Positioning apparatus for LED lamp tube glue coating equipment

A technology for LED lamp tubes and positioning devices, which is applied to devices for coating liquid on the surface, lighting devices, lighting and heating equipment, etc. It can solve the problems that affect the stability of product quality, increase the workload, and be difficult to remove, and achieve stability. The effect of improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

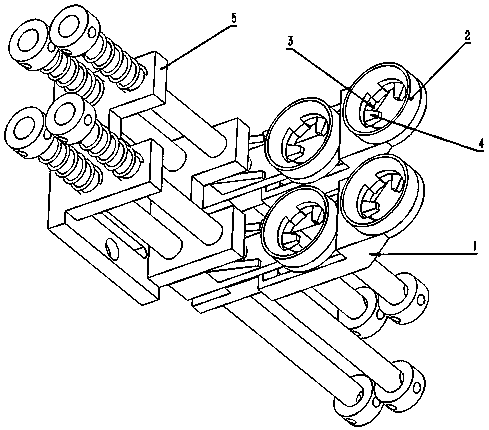

[0009] figure 1 Shown: There are several detachable lamp tube snap rings 2 above the bracket 1 that can be fixed in the middle of the positioning seat 5 of the lower station for glue application, and there are glue discharge holes 3 at the rear of each lamp snap ring 2, distributed around There are three barriers 4. The lamp tube snap ring 2 is an annular structure, and the inner diameter of the rear part of the snap ring is 1-3mm smaller than the inner diameter of the front part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com