Auxiliary sand paving equipment for standing long jump

A technology of spreading sand and long jump, applied in water skiing, sports accessories, ice skating, etc., can solve the problems of excessive physical strength, trouble, and consumption, and achieve the effect of uniform sand filling and favorable leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

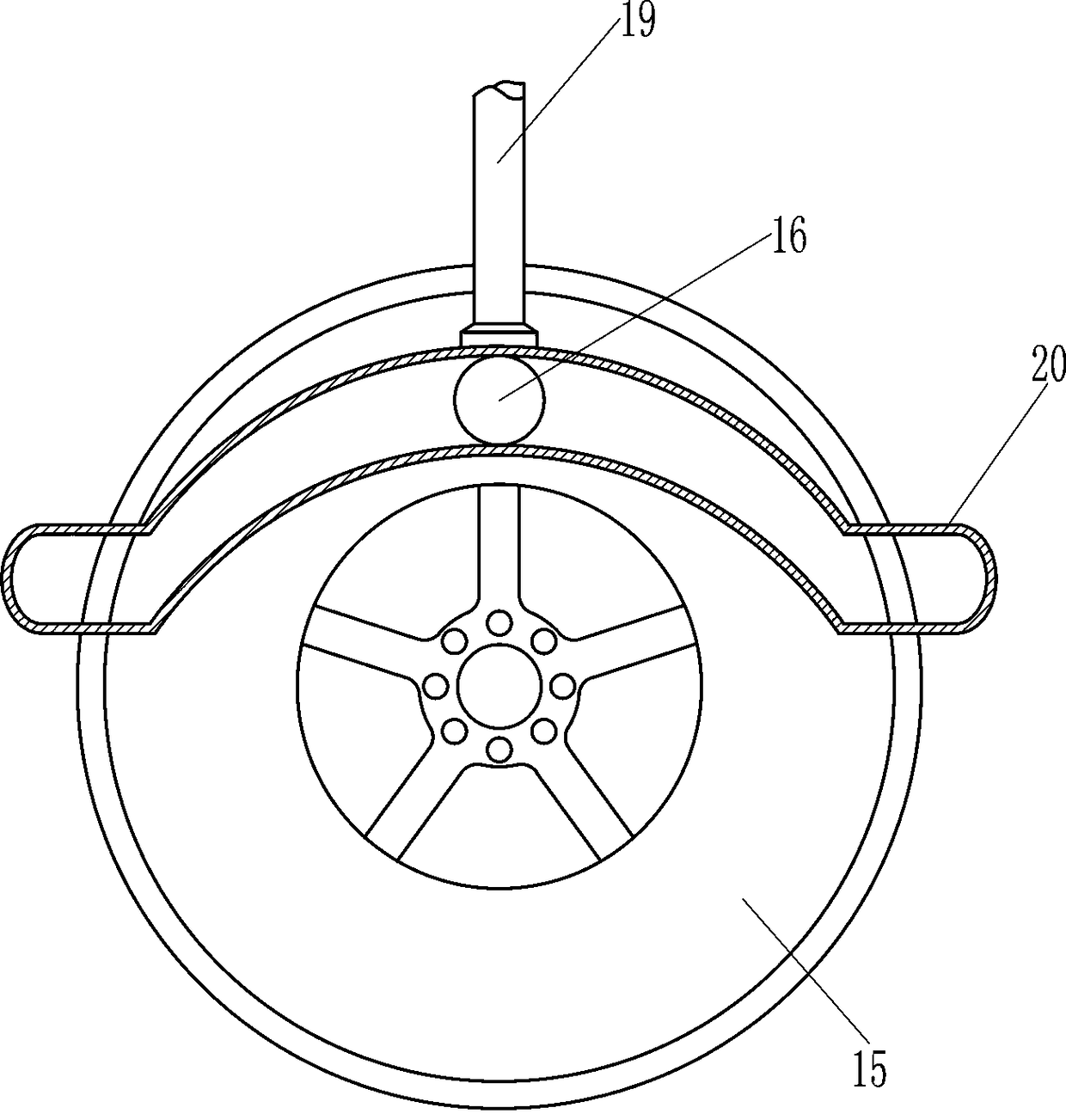

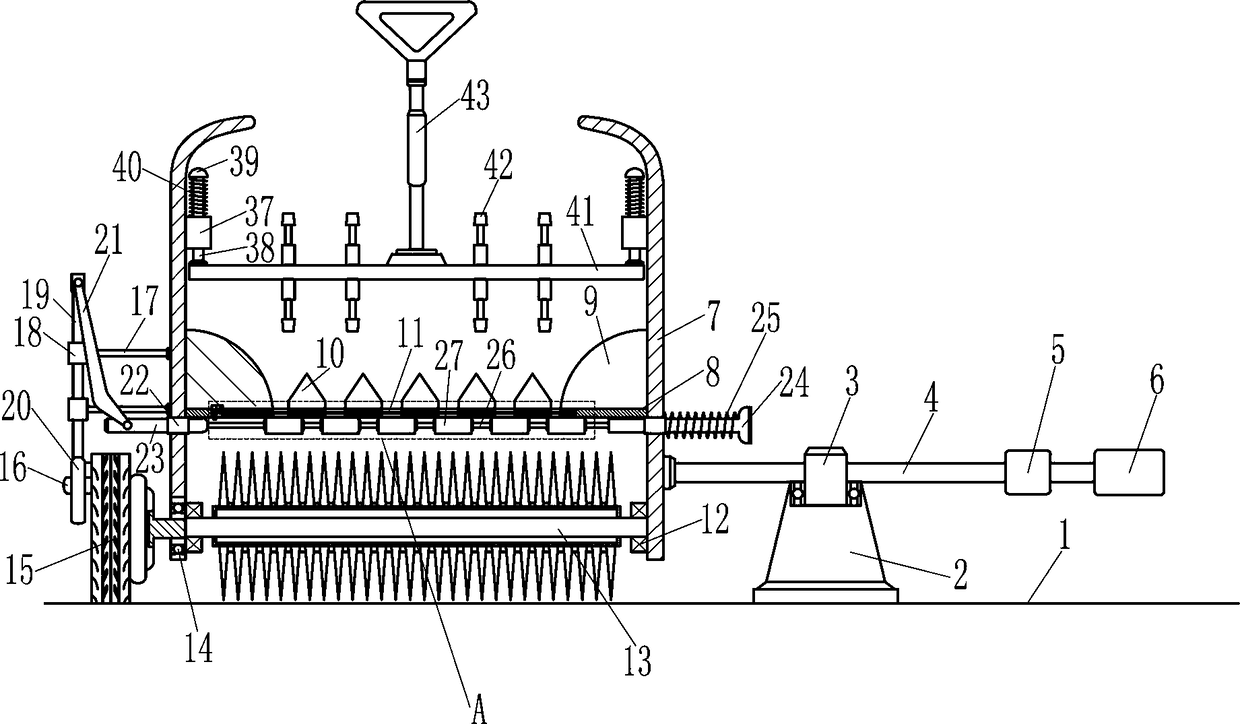

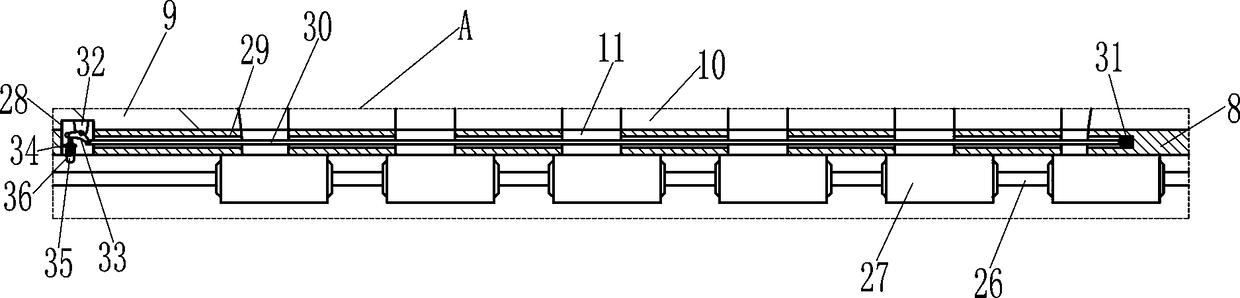

[0017] A kind of auxiliary sand dressing equipment for standing long jump, such as Figure 1-3As shown, it includes a first bearing seat 2, a rotating shaft 3, a push rod 4, a first handle 5, a second handle 6, a mounting frame 7, a mounting plate 8, an arc block 9, a tapered block 10, and a second bearing block 12 , stirring wheel 13, thrust bearing 14, patterned tire 15, first round bar 16, L-shaped pole 17, first guide sleeve 18, first guide bar 19, arc frame 20, first arc bar 21, the first Two guide sleeves 22, slide bar 23, T-bar 24, first spring 25, connecting rod 26 and block 27, the first bearing seat 2 is installed on the ground 1, and the rotating shaft 3 is installed on the first bearing seat 2, the rotating shaft 3 The upper part is connected with a push rod 4, the right part of the push rod 4 is provided with a first handle 5, the right end of the push rod 4 is provided with a second handle 6, the second handle 6 is located on the right side of the first handle 5,...

Embodiment 2

[0019] A kind of auxiliary sand dressing equipment for standing long jump, such as Figure 1-3 As shown, it includes a first bearing seat 2, a rotating shaft 3, a push rod 4, a first handle 5, a second handle 6, a mounting frame 7, a mounting plate 8, an arc block 9, a tapered block 10, and a second bearing block 12 , stirring wheel 13, thrust bearing 14, patterned tire 15, first round bar 16, L-shaped pole 17, first guide sleeve 18, first guide bar 19, arc frame 20, first arc bar 21, the first Two guide sleeves 22, slide bar 23, T-bar 24, first spring 25, connecting rod 26 and block 27, the first bearing seat 2 is installed on the ground 1, and the rotating shaft 3 is installed on the first bearing seat 2, the rotating shaft 3 The upper part is connected with a push rod 4, the right part of the push rod 4 is provided with a first handle 5, the right end of the push rod 4 is provided with a second handle 6, the second handle 6 is located on the right side of the first handle 5...

Embodiment 3

[0022] A kind of auxiliary sand dressing equipment for standing long jump, such as Figure 1-3 As shown, it includes a first bearing seat 2, a rotating shaft 3, a push rod 4, a first handle 5, a second handle 6, a mounting frame 7, a mounting plate 8, an arc block 9, a tapered block 10, and a second bearing block 12 , stirring wheel 13, thrust bearing 14, patterned tire 15, first round bar 16, L-shaped pole 17, first guide sleeve 18, first guide bar 19, arc frame 20, first arc bar 21, the first Two guide sleeves 22, slide bar 23, T-bar 24, first spring 25, connecting rod 26 and block 27, the first bearing seat 2 is installed on the ground 1, and the rotating shaft 3 is installed on the first bearing seat 2, the rotating shaft 3 The upper part is connected with a push rod 4, the right part of the push rod 4 is provided with a first handle 5, the right end of the push rod 4 is provided with a second handle 6, the second handle 6 is located on the right side of the first handle 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com