Novel sliding main shaft structure

A main shaft and a new type of technology, used in machines/engines, liquid fuel engines, liquid variable capacity machines, etc., can solve the problems of general tensile strength, complex overall structure, and inflexible use, and achieve high tensile strength and connection. The effect of convenient molding, novel and practical overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

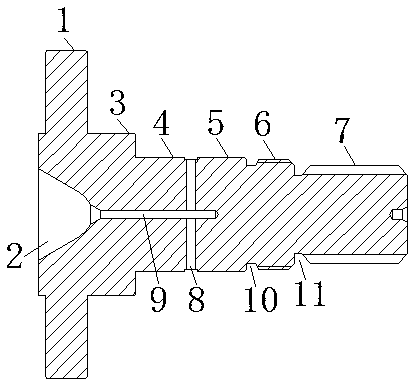

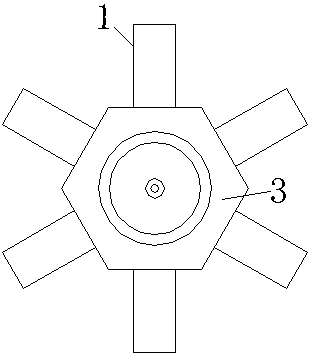

[0014] Such as figure 1 and figure 2 As shown, a novel sliding main shaft structure according to the present invention includes a long axis body and six sliding columns 1 evenly arranged at one end of the long axis body, and the sliding columns 1 are vertically arranged with the long axis body, and the sliding columns A positioning ball socket 2 is provided in the middle of the end face of the long shaft body on one side. The long shaft body includes a sliding column connection section 3, a bearing connection section I4, a bearing connection section II5, a thread section 6 and a spline tooth section 7. The cross-section of the connecting section 3 of the sliding column is a regular hexagon, the cross-sections of the bearing connecting section I4, the bearing connecting section II5, the threaded section 6 and the spline tooth section 7 are all circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com