Automatic despooling and wire cutting device

A kind of equipment and automatic technology, applied in the field of automatic wire pay-off and trimming equipment, can solve the problems of difficult control of wire length and low efficiency, and achieve the effect of high-efficiency and high-precision automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

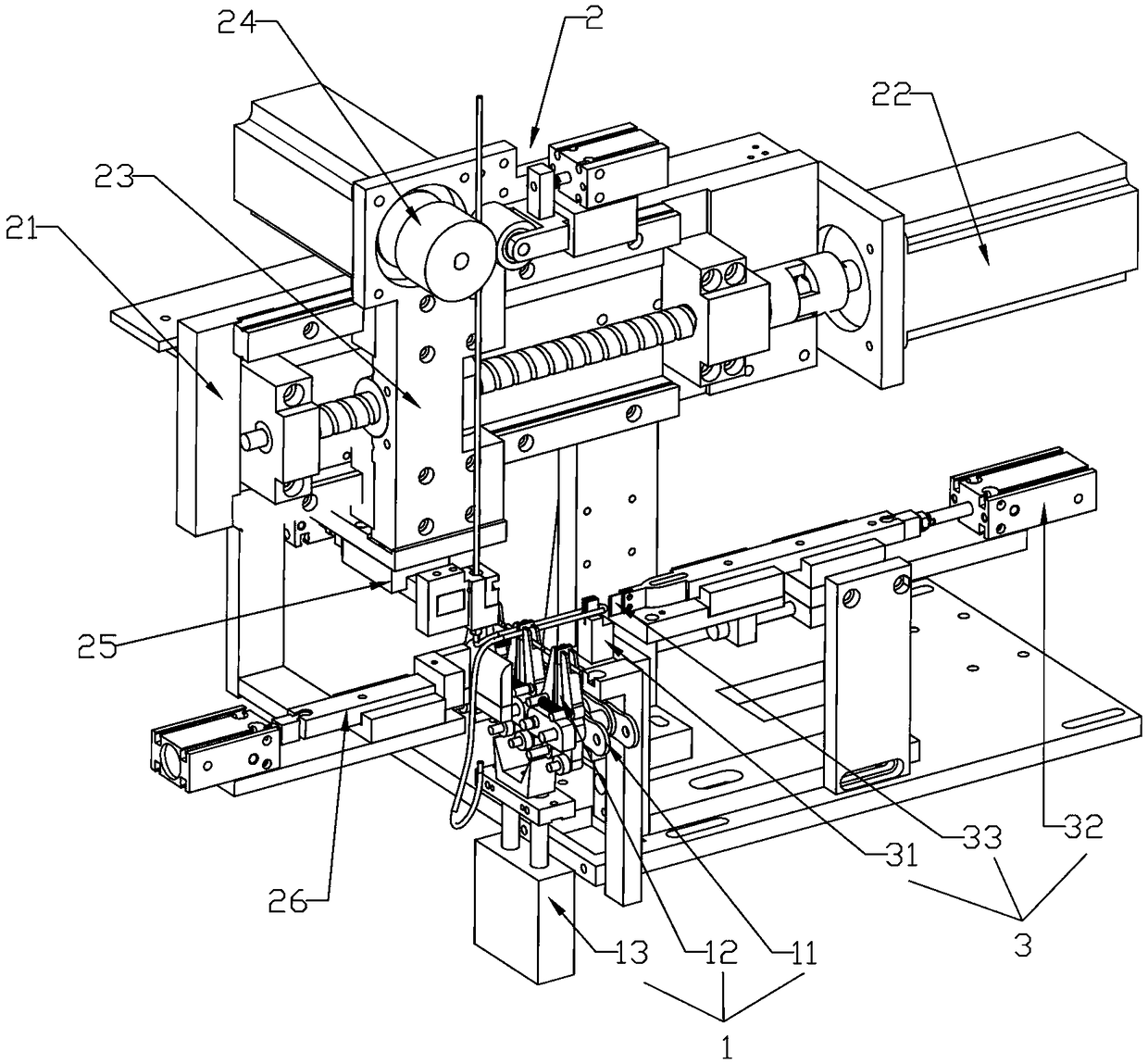

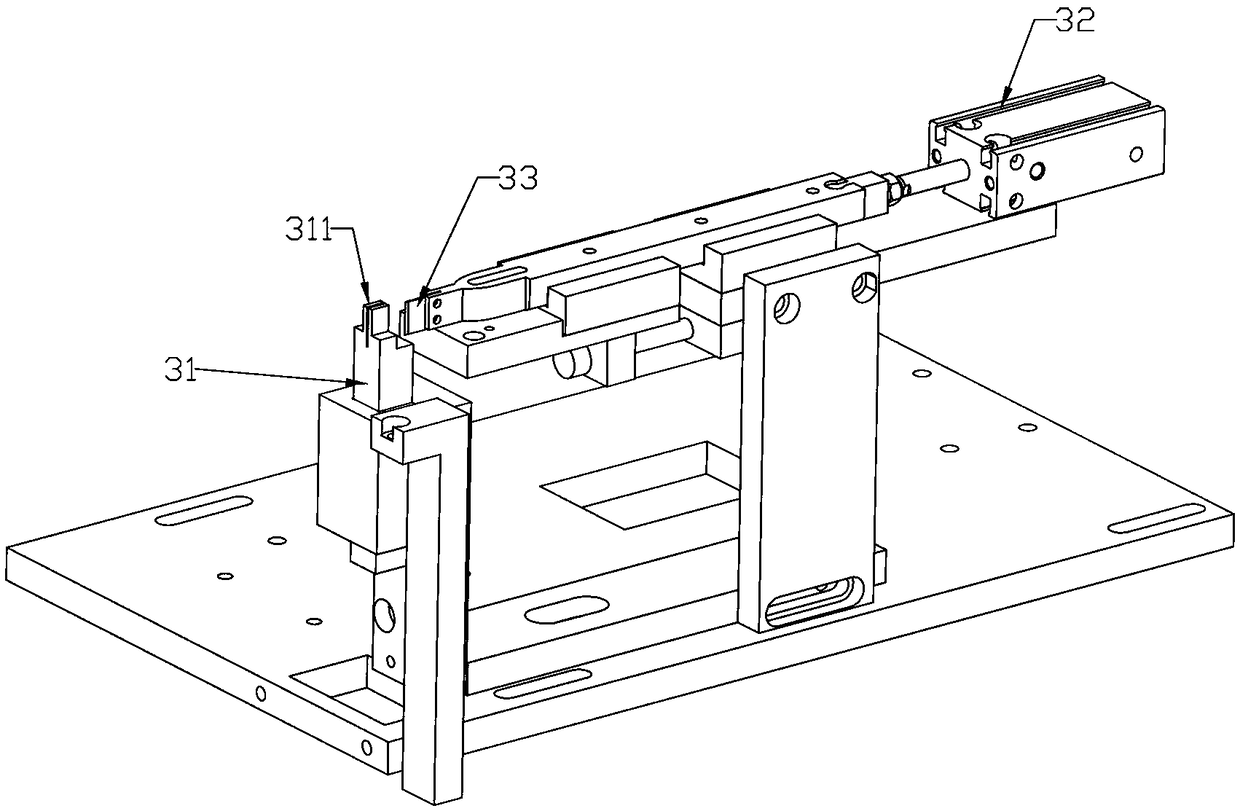

[0022] Such as Figure 1-6 As shown, an automatic wire unwinding and trimming device includes a clamping and conveying module 1, a wire feeding module 2 and a wire cutting module 3;

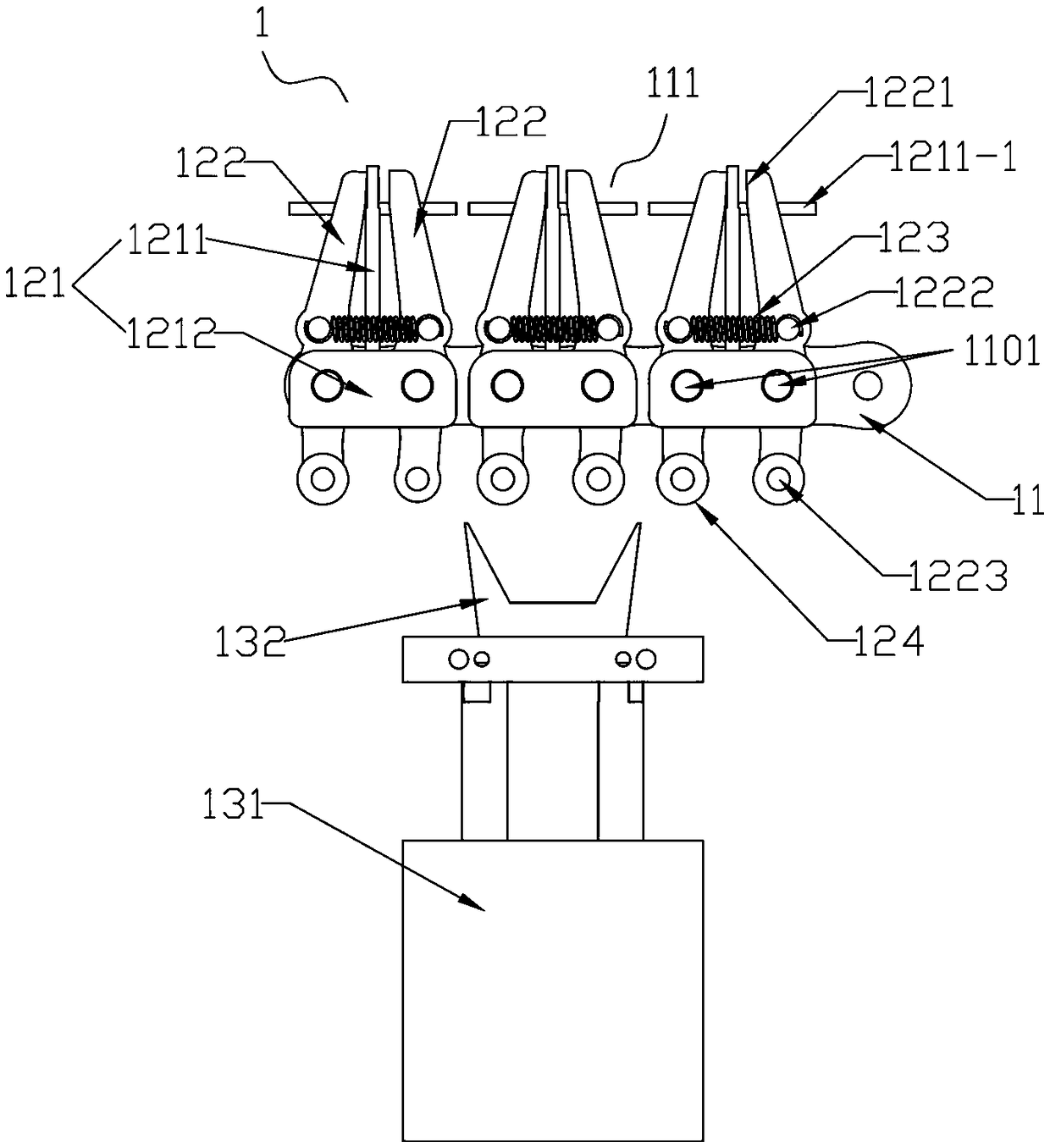

[0023] The clamping conveying module 1 includes a conveyor belt 11 transported from back to front, several clamping devices 12 uniformly installed on the conveyor belt 11 and a control device 13; the conveyor belt 11 has a trimmer Work station 111; the clamping device 12 includes a clamping plate 121 installed on the conveyor belt 11, clamps 122 connected to the front and rear sides of the clamping plate 121, and an elastic element 123 installed between the two clamping clamps 122; the clamping The upper end of the head 122 has a clamping surface 1221; the elastic element 123 tightens the clamping head 122 to press the clamping surface 1221 on the upper end of the clamping head 122 against th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com