Composite paint grinding system

A compound and paint technology, applied in chemical instruments and methods, cleaning methods and appliances, grain processing, etc., can solve the problems of insufficient grinding and low grinding efficiency, and achieve corrosion prevention, strong fluidity, and increased contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

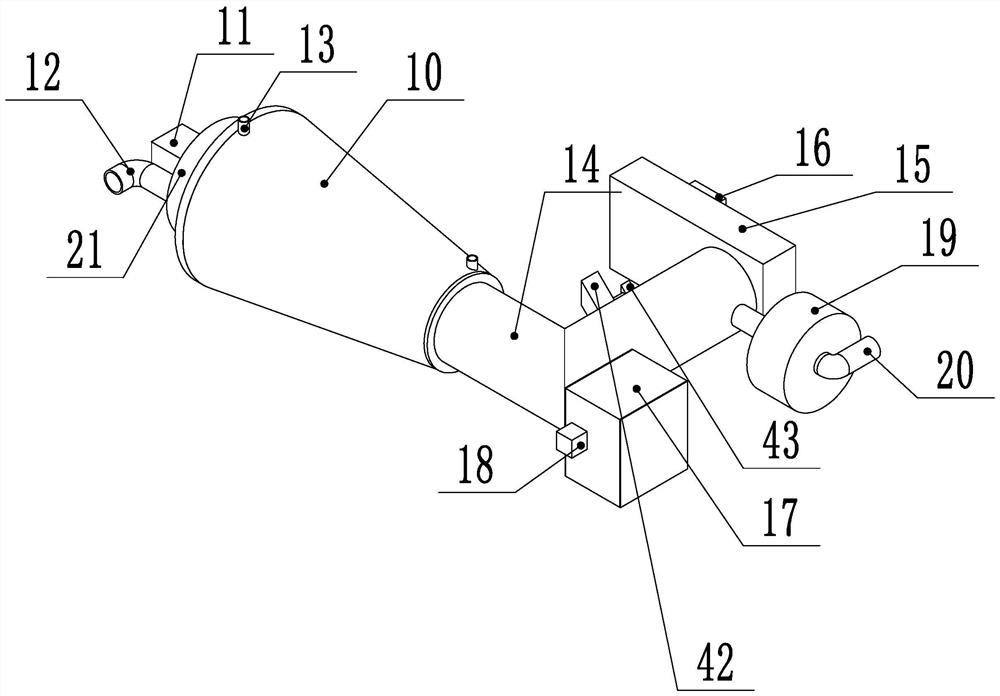

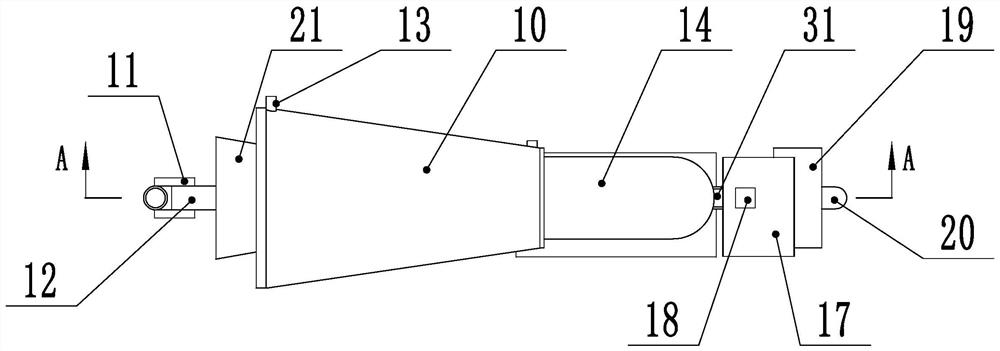

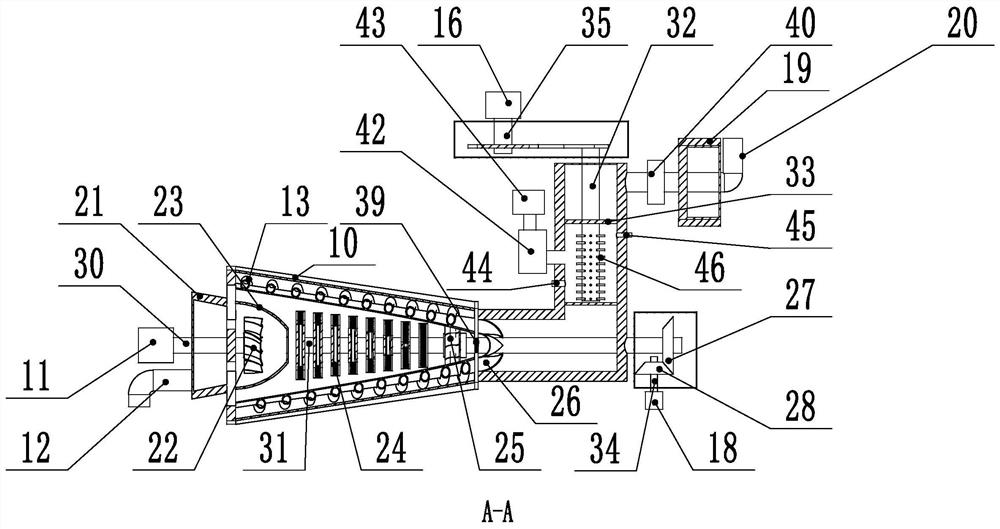

[0031] Such as figure 1 , image 3As shown, a compound paint grinding system includes a housing 10, a feed bin 21 is provided on the upper side of the housing 10, a cooling pipe 13 is provided inside the housing 10, a bead mill bin 29 is provided inside the housing 10, and a bead mill A first shaft 31 is provided for rotation in the bin 29, and a bead mill device is arranged on the first shaft 31. The bead mill device is used for preliminary grinding of the incoming paint. The bead mill bin 29 is provided with a vortex generating device, which is used for In order to enhance the fluidity of the incoming paint, a sanding tube 14 is provided on the front side of the housing 10, and a sanding device is arranged inside the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com