A method for demulsifying oil-in-water emulsions

An oil-in-water type, emulsion technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., to achieve the effect of rapid demulsification and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

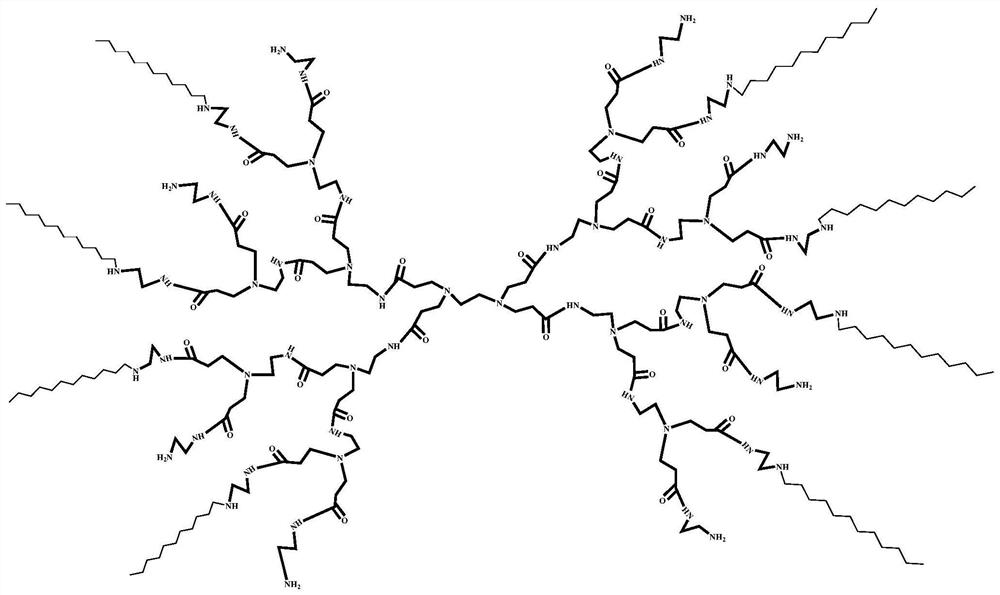

[0031] Embodiment 1: Amphiphilic hyperbranched polyamide amine modification (HPAMAM-am-C 12 )preparation

[0032] Dissolve 3g of HPAMAM in 20mL of methanol, inject a small amount of glacial acetic acid, stir and mix, then add 3.65mL of lauric aldehyde, and react at room temperature for 0.5h. Weighing 3.45g of sodium triacetoxyborohydride (STAB) was added to the reaction system, and reacted for 12 hours at room temperature to obtain a crude product with a high degree of polymerization; subsequently, the crude product was concentrated and cooled to room temperature and then extracted three times with dichloromethane, spin Steam to get HPAMAM-am-C 12 .

[0033] Amphiphilic hyperbranched polyamidoamine (HPAMAM-am-C 12 ) structure diagram, such as figure 1 As shown, it should be noted that since the hyperbranched structure is variable and complex, the structure shown is only an example.

Embodiment 2~4

[0034] Embodiment 2~4: Amphiphilic hyperbranched polyamidoamine modification (HPAMAM-am-C 12 )preparation

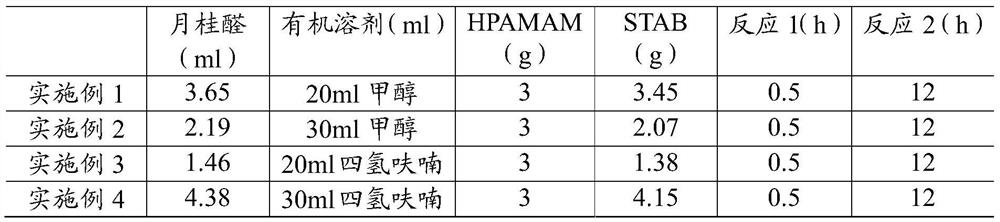

[0035] With reference to Example 1, amphiphilic hyperbranched polyamidoamine modified product is prepared, and the specific process parameters are as shown in table 1, and the amphiphilic hyperbranched polyamidoamine modified product (HPAMAM-am-C 12 ).

[0036] Table 1: Comparison of preparation process parameters in Examples 1 to 4

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com