Adjustable automatic medicine smashing device

An adjustable and automatic technology, used in grain processing and other directions, can solve the problems of inability to adjust the position of the mashing tank, incomplete mashing, and large labor, so as to reduce the mashing time, mash quickly and evenly, and reduce labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

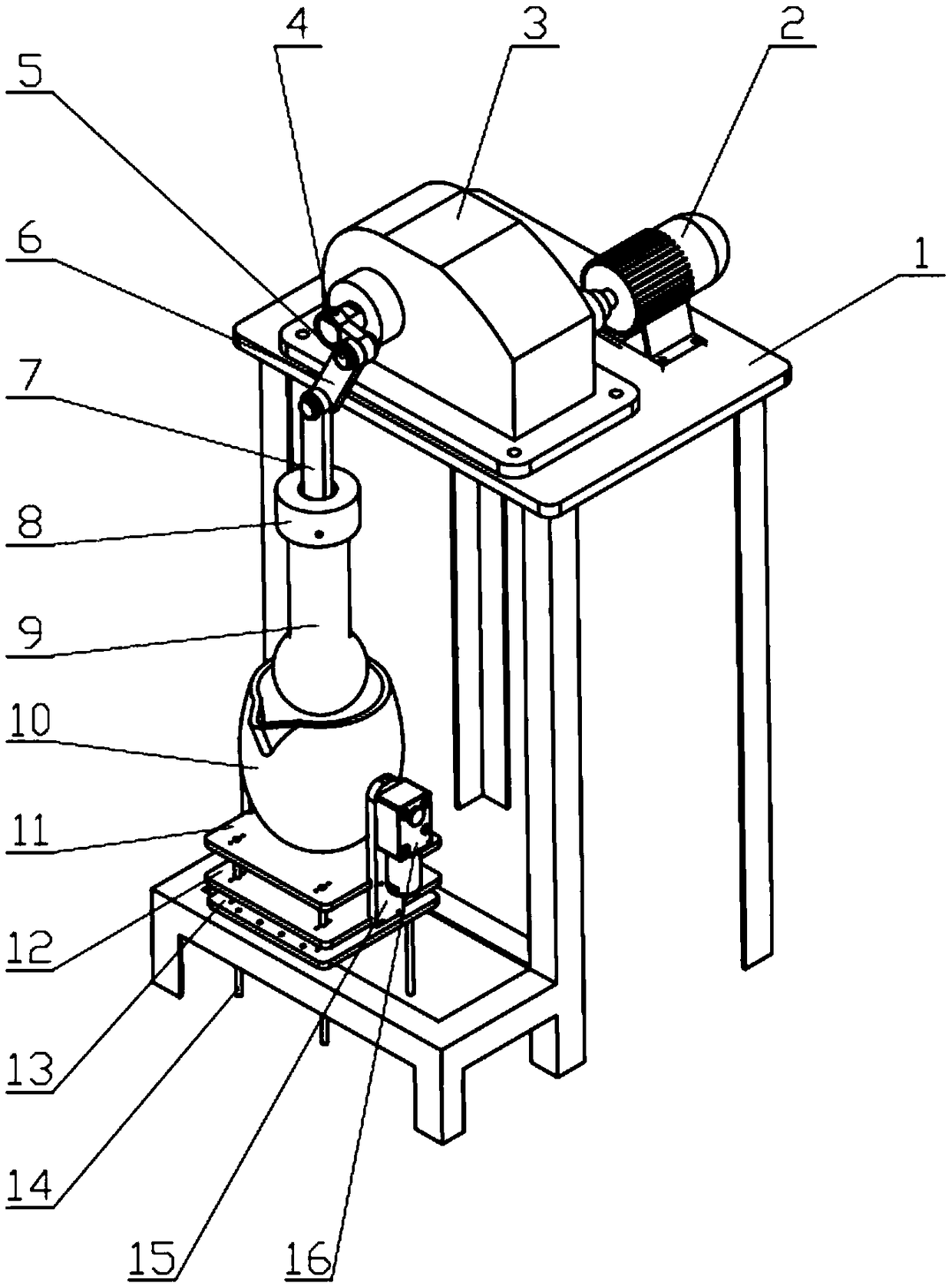

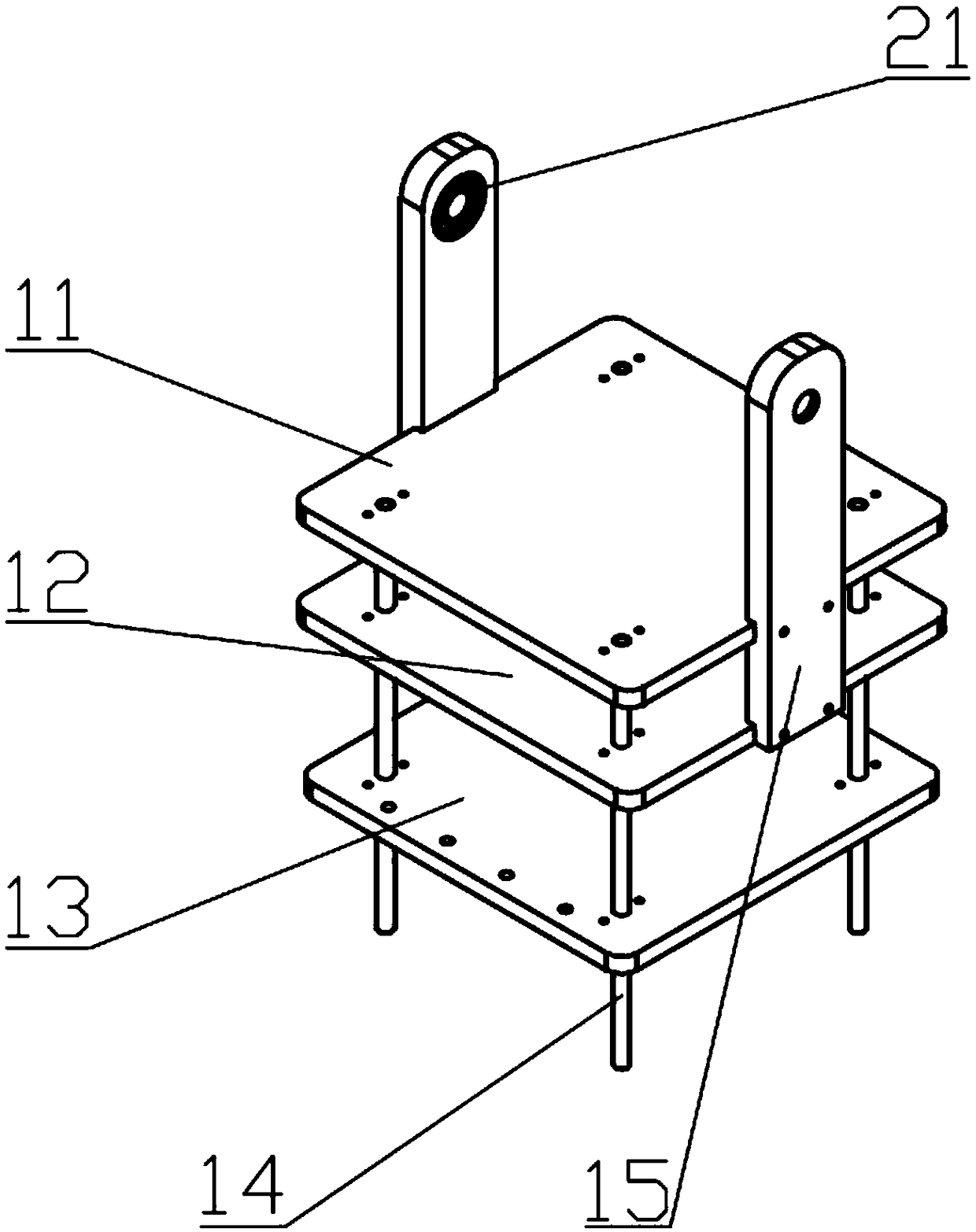

[0025] like figure 1 An adjustable automatic medicine pounding device comprises a workbench 1, a motor 2, a reduction box 3, a crank connecting rod mechanism, a medicine pounding mechanism, a medicine tank 10, and a lifting platform mechanism. The motor 2 and the reduction box 3 are installed on the workbench 1, the rotating shaft of the motor 2 is connected to the power input end of the reduction box 3, and the power output end of the reduction box 3 is connected to one end of the crank linkage mechanism. The opposite end is connected to the medicine pounding mechanism, and the medicine tank 10 is arranged on the medicine tank fixing frame 11 , and one end of the medicine pounding mechanism is located in the medicine tank 10 . The setting of the reduction box 3 is used to reduce the output speed of the output end and increase the torque of the power output end, so as to achieve more efficient ramming.

[0026] Wherein, the crank-link mechanism includes a crank 4, a pin 5, an...

Embodiment 2

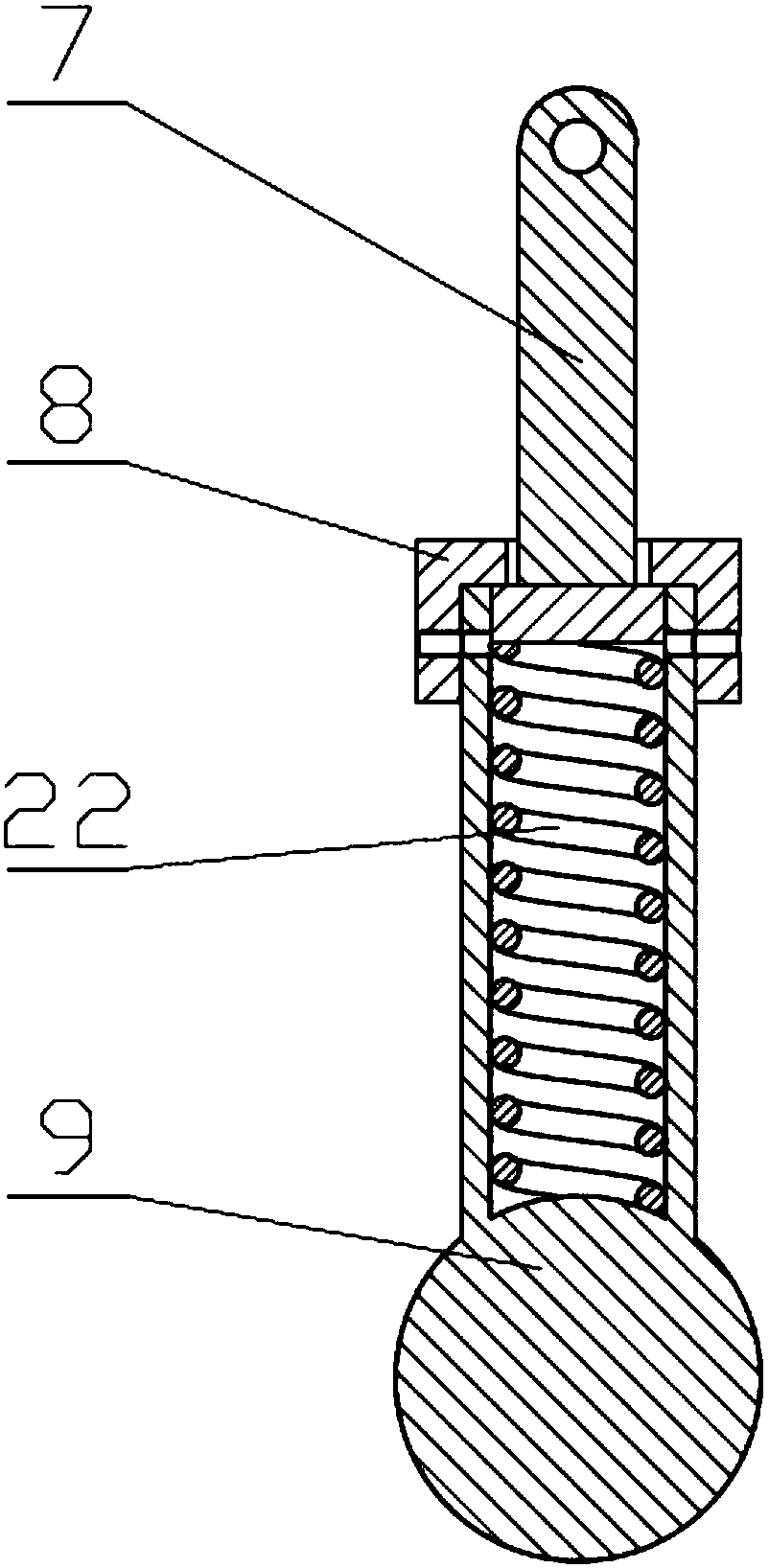

[0034]As shown in Embodiment 1, the only difference is that the bottom of the ramming rod 9 is provided with a threaded structure, which can effectively increase the friction between the ramming rod 9 and the medicine, making the ramming more sufficient. And in order to better fix the lifting platform mechanism, a storage surface is provided on the outer side of the two adjacent table legs of the workbench 1, and the lifting platform mechanism passes the screw on the storage surface.

Embodiment 3

[0036] Usually when pounding medicine, due to the opaqueness of the medicine tank, it is impossible to judge whether the medicine is pounded sufficiently. Therefore, the medicine tank 10 can be made of a transparent material, so that the staff can observe the state of the medicine in real time when pounding medicine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com