Electromagnetic lock working state detecting method

A technology of working state and detection method, applied in the direction of measuring electricity, measuring device, measuring electrical variable, etc., can solve the problem that it is difficult to obtain the working state of the electromagnetic lock, it is impossible to judge the reliable opening or locking of the friction plate type electromagnetic lock, and the performance is degraded. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

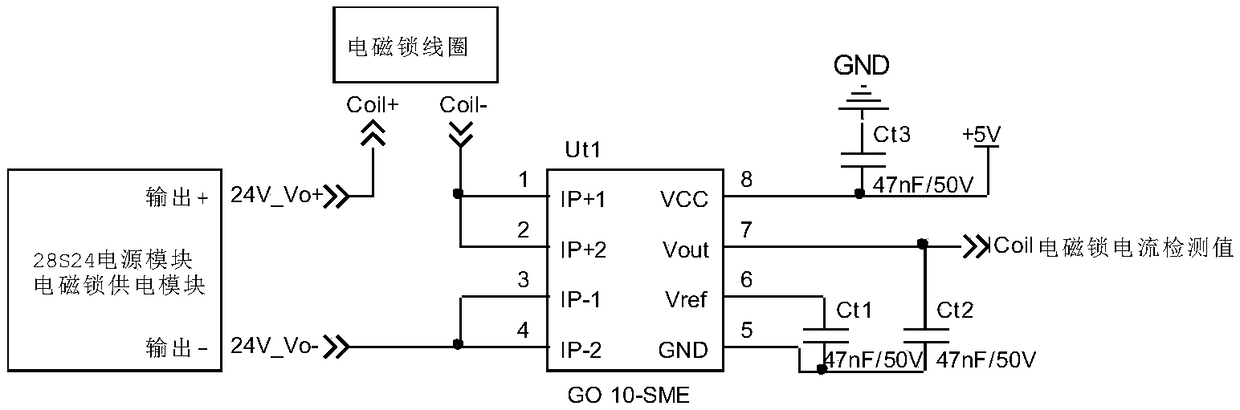

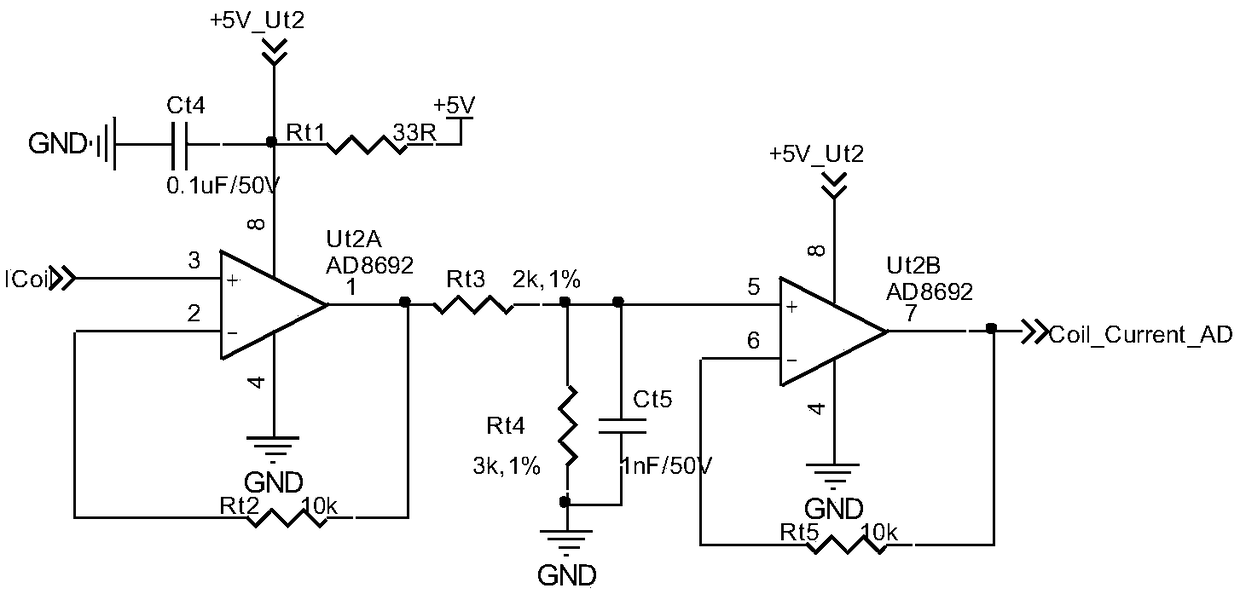

[0035] Embodiment 1: The hardware detection is an electromagnetic lock coil operating current detection circuit based on Hall detection, including a coil current detection circuit in the electromagnetic lock and a coil current signal conditioning circuit in the electromagnetic lock, specifically:

[0036] see figure 1 , the coil current detection circuit in the electromagnetic lock includes: an electromagnetic lock power supply module, an electromagnetic lock coil, and a current sensor, wherein the output end of the electromagnetic lock power supply module is connected to the input end of the electromagnetic lock coil, and the output end of the electromagnetic lock coil is connected to the current sensor , the output terminal of the electromagnetic lock power supply module is also connected to the current sensor, and the current sensor outputs the current detection value of the electromagnetic lock. Wherein, the current sensor is the GO 10-SME current sensor of LEM Company. Wh...

Embodiment 2

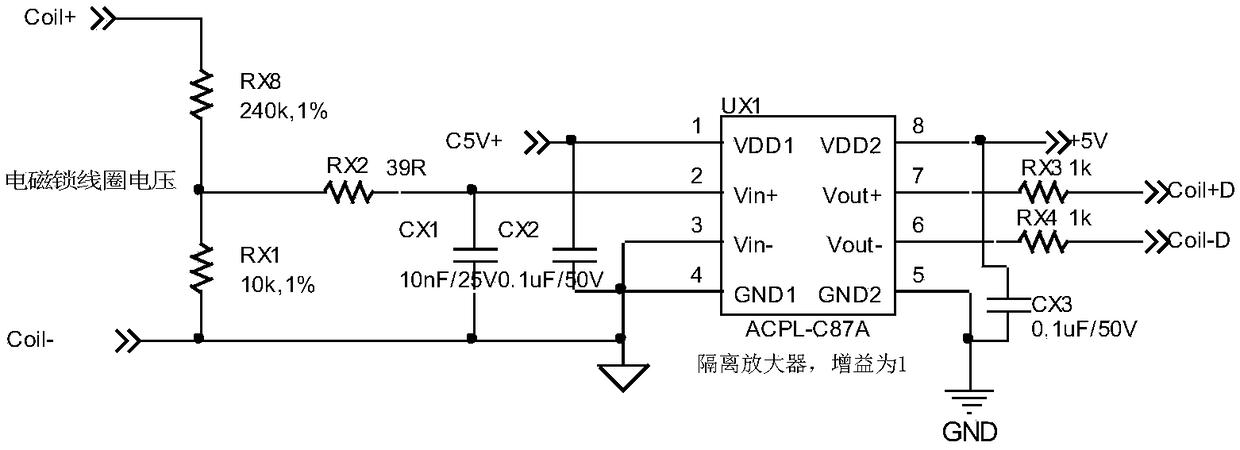

[0038] Embodiment 2: The hardware detection is an isolated electromagnetic lock coil operating voltage detection circuit based on voltage optical isolation acquisition, including a voltage isolation acquisition circuit, an instrument amplifier circuit, and an isolated power supply circuit. specific:

[0039] see image 3 , The voltage isolation acquisition circuit isolates the electromagnetic lock power supply circuit as the primary side from the electromagnetic lock power supply voltage acquisition circuit as the secondary side, and the ratio of the input voltage of the primary side to the output voltage of the secondary side is 1. The voltage isolation acquisition circuit includes an optical isolation amplifier, which includes a sigma-delta AD converter, an optocoupler and a sigma-delta DA converter, and the optical isolation amplifier converts the primary side input analog signal into a digital signal It is transmitted to the secondary side through the optocoupler to achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com