Multifunctional adjustable nanometer heat source heating printing roller

A printing cylinder and adjustable technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of lack of oil inlet pipeline fixing device, inconvenient measurement of printing cylinder oil temperature, lack of printing typesetting fixing structure, etc. The effect of ensuring tightness, protecting safety, and ensuring the accuracy of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

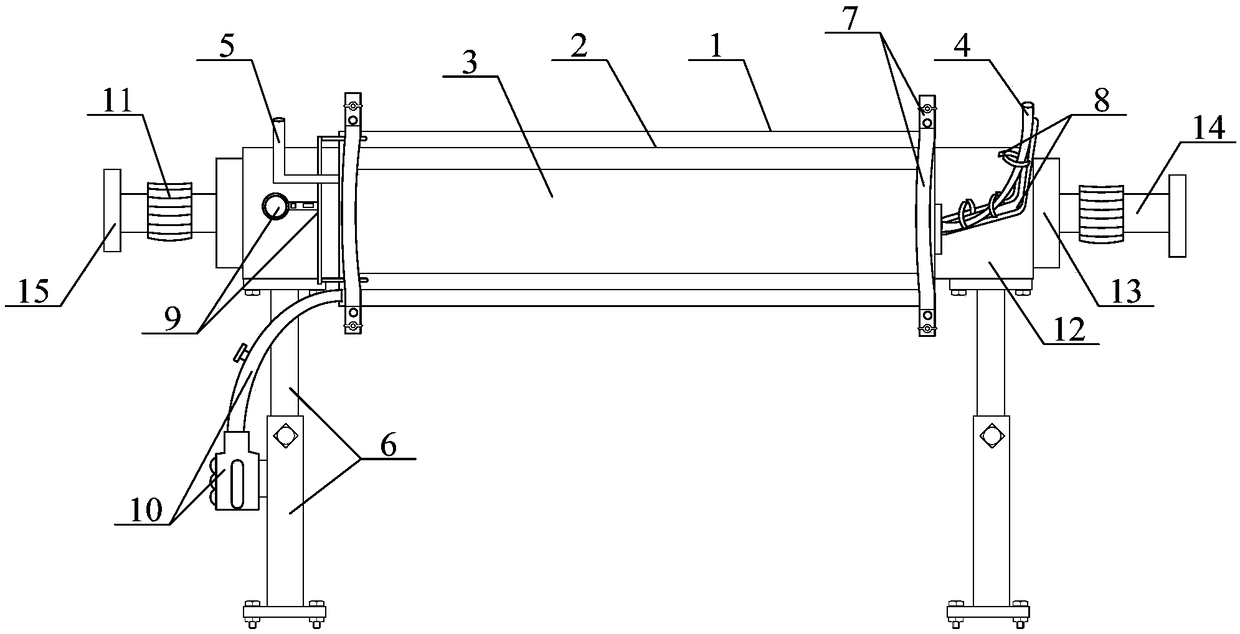

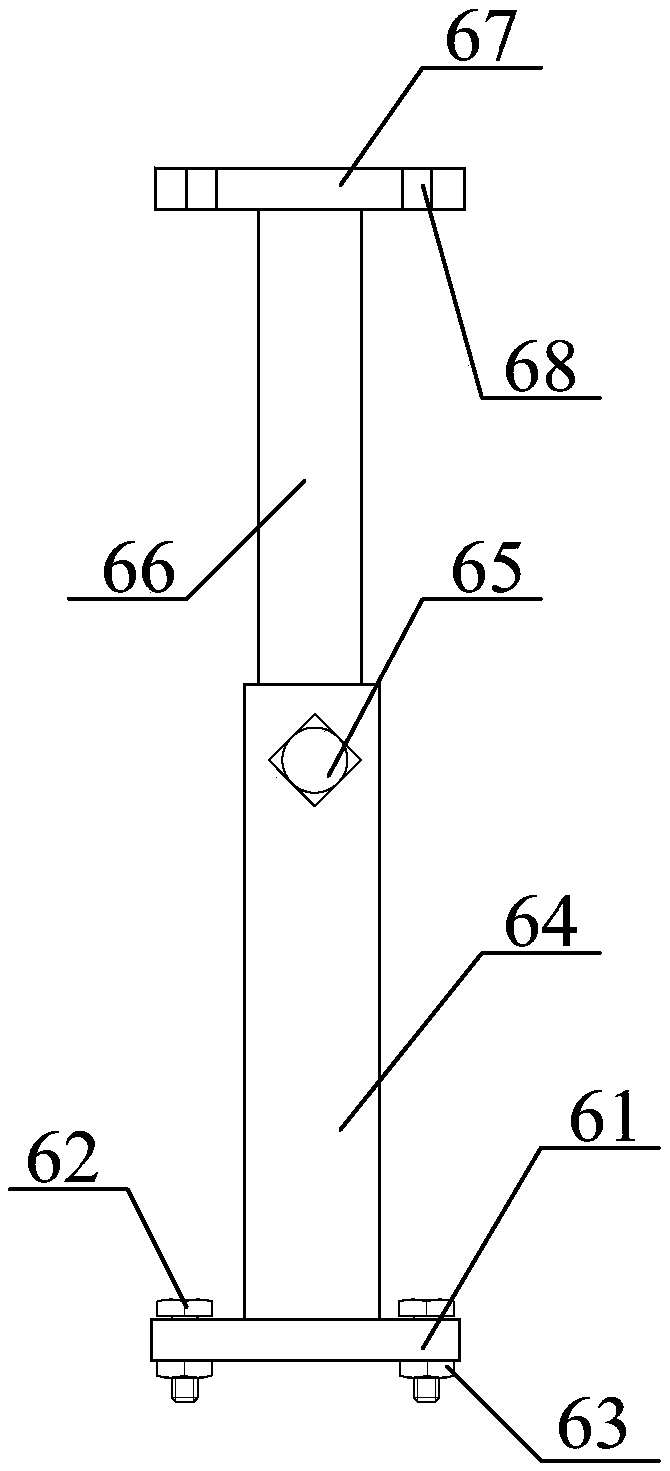

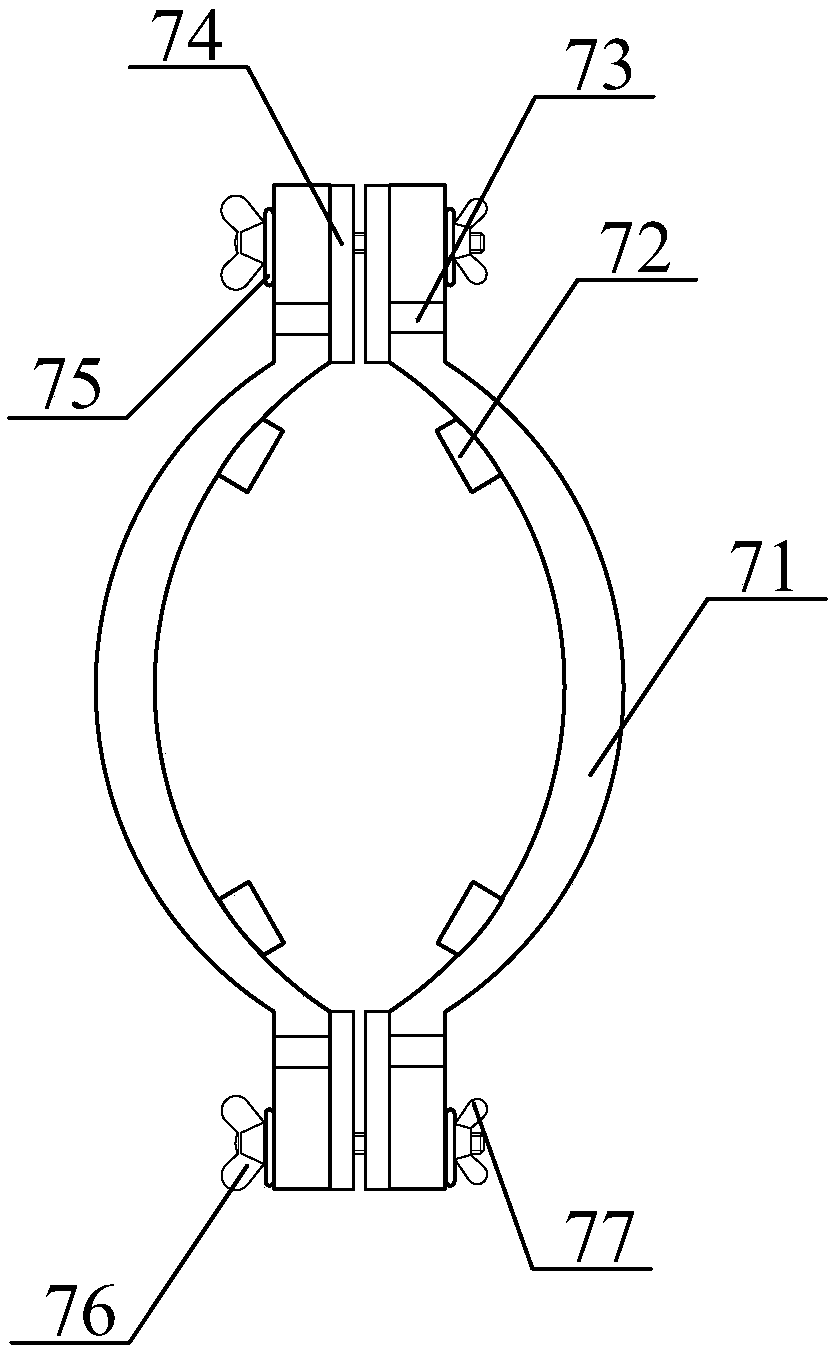

[0041] as attached figure 1 To attach figure 2 As shown, the present invention provides a multifunctional and adjustable nano-heat source heating printing cylinder, including a printing outer cylinder 1, a heating inner cylinder 2, a nano-heating layer 3, a heating oil inlet pipe 4, a heating oil outlet pipe 5, and adjustable support Rod structure 6, printing fixed hoop structure 7, heating oil pipe fixing seat structure 8, inner and outer cylinder temperature detection probe structure 9, heating oil sampling pipe structure 10, connecting gear 11, outer connecting end cover 12, stepped shaft 13, through core Shaft 14 and flange 15, the printing outer cylinder 1 is welded on the outer surface of the heating inner cylinder 2; the nanometer heating layer 3 is applied on the inner surface of the heating inner cylinder 2; the heating oil inlet pipe 4 Installed inside the heating oil pipe fixing seat structure 8; the heating oil inlet pipe 4 is threaded to the middle position on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com