Shock absorber for supporting wheel train

A technology of shock absorbing device and supporting wheel, which is used in transportation and packaging, tracked vehicles, motor vehicles, etc., can solve the problems of inability to meet the requirements of developing small track-driven vehicles for fast running, unsatisfactory shock absorption effect, and large volume of parts. , to achieve the effect of convenient loading and unloading, compact structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

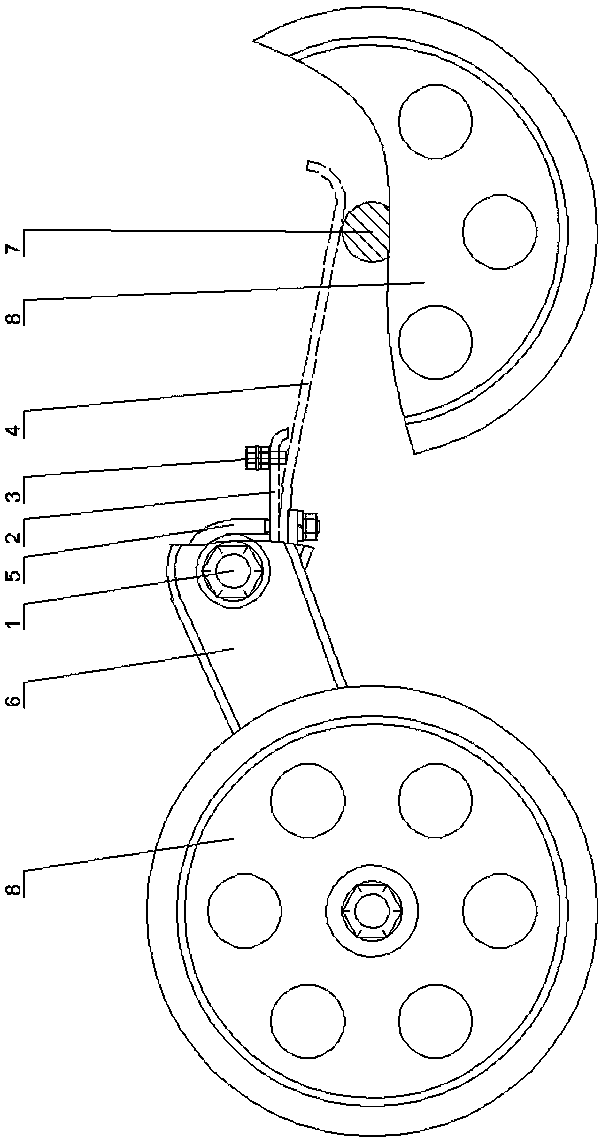

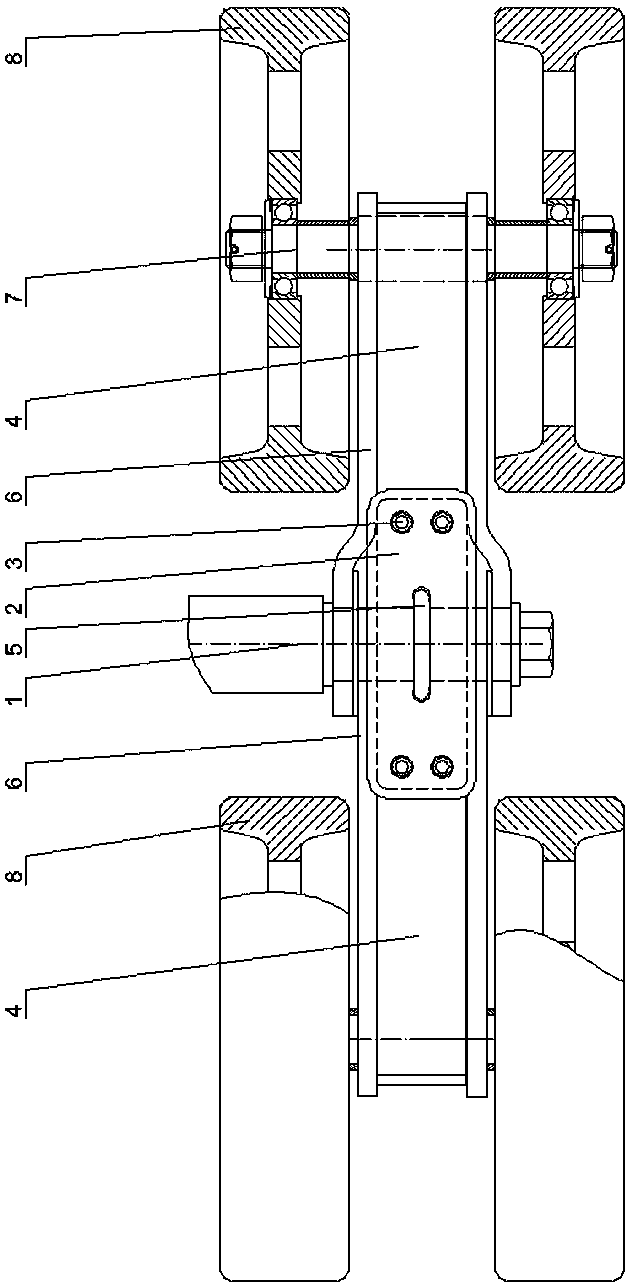

[0017] Depend on figure 1 and figure 2 It can be seen that the present invention includes a central shaft 1, a pressing plate 2, an adjusting bolt 3, a spring steel plate 4, a U-shaped bolt 5, a swing arm 6, a support wheel shaft 7 and a support wheel 8, wherein the two ends of the spring steel plate 4 are respectively pressed on the support wheel in an orderly manner. On the wheel axle 7, it can effectively and significantly alleviate and alleviate the vibration brought by the uneven road surface to the vehicle.

[0018] Depend on figure 1 and figure 2 It is also known that in order to realize the positioning and fastening of the pressure plate 2 and the spring steel plate 4 on the central axis 1, two corresponding holes for the passage of the U-shaped bolt 5 are provided in an orderly manner on the pressure plate 2 and the spring steel plate 4 respectively. through hole.

[0019] Depend on figure 1 and figure 2 It is also known that the pressure plate 2 and the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com