Transformer continuous coil spiral transposition structure and manufacturing method thereof

A technology of transformers and coils, applied in coil manufacturing, transformer/inductor coils/windings/connections, transformer/inductor components, etc., can solve problems such as increased load loss, increased coil temperature rise, and accelerated insulation aging speed. , to achieve the effect of reducing the temperature rise of the coil, reducing the circulating current loss, and reducing the circulating current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

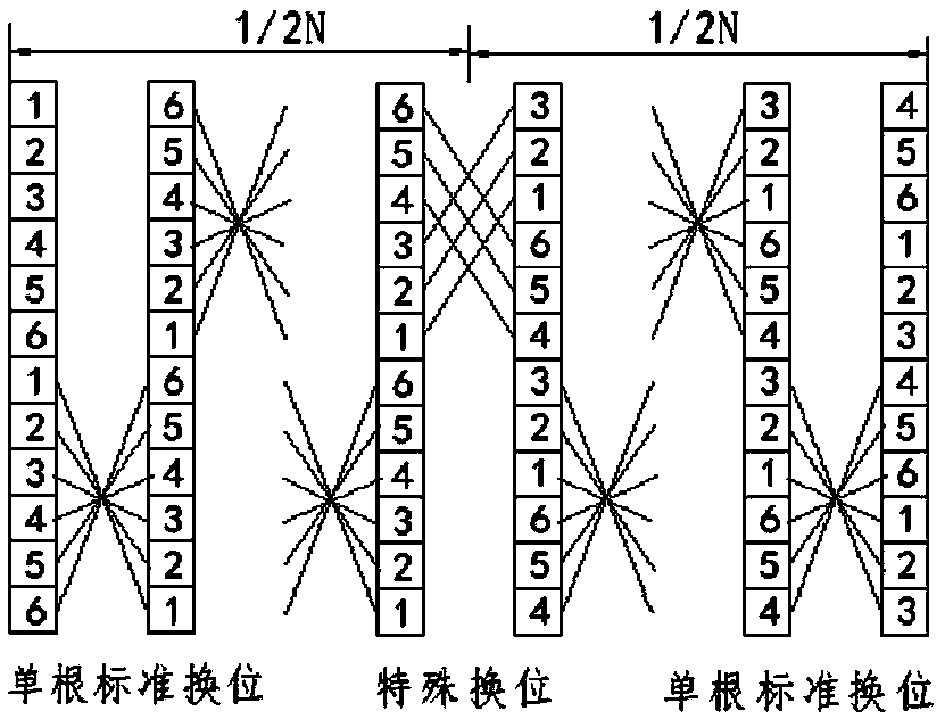

[0015] Embodiment 1: as figure 1 As shown, a transformer continuous coil-like spiral transposition structure includes multi-layer wire cake groups arranged along the coil axis, and each layer of wire cake groups is wound by six wires stacked in the width direction. At least 2 turns of six overlapping wires are wound; a special transposition structure is adopted between two adjacent wire cake groups at half of the coil axis, and a standard transposition structure is adopted between the other two adjacent layers of wire cake groups ; In the special transposition structure, the wires are divided into two groups, that is, a group of three. When transposing, the 3 wires in the upper group and the 3 wires in the bottom group are exchanged for the overall position.

[0016] In this embodiment, the standard transposition structure adopts a single standard transposition structure, and all the wires in the single standard transposition structure are arranged in reverse order when they a...

Embodiment 2

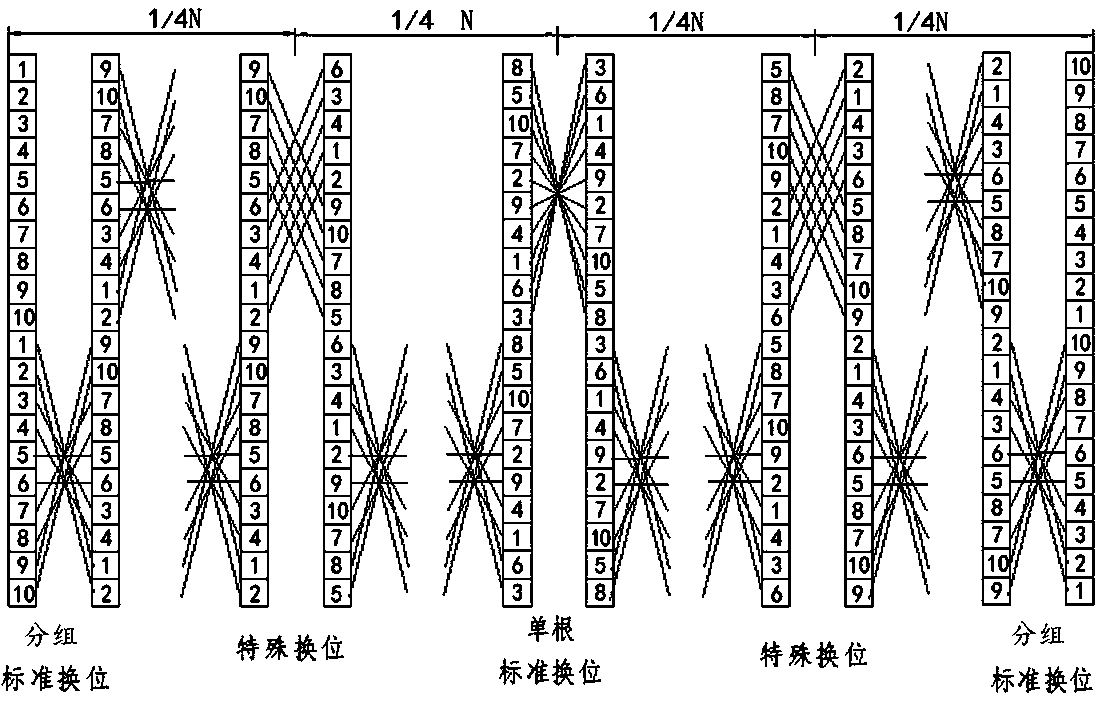

[0019] Embodiment 2: as figure 2 As shown, the number of wires is 10, and a special transposition structure is adopted between the two layers of adjacent wire cake groups at the quarter and three quarters of the coil axis. In the special transposition structure, the conductors are divided into Two groups, that is, a group of five. When transposition, the 5 conductors of the upper group and the 5 conductors of the bottom group are exchanged for the overall position; the other two adjacent layers of wire cake groups adopt a standard transposition structure.

[0020] In this embodiment, the standard transposition structure includes a single standard transposition structure and a grouped standard transposition structure; a single standard transposition structure is adopted between two adjacent wire cake groups at half of the coil axis, The grouping standard transposition structure is adopted between the remaining two adjacent layers of wire cake groups; all conductors in a single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com