A kind of method utilizing sodium vanadate solution electrolysis to prepare ammonium polyvanadate

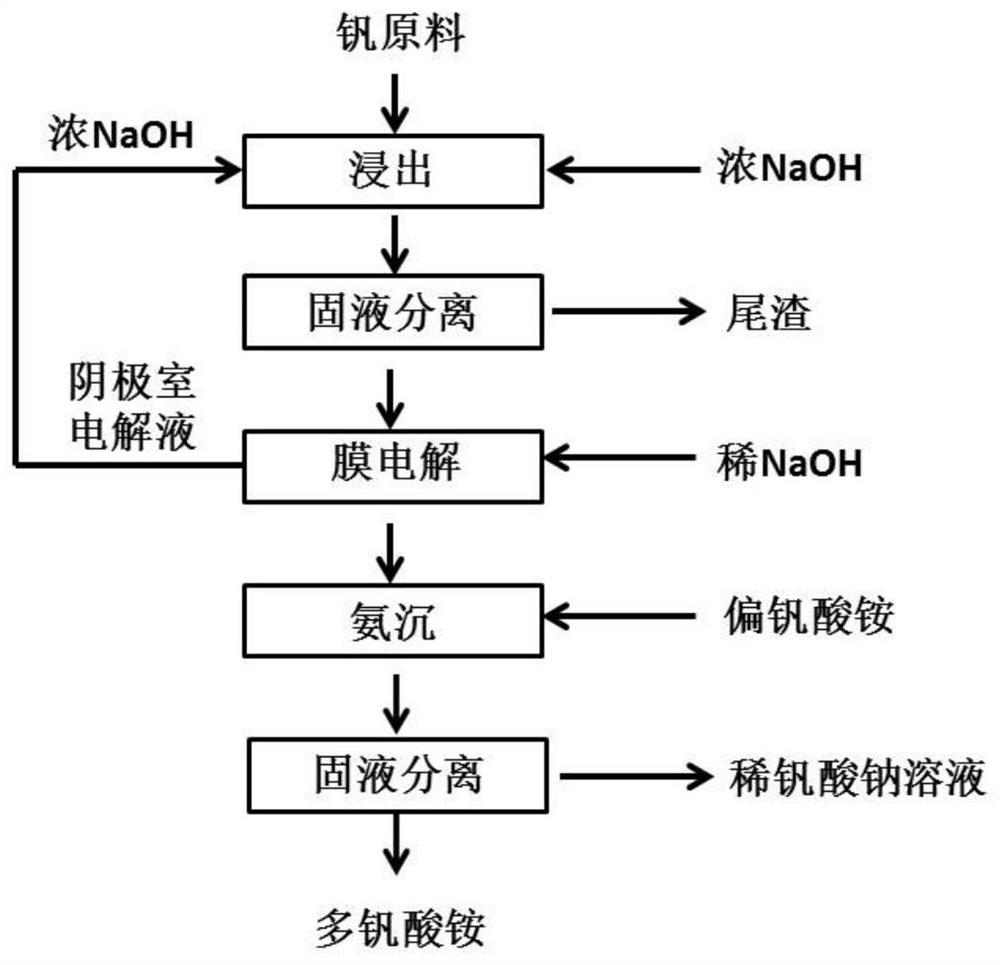

A technology of ammonium polyvanadate and sodium vanadate, applied in electrolysis components, electrolysis process, cells and other directions, can solve the problems of clean production, high production cost and long process flow of unfavorable environmental protection products, and achieve efficient utilization of resources. , easy operation, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) The solution after vanadium slag sodium roasting is used as electrolytic anolyte, the anolyte composition is: Na 81g / L, V 28g / L; catholyte composition: NaOH 60 / L; The anode chamber and cathode chamber of the chamber electrolyzer are electrolyzed, the electrolysis temperature is 30°C, and the current density is 1000A / m 2 , the two chambers are separated by a DuPont N117 cation exchange membrane, and the titanium ruthenium-plated electrode and the Ni electrode are respectively used as the electrolytic anode and cathode;

[0047] (2) After 4 hours of electrolysis, the solution in the anode chamber is transferred out and ammonium metavanadate is added for heating and stirring to control the amount of NH in the ammonium metavanadate 4+ The molar ratio of V in the anode chamber solution is 1:3, and the stirring speed is 300r / min, ammonium polyvanadate crystallizes out rapidly, after the obtained slurry is filtered, the solid phase is dried to obtain the ammonium polyvanad...

Embodiment 2

[0050] (1) Use NaOH solution to directly pressurize the leaching solution of vanadium slag as electrolysis anolyte, anolyte composition: Na79g / L, V 31g / L, catholyte composition: NaOH 90g / L; add anolyte and catholyte respectively The anode chamber and cathode chamber of the three-chamber electrolytic cell are electrolyzed, the electrolysis temperature is 70°C, and the current density is 950A / m 2 , the electrolytic chamber is separated by DuPont 2050 cation exchange membrane, and the ruthenium-plated Ti electrode and Ni electrode are respectively used as electrolytic anode and cathode;

[0051] (2) After 3 hours of electrolysis, return the leached vanadium raw material after the NaOH solution in the cathode chamber is concentrated, transfer the solution in the anode chamber and add ammonium metavanadate for heating and stirring, and control the NH in the ammonium metavanadate 4+ The molar ratio of V in the anode chamber solution is 1:2.5, and the stirring speed is 200r / min. Ammo...

Embodiment 3

[0054] (1) The solution after vanadium-titanium magnetite sodium roasting is used as the electrolytic anolyte, the anolyte composition is: Na 70g / L, V24g / L; the catholyte composition: NaOH 120g / L, the anolyte and the catholyte are respectively Add the anode chamber and cathode chamber of the two-chamber electrolytic cell for electrolysis, the electrolysis temperature is 50°C, and the current density is 900A / m 2 , the electrolysis chamber is separated by Asahi Glass F8080 cation exchange membrane, and the platinum-plated titanium electrode and the carbon steel electrode are respectively used as the electrolysis anode and cathode;

[0055] (2) After electrolysis for 6 hours, the solution in the anode chamber is transferred out and ammonium metavanadate is added for heating and stirring to control the amount of NH in the ammonium metavanadate 4+ The molar ratio of V in the anode chamber solution is 1:1.5, the stirring speed is 100r / min, ammonium polyvanadate crystallizes out rapi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com