Microphone core assembly part conveying mechanism

A conveying mechanism and microphone technology, applied to conveyors, conveyor objects, rotary conveyors, etc., can solve problems such as increasing costs and affecting the quality of finished microphone cores, and achieve the effect of ensuring assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

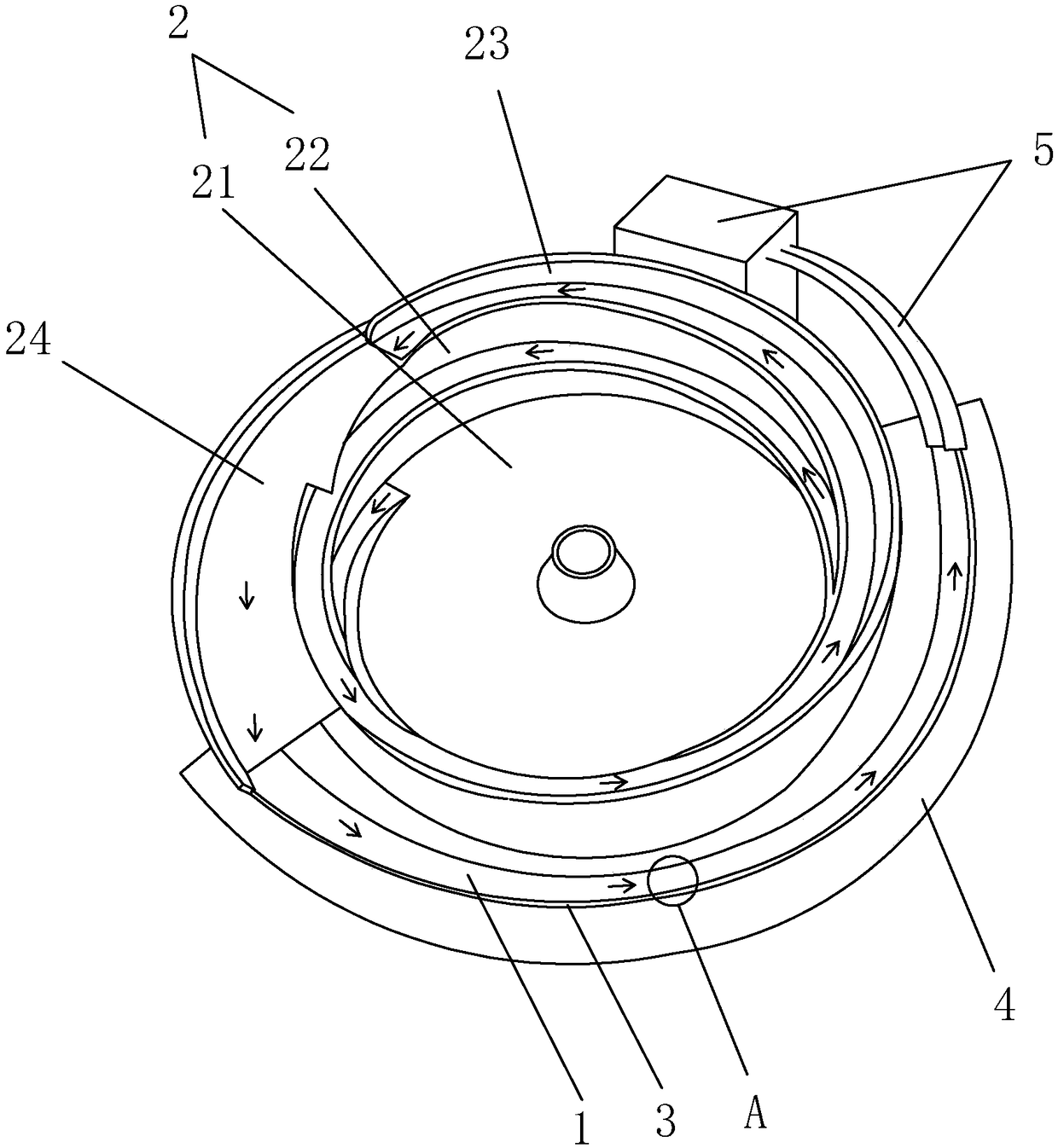

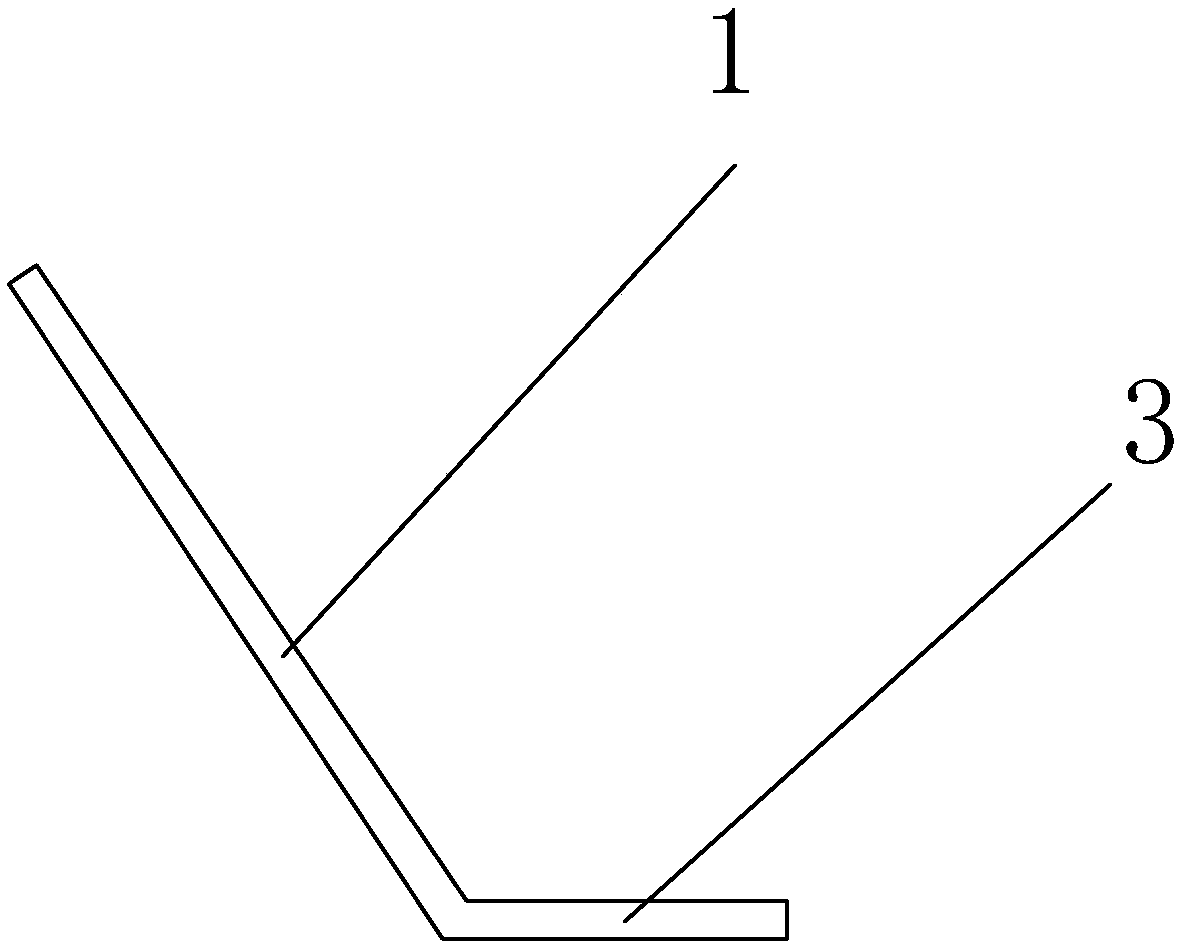

[0015] refer to Figure 1-Figure 2 , a conveying mechanism for microphone core assembly parts of the present invention, including a slope-shaped track 1 for conveying circular metal sheets to microphone core assembly equipment and a spiral conveying device 2 for conveying circular metal sheets to the slope-shaped rail 1 , the bottom of the slope-shaped track 1 is provided with a step 3 for resisting the circular metal sheet to prevent it from falling, the width of the step 3 is greater than or equal to the thickness of one circular metal sheet, and less than the thickness of two circular metal sheets thickness. By setting steps 3 on the slope-shaped track 1, the circular metal sheet can be resisted so that it can be transported on the slope-shaped track 1, and in order to ensure that there are no two pieces of circular metal sheets overlapped and transported together, the step 3, the width of the step 3 is greater than or equal to the thickness of a circular metal sheet, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com