Underground coal mine hydraulic oriented roof cutting equipment and construction method thereof

A hydraulic and coal mine technology, applied in coal mine underground hydraulic directional roof cutting equipment and its construction field, can solve problems such as difficult support, large blast shock wave disturbance, complicated procedures, etc., achieve low operation and maintenance costs, and few use restrictions , The effect of simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

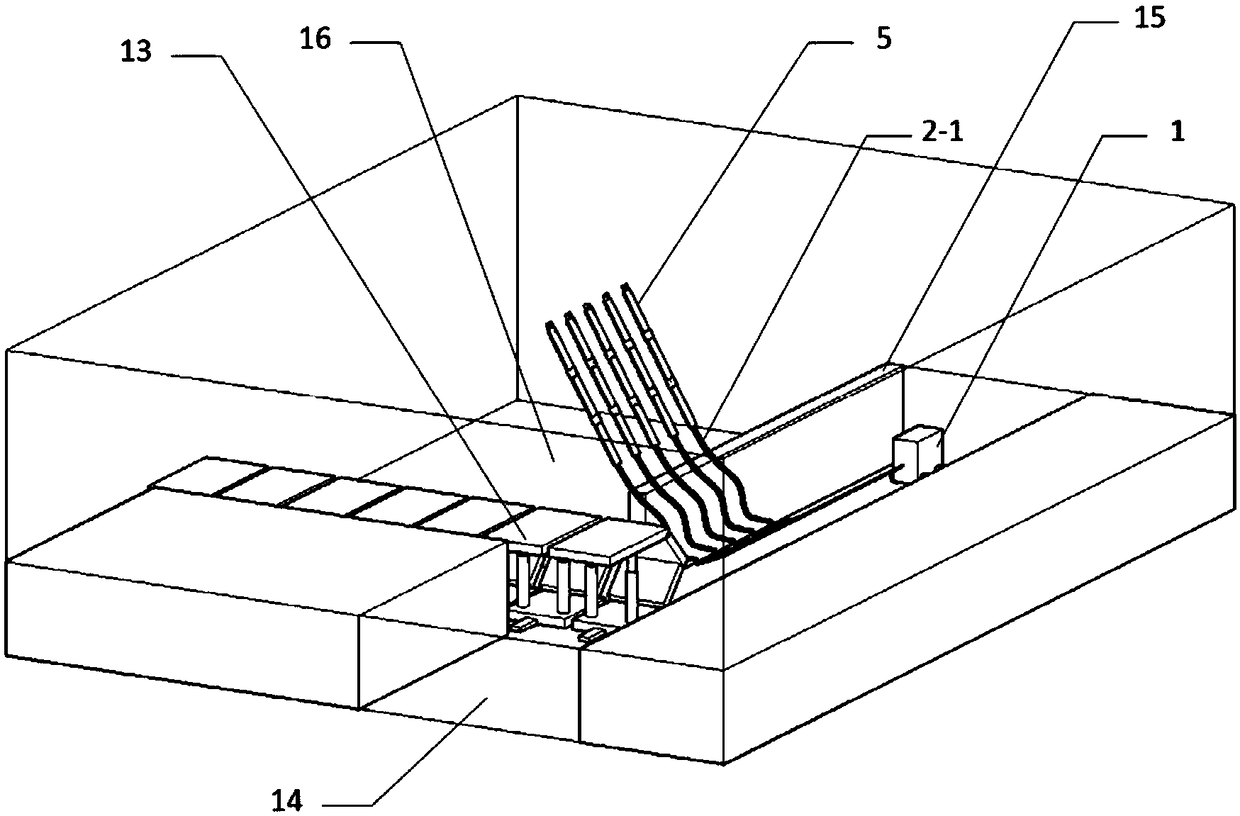

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] Coal mine A adopts gob-side entry retaining technology, and concrete walls are used as roadside support. Coal mine A mines 8 coals, with an average thickness of 3.2m, a near-horizontal coal seam, and a buried depth of about 700m. It belongs to a high-gas mine. Along the trough, they are respectively the transport trough and the return air trough, and gob-side entry is carried out for the transport trough. Roof cutting technology is used to reduce the pressure of gob-side entry retention. The thickness of the wall beside the lane is 1.0m, and the height is 3.2m.

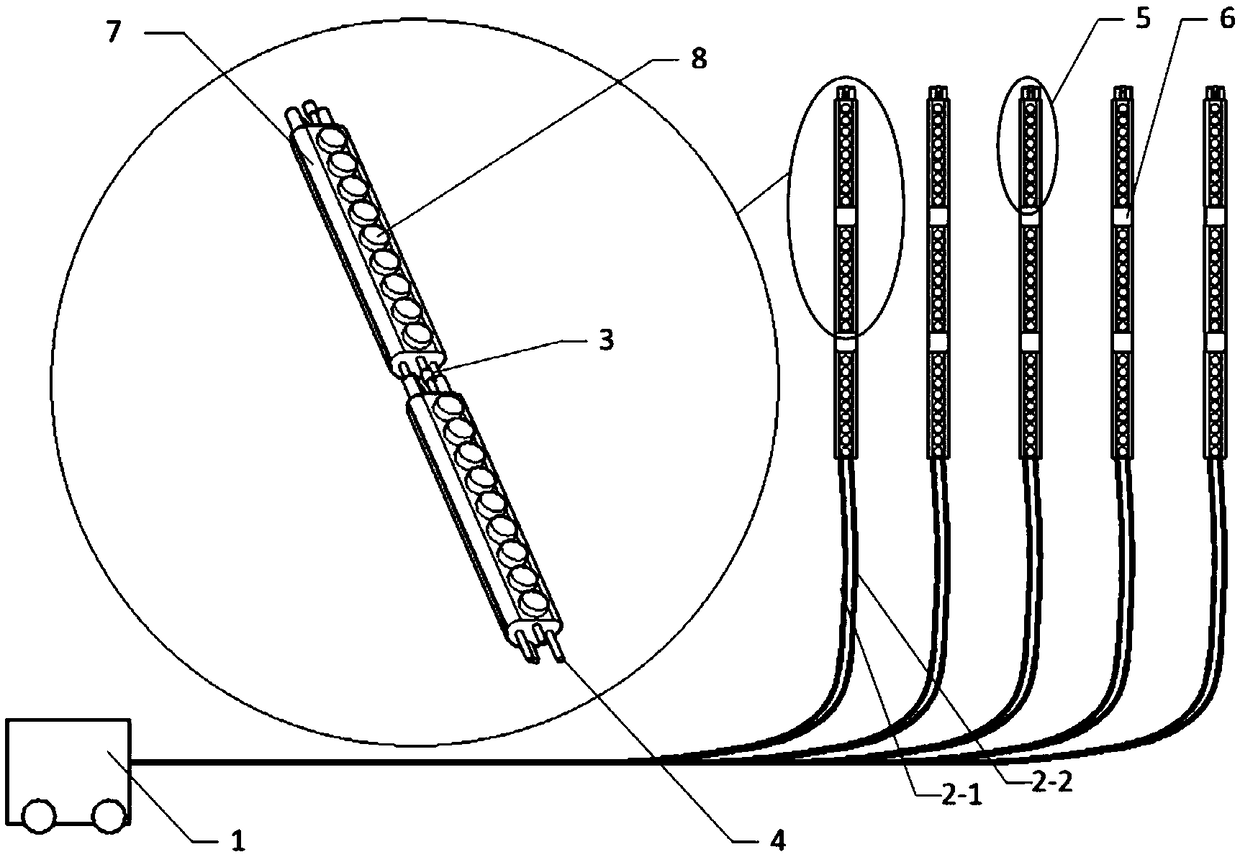

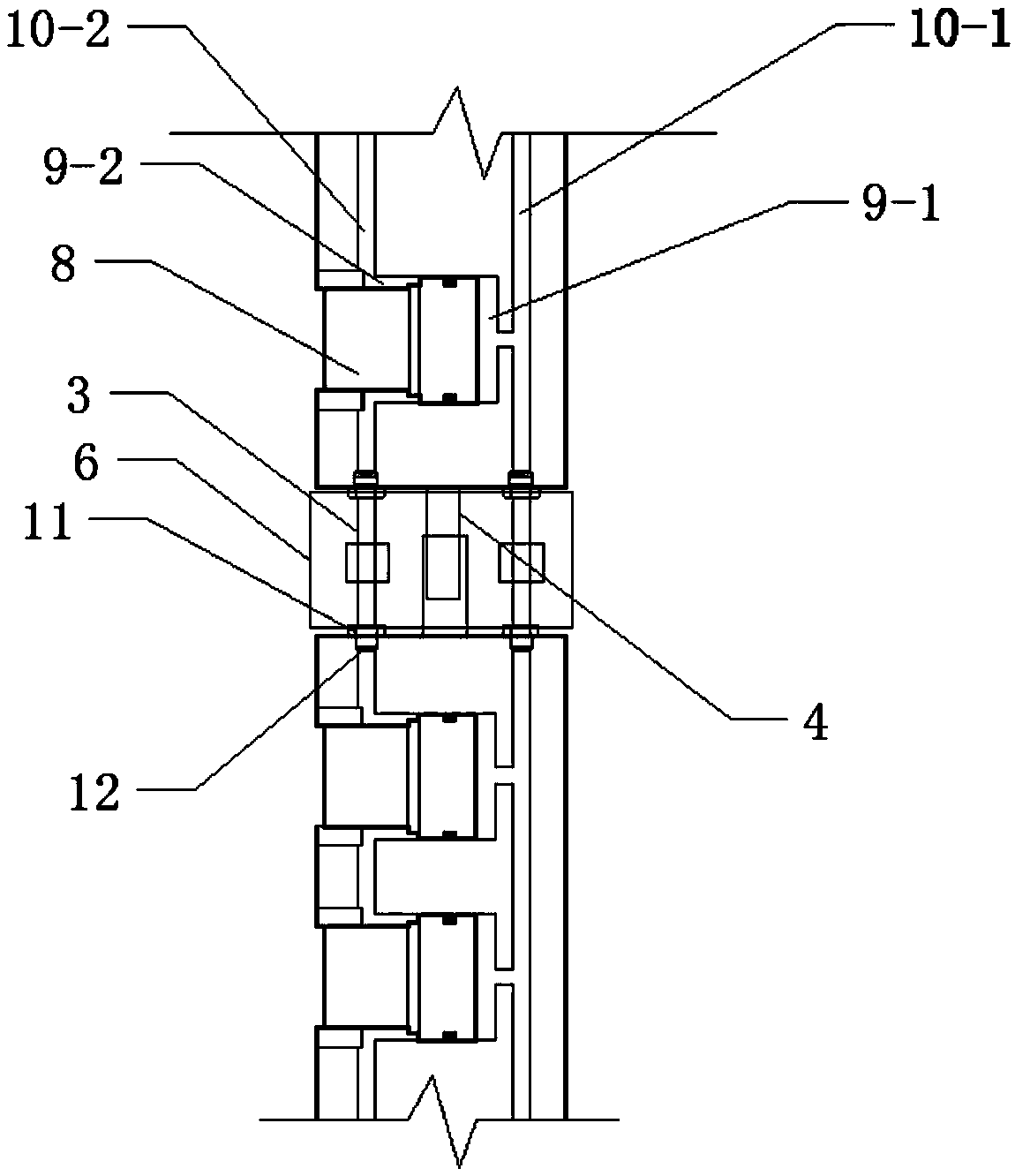

[0032] Such as Figure 1 to Figure 4 As shown, the coal mine underground hydraulic directional roof cutting equipment provided by the present invention is composed of 1 explosion-proof pump station 1, 5 liquid inlet long pipes 2-1, 5 liquid return long pipes 2-2 and N side thrusters, Explosion-proof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com