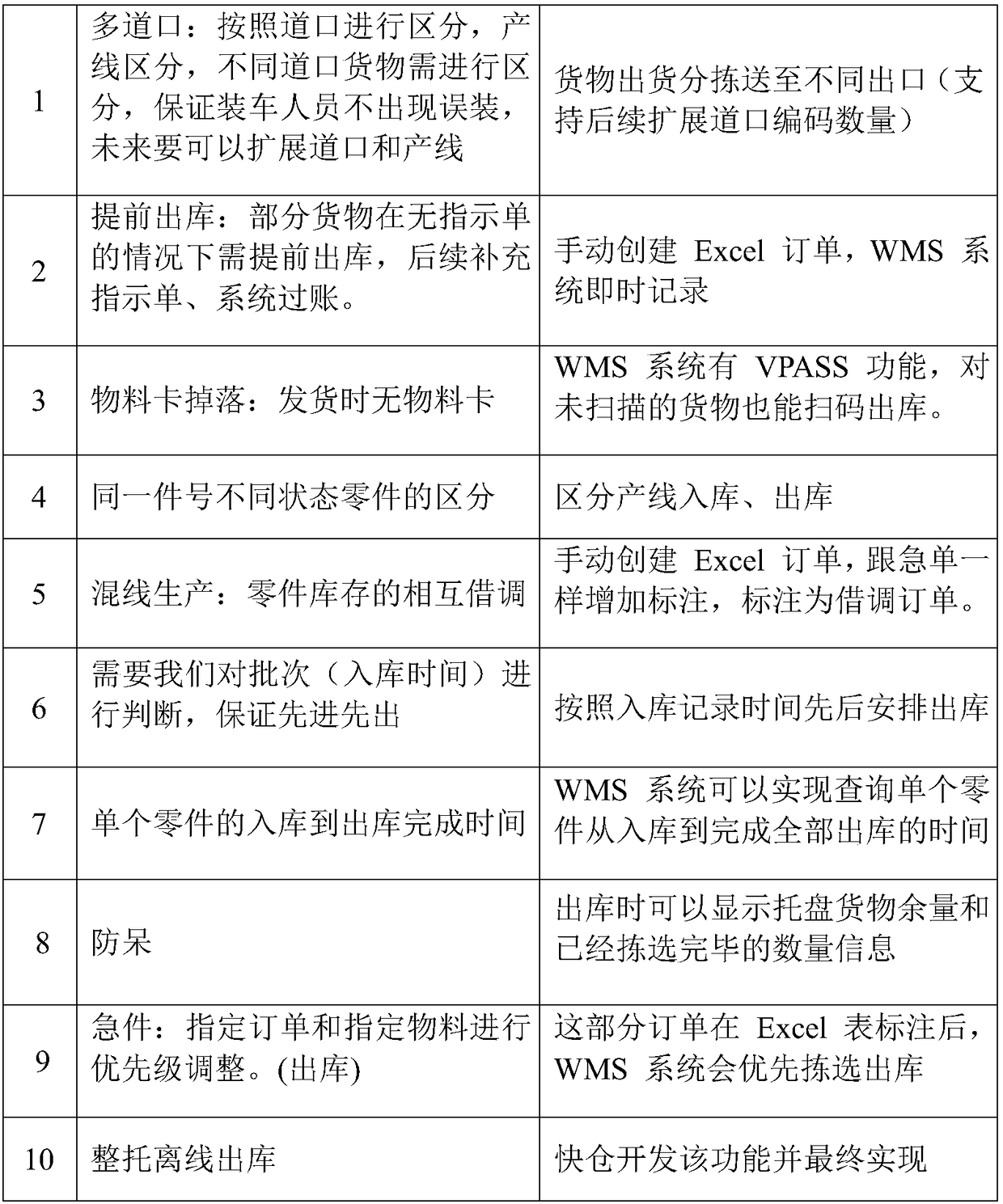

Goods-to-person method for automobile parts

A technology of auto parts and components, applied in the field of logistics and warehousing, can solve problems such as complex operation process, error-prone efficiency, and low efficiency, and achieve the effect of improving sorting efficiency, reducing labor costs, and reducing waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for delivering auto parts to people, the specific steps are as follows:

[0035] Step 1: The customer sends out the warehouse order under the LES system, and the workstation operator logs in to the Kuaicang WMS system, and exports the delivery instruction form Excel form (the file name is order number-crossing number) to the designated order folder (name: delivery instruction Single part schedule), export the order set Excel table (file name is date + serial number) to the specified order folder (name: delivery instruction number summary table).

[0036] Step 2: Kuaicang WMS system reads the files in the specified order folder through ftp and automatically enters the delivery order, and deletes the completed delivery order in the original folder after the operation is completed;

[0037] Step 3: Calculate according to the outbound order, production line, batch, and inventory information, select the whole container outbound process or the whole pallet outbound p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com