The Method of Stiffening Beams for Construction of Large-span Suspension Bridges by Cable Hanging

A suspension bridge and long-span technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as limited lifting capacity of cable cranes, and achieve the effect of safe erection construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

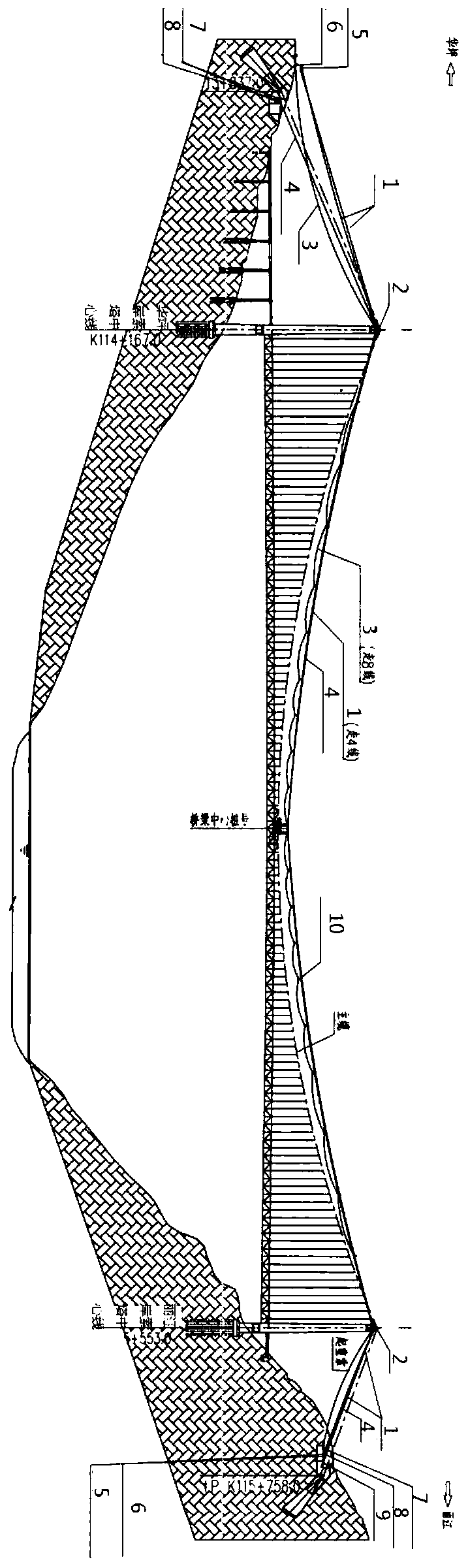

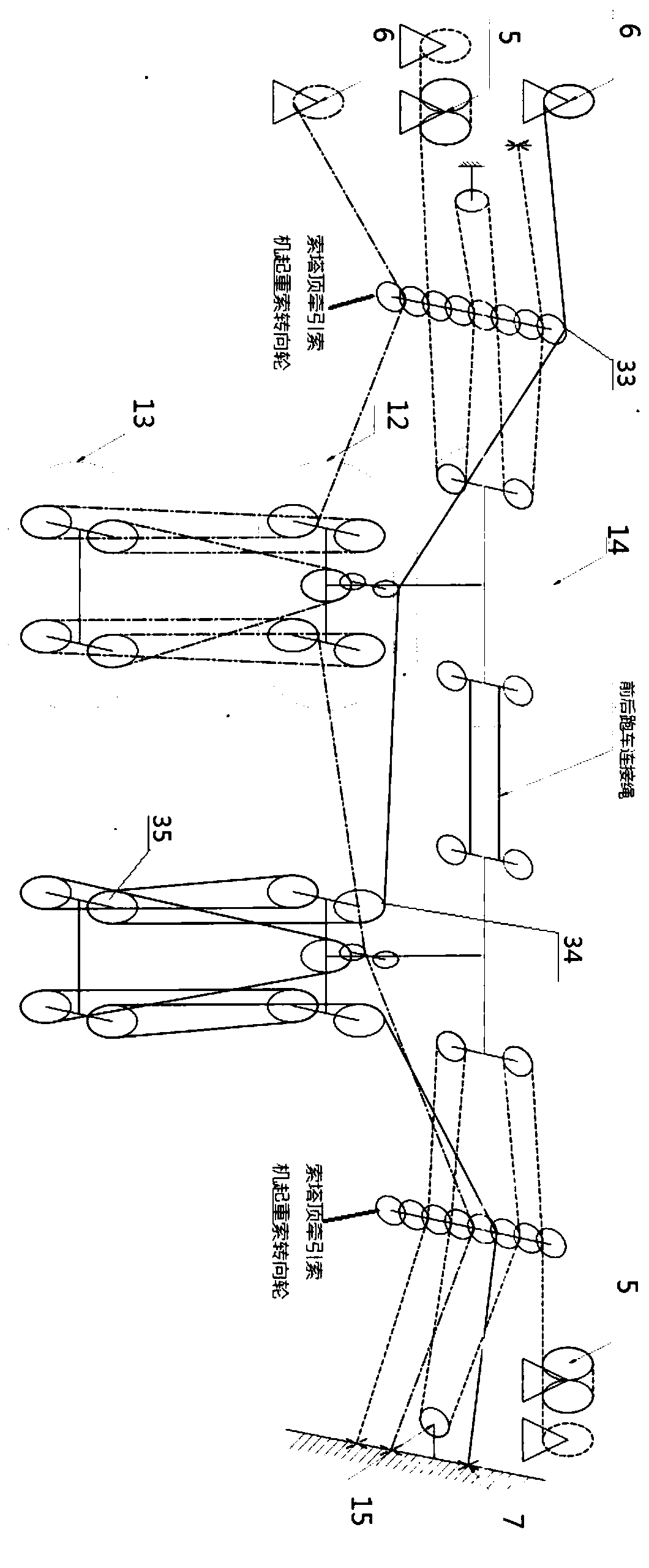

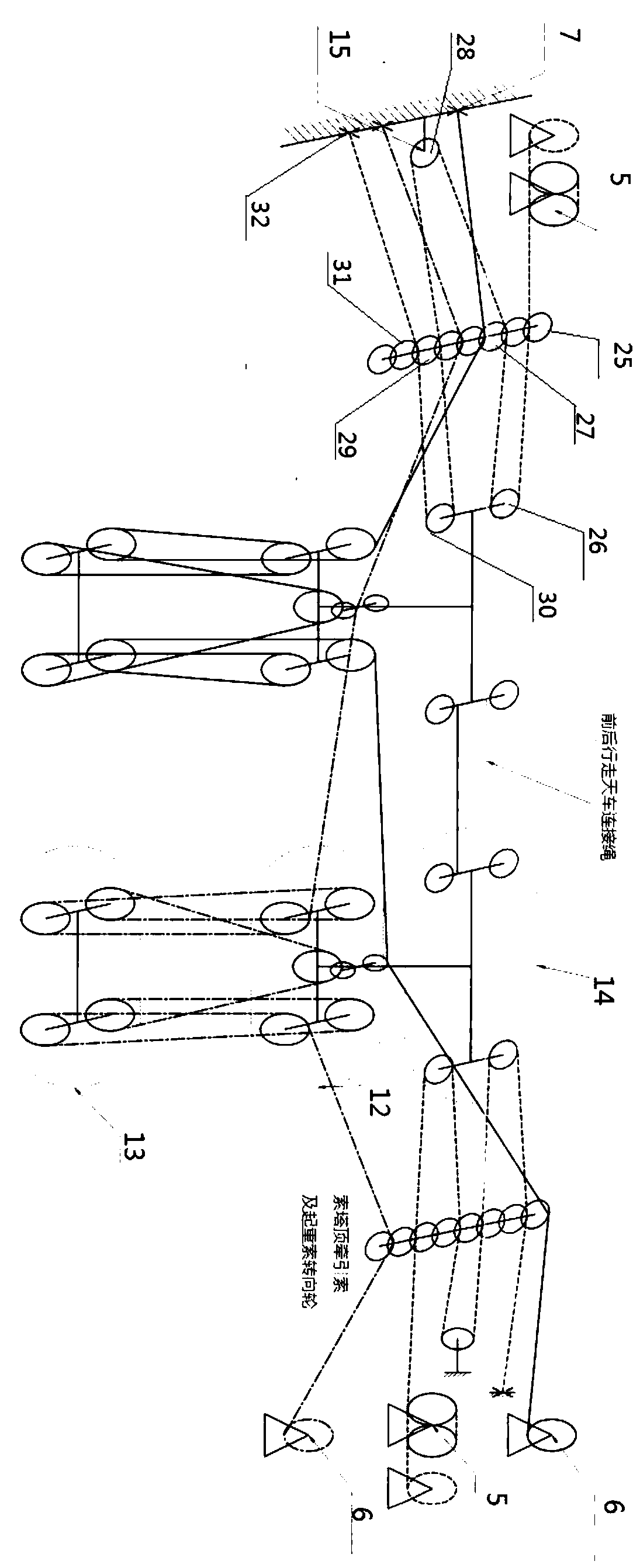

[0057] This embodiment is applied to the cable crane construction of Jin'an Jinsha River Bridge in Yunnan. The main bridge of Jin'an Jinsha River Bridge is a 330m+1386m+205m double-tower single-span steel truss suspension bridge. A steel truss assembly site is set up on the front side of the main tower, and the steel truss beams are transported to the installation location by cable equipment. The cable crane system adopts the double-tower and three-span scheme: the main cable (load-bearing cable) is arranged in two sets of cables, and the distance between the centers of the two sets of cables is 13.5m. On the foundation of anchor loose cable saddle, two groups of cables are arranged symmetrically with the centerline of the bridge. The maximum hoisting weight of the cable crane is 220t. When the maximum hoisting weight is at the mid-span, the maximum mid-span sag is 115.5m, and the vertical-span ratio is 1 / 11. The 20m (clear distance) range of the Lisuo saddle is the blind are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com