Motor and its control method

A shell and stator technology, applied in the field of motor and its control, can solve the problem that the motor cannot drive the load to run, and achieve the effect of ensuring performance, ensuring rationality, and slowing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

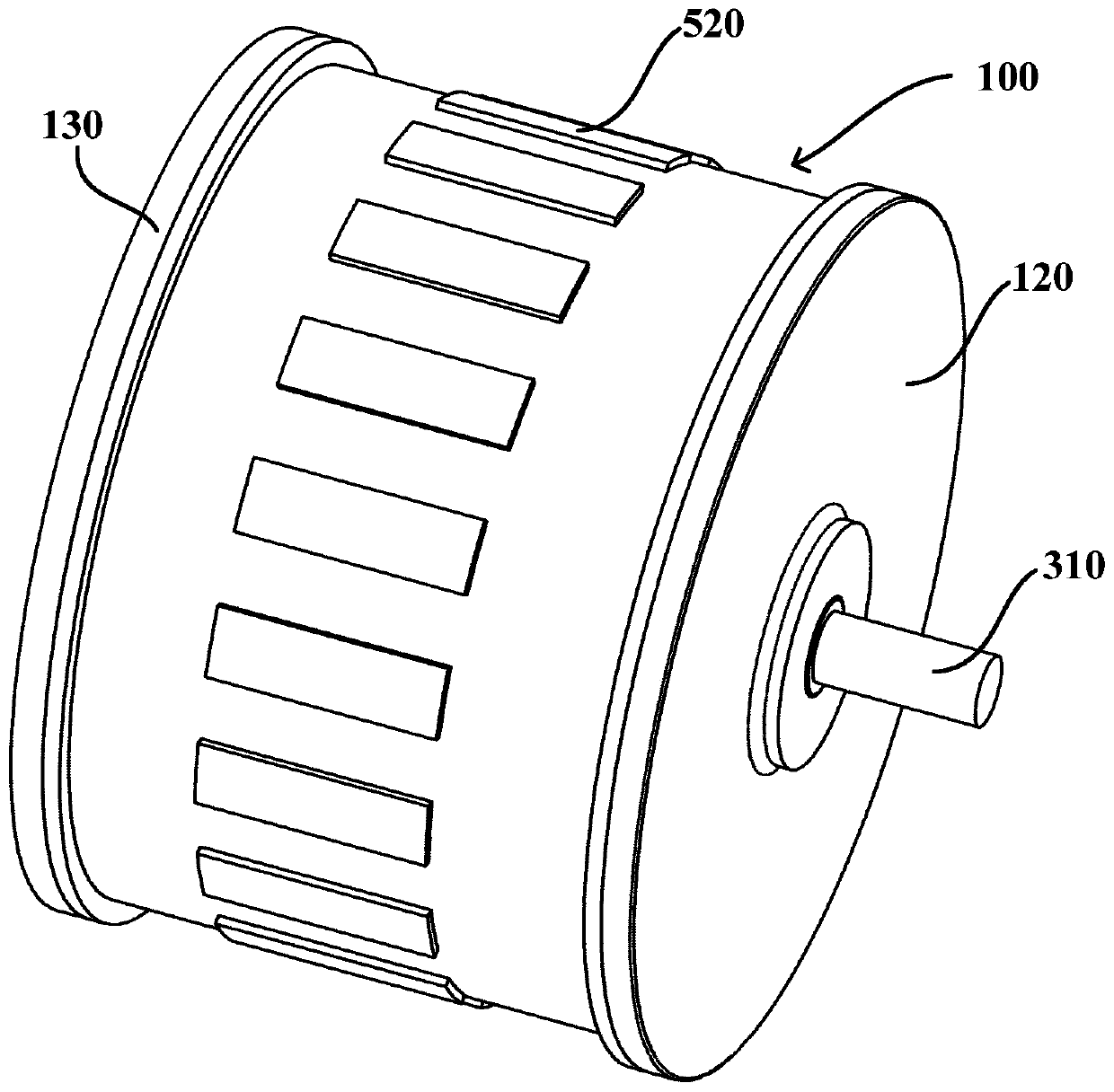

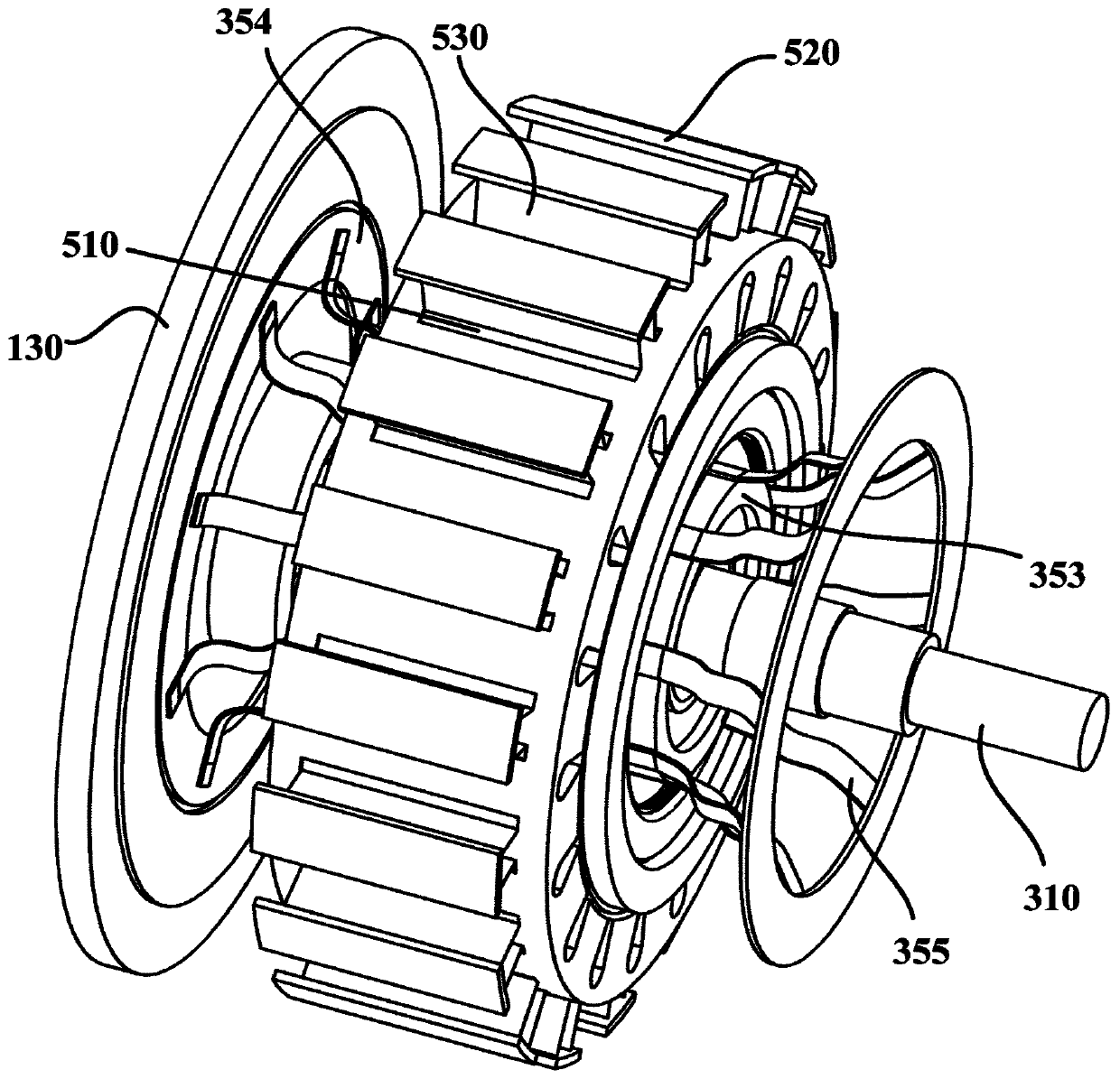

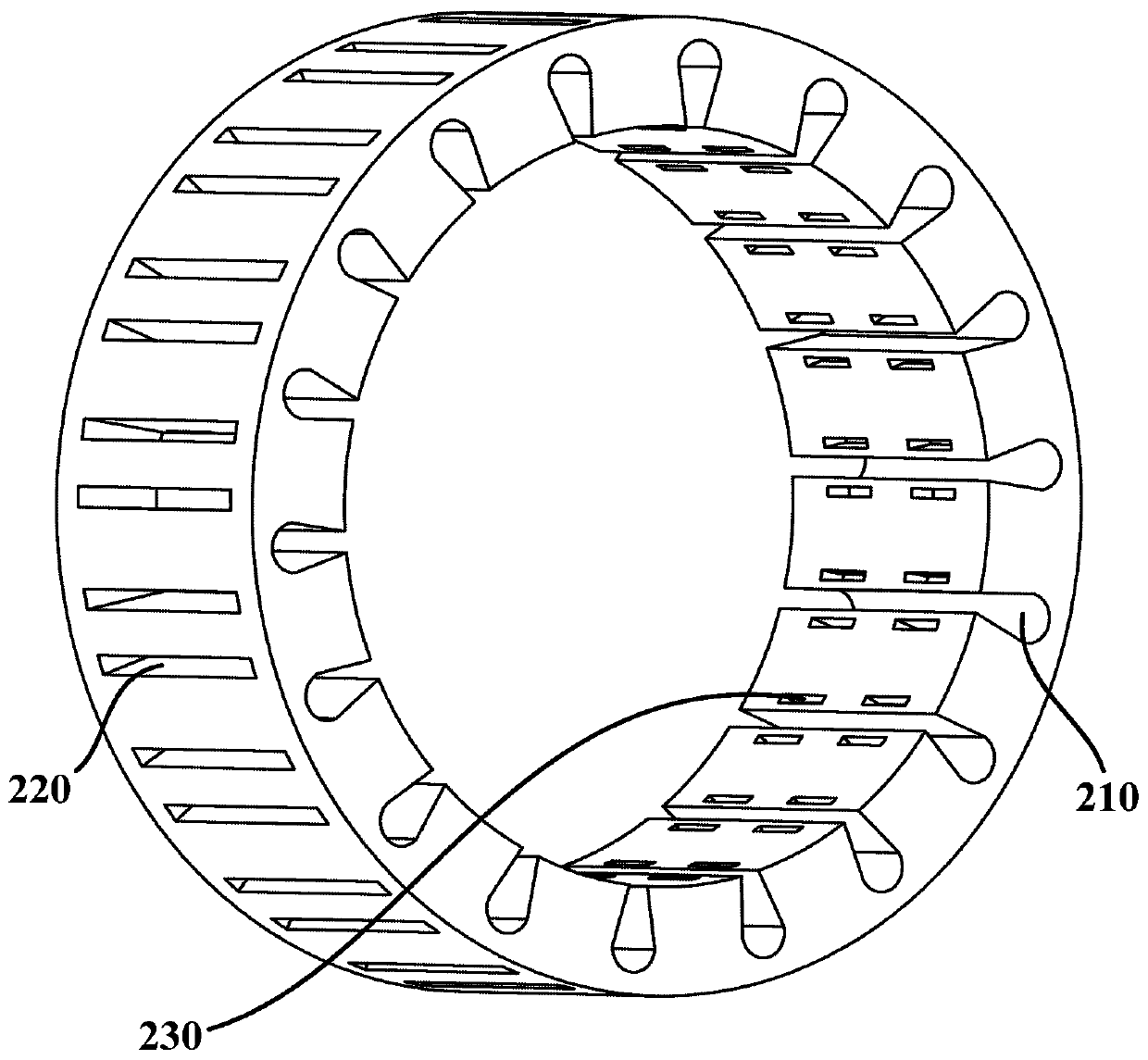

[0050] figure 1 is a schematic structural diagram of a motor according to an embodiment of the present invention. Such as figure 1 shown, and refer to Figure 2 to Figure 12 , the embodiment of the present invention provides a motor. Generally, the motor may include a housing 100 , a stator 200 and a rotor 300 . The housing 100 generally has a main housing 110 and end covers disposed on two ends of the main housing 110 , such as a housing front cover 120 and a housing rear end cover 130 . The stator 200 is disposed in the housing 100 . The rotor 300 is disposed radially inside the stator 200 . The iron core of the stator 200 has stator slots 210 for winding windings 240 .

[0051]In some embodiments of the present invention, in order to improve the heat dissipation performance of the motor, the stator 200 also has a plurality of cooling hole groups, and each cooling hole group has two first strip-shaped holes 220 arranged on both sides of a corresponding stator slot 210 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com