Novel double-valve pneumatic stop valve

A pneumatic globe valve and valve technology, applied in valve details, valve device, valve shell structure, etc., can solve the problems affecting production efficiency and production benefits, difficult to confirm opening and closing, laborious operation, etc., to achieve simplified structure and low operation Time-saving and labor-saving effects of reducing work accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

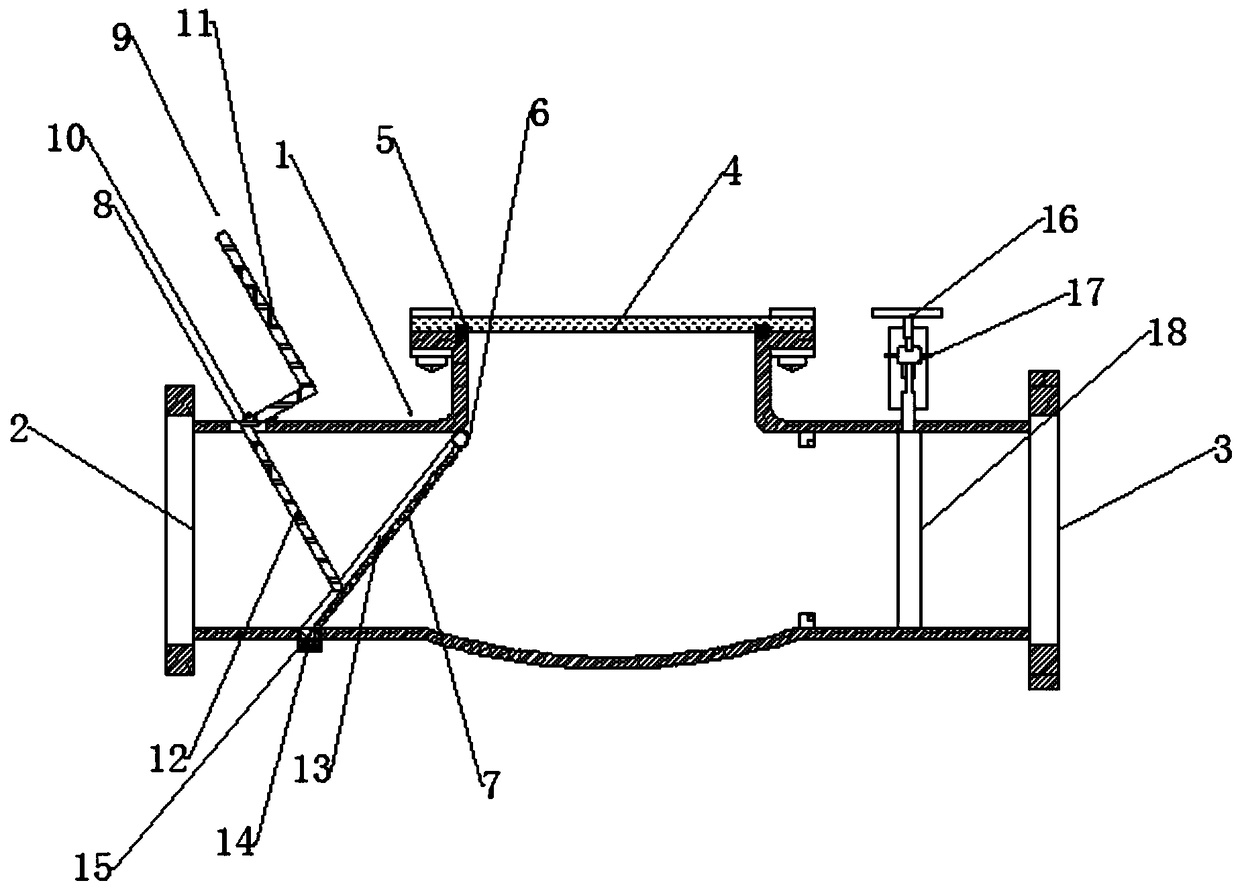

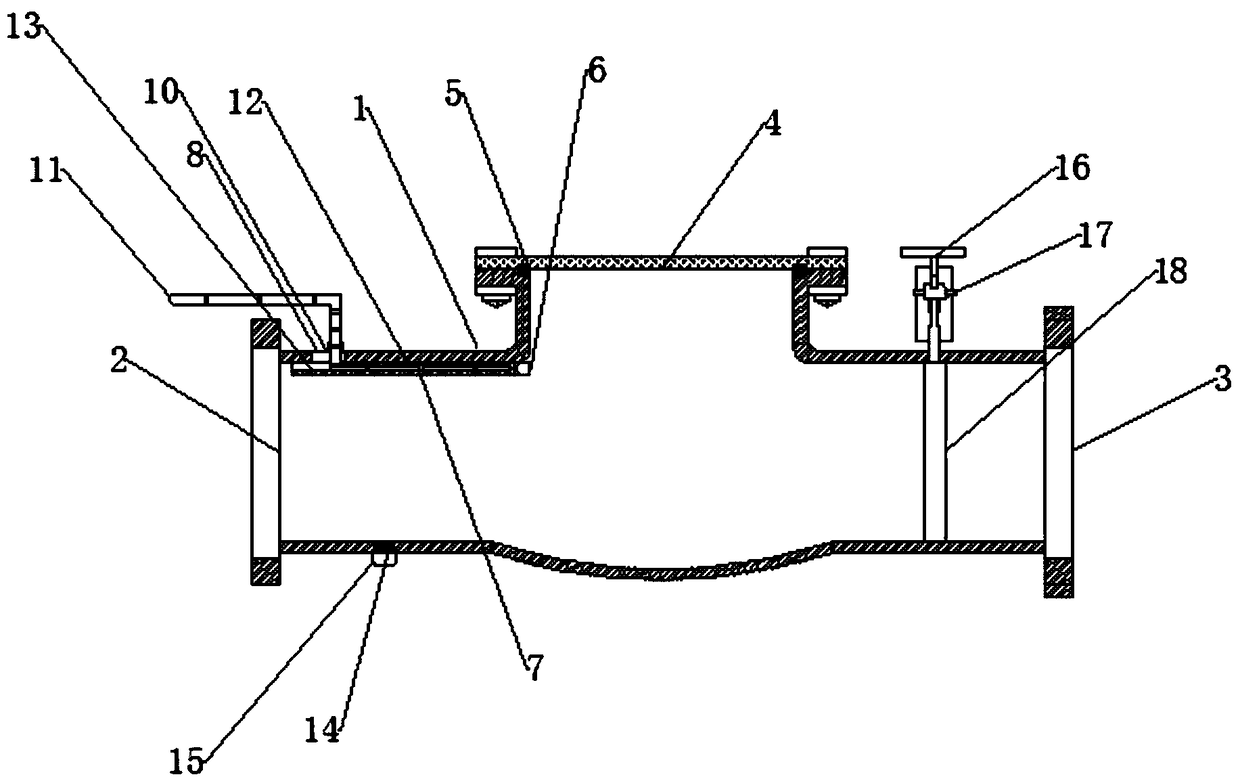

[0026] A new double-valve pneumatic globe valve, comprising a valve body 1, the left side of the valve body 1 is fixedly connected with an inlet 2, the right side of the valve body 1 is fixedly connected with an outlet 3, and the top of the valve body 1 passes through Bolts are fixedly connected with a valve cover 4, and a first sealing ring 5 is arranged between the valve body 1 and the valve cover 4; the inner wall of the inner cavity of the valve body 1 is provided with an ejection type first valve assembly near the inlet 2, and the A second valve assembly is provided near the outlet 3 on the inner wall of the valve body 1 .

[0027] Firstly, the double-valve pneumatic shut-off valve of the present invention is fixedly connected to the installed pipeline. When the double-valve pneumatic shut-off valve is opened, the first valve assembly and the second valve assembly are opened, and the material passes through; when the double-valve pneumatic shut-off valve When the valve is...

Embodiment 2

[0029] Based on Embodiment 1, the first valve assembly includes a spring hinge shaft 6 fixedly connected to the inner wall of the valve body 1, a partition plate 7 fixedly attached to the inner wall of the valve body 1 through the spring hinge shaft 6, and the valve body 1. A bracket component that is flexibly connected to the outer wall. The partition 7 is fixed on the inner wall of the valve body 1 through the spring hinge shaft 6. The spring hinge shaft 6 makes the partition 7 always adhere to the inner wall of the valve body 1 without external force; the bracket assembly can be used to push the partition 7 to the partition The side opposite to the inner wall side of the valve body 1 where the plate 7 is located.

Embodiment 3

[0031] Based on Embodiment 2, the bracket assembly includes a through hole 8 provided on the outer wall of the valve body 1 and a bent strut 9 passing through the through hole 8; a folded sealing sleeve 10 is provided at the through hole 8 . The strut 9 passes through the through hole 8, a part of the strut 9 is located inside the valve body 1, and the other part of the strut 9 is exposed to the outside of the valve body 1. The folded sealing sleeve 10 facilitates the position movement of the strut 9 during rotation and prevents the material Escape acts as a seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com