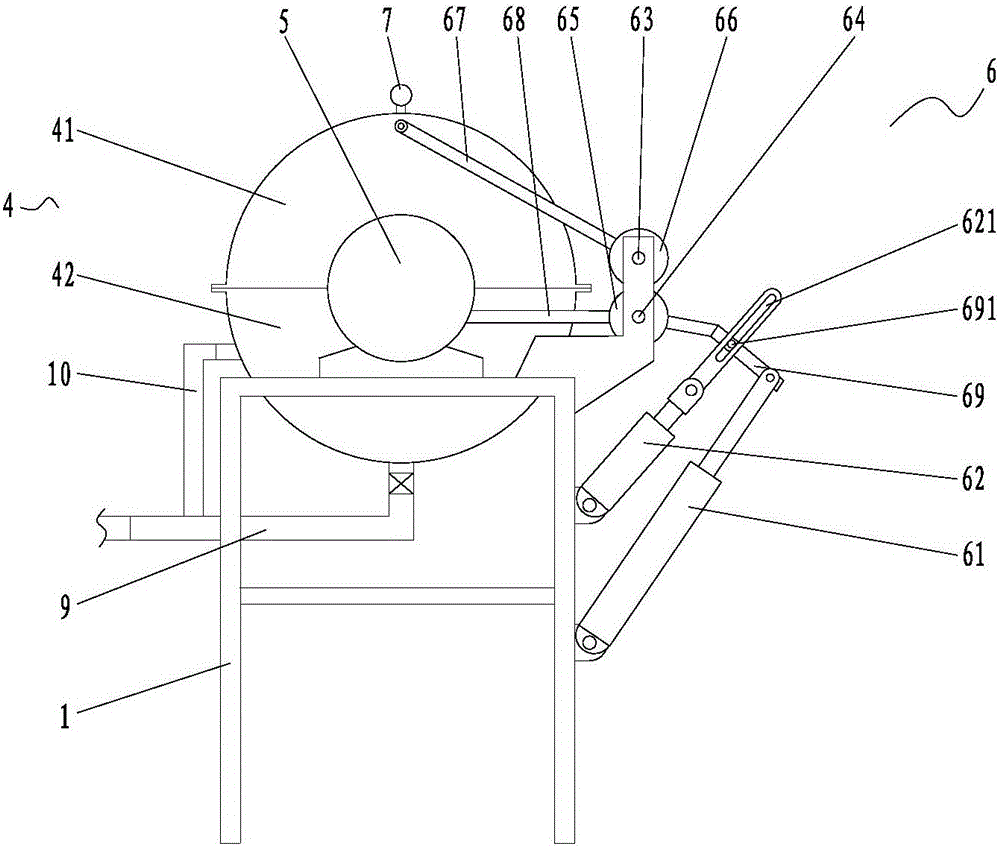

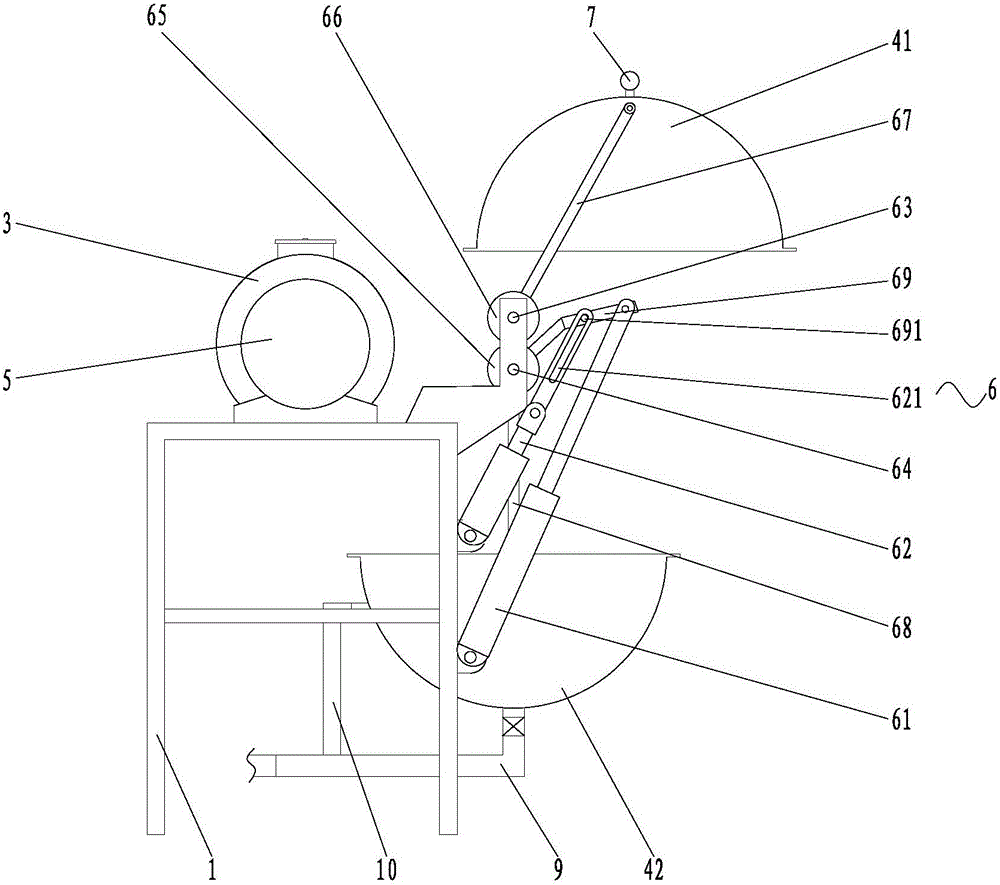

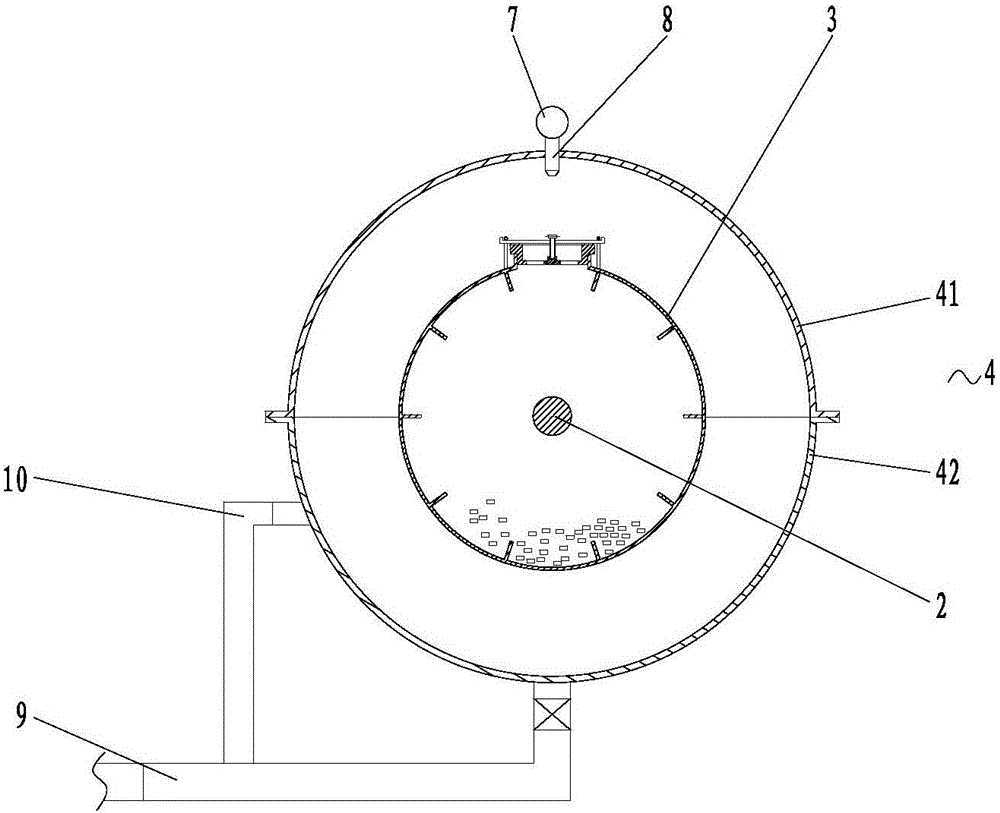

[0017] Such as Figure 1 to Figure 3 As shown in one of them, the present invention includes a frame 1, a main shaft 2, a mixing tank 3 and an outer cover 4, the main shaft 2 is rotatably connected to the frame 1, and is driven to rotate by a reduction motor 5, and the mixing tank 3 is fixedly sleeved on the main shaft 2 , and rotate synchronously with the main shaft 2, the outer cover 4 is located outside the mixing tank 3 and surrounds the mixing tank 3; the outer cover 4 includes an upper cover body 41 and a lower cover body 42, and the frame 1 is provided with a driving upper cover body 41 , the driving device 6 for closing or opening the lower cover body 42; the top of the upper cover body 41 is provided with a water inlet pipe 7, and the bottom of the water inlet pipe 7 is provided with a plurality of spray heads 8 extending into the upper cover body 41, and more Two shower heads 8 are arranged at equal intervals along the length direction of the water inlet pipe 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com