Surface quality detecting system and method for automobile covering parts

A technology for automotive panels and surface quality, applied in measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve problems such as low detection efficiency, increased production costs, and low accuracy, and achieve High accuracy, reduced production costs, and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

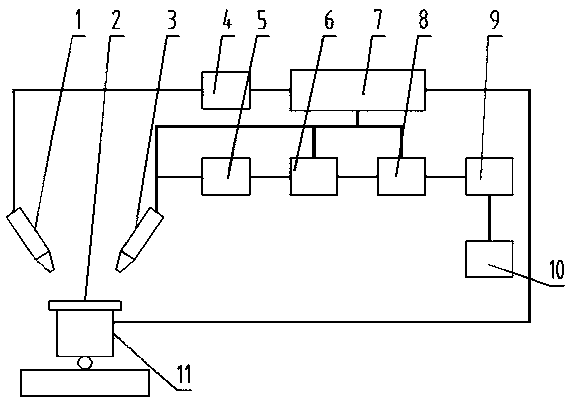

[0019] see figure 1 , a surface quality inspection system for automobile panels, comprising a CCD camera 3, a light source 1, a DSP signal processor 8, and a detection module 9, characterized in that: the CCD camera 3 and the light source 1 are symmetrically fixed on the inspection table 11 On the top, the signal output end of the CCD camera 3 is connected with the signal input end of the analog signal processor 5, and the output end of the analog signal processor 5 is input by the signal of the A / D conversion circuit 6 and the DSP signal processor 8 The signal output terminal of the DSP signal processor 8 is connected with the signal input terminal of the detection module 9, and the detection module 9 is composed of a rupture defect detection module, a scratch defect detection module, and an indentation defect detection module. The light source 1 is controlled by a light source controller 4 , and the light source controller 4 , A / D conversion circuit 6 , DSP signal processor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com