Determination method of arsenic and mercury content in plant samples and sample pretreatment method

A sample pretreatment and sample technology, which is applied in the field of arsenic, sample pretreatment, and mercury content determination in plant samples, can solve the problems of low reliability of determination results, and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a sample pretreatment method for determining the content of arsenic and mercury in plant samples, which includes:

[0046] a. Pretreatment step: After cleaning the plant samples collected in the field, dry them at 80° C., crush the dried plant samples and pass them through a 100-mesh nylon sieve for later use.

[0047]b. Digestion step: Dry the spare plant samples in an oven at 60°C for 2 hours, put them in a drying dish and weigh them after cooling. Accurately weigh 0.5g (accurate to 0.1mg) of the plant sample, place it in a digestion tube, add 8mL of concentrated nitric acid, tighten the lid of the digestion tube and place it in a microwave digestion apparatus, and digest the sample according to the digestion procedure in Table 1.

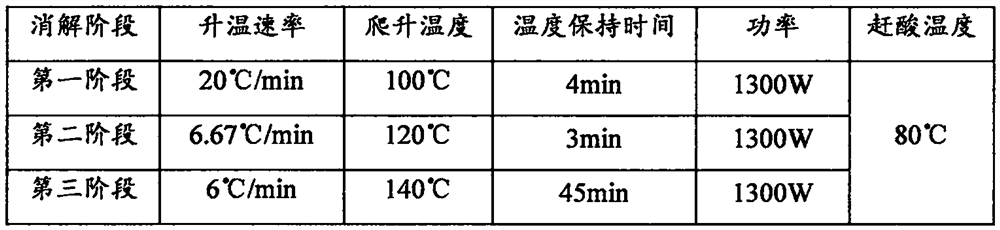

[0048] Table 1. Plant sample digestion procedure in Example 1

[0049] Digestion stage Heating rate Climb temperature temperature holding time power The first stage 10℃ / min 100℃ 5min 12...

Embodiment 2

[0052] This embodiment provides a sample pretreatment method for determining the content of arsenic and mercury in plant samples, which includes:

[0053] a. Pretreatment step: After cleaning the plant samples collected in the field, dry them at 75° C., crush the dried plant samples and pass them through an 80-mesh nylon sieve for later use.

[0054] b. Digestion step: Dry the spare plant samples in an oven at 55°C for 2.5 hours, put them in a drying dish and weigh them after cooling. Accurately weigh 1 g (accurate to 0.1 mg) of the plant sample, place it in a digestion tube, add 8 mL of concentrated nitric acid, tighten the lid of the digestion tube and place it in a microwave digestion apparatus, and digest the sample according to the digestion procedure in Table 2.

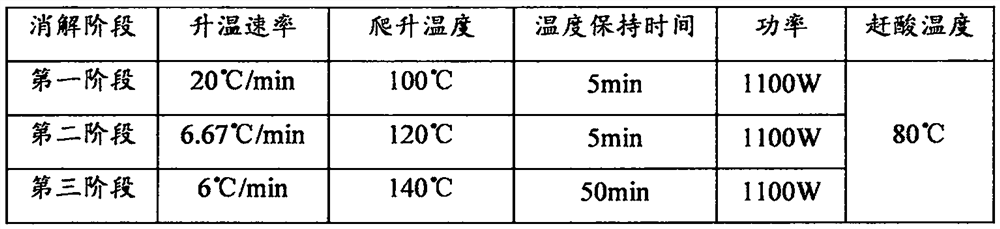

[0055] Table 2. Plant sample digestion procedure in Example 2

[0056] Digestion stage Heating rate Climb temperature temperature holding time power The first stage 22℃ / min 80℃ 4min ...

Embodiment 3

[0059] This embodiment provides a sample pretreatment method for determining the content of arsenic and mercury in plant samples, which includes:

[0060] a. Pretreatment step: After cleaning the plant samples collected in the field, dry them at 85° C., crush the dried plant samples and pass them through a 120-mesh nylon sieve for later use.

[0061] b. Digestion step: Dry the spare plant samples in an oven at 65°C for 1.5 hours, put them in a drying dish and weigh them after cooling. Accurately weigh 1 g (accurate to 0.1 mg) of the plant sample, place it in a digestion tube, add 8 mL of concentrated nitric acid, tighten the lid of the digestion tube and place it in a microwave digestion apparatus, and digest the sample according to the digestion procedure in Table 3.

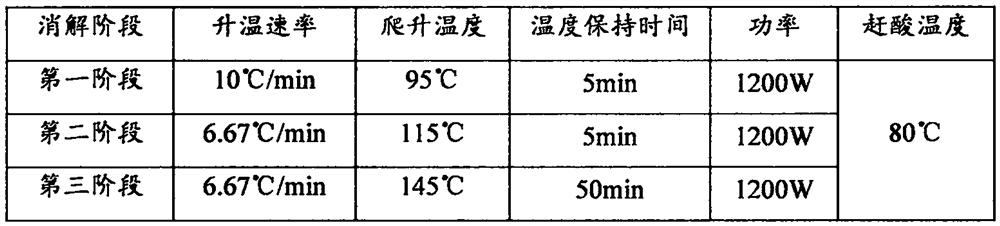

[0062] Table 3. Plant sample digestion procedure in Example 3

[0063] Digestion stage Heating rate Climb temperature temperature holding time power The first stage 18℃ / min 90℃ 3min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com