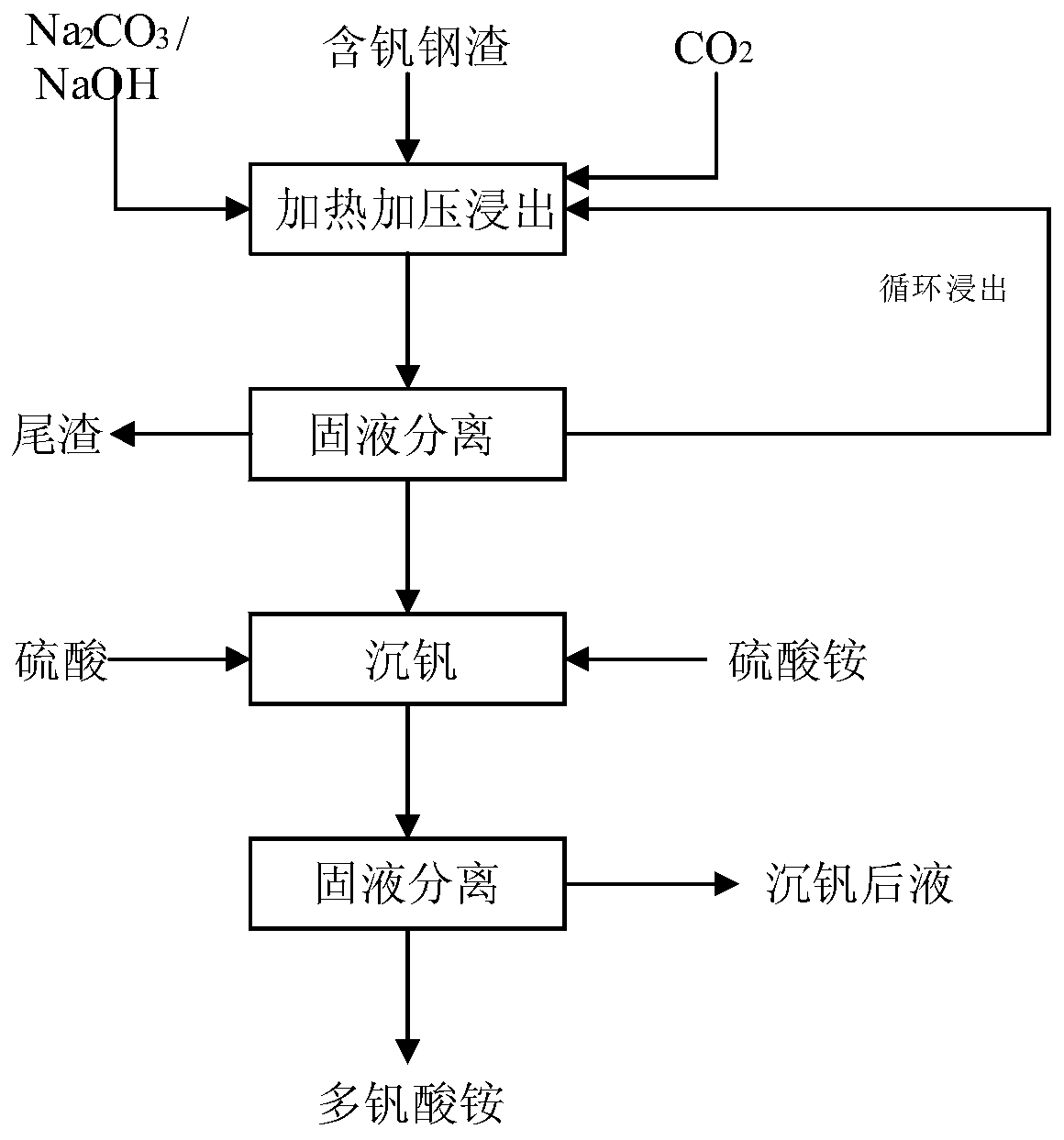

A method for extracting vanadium by carbonization of vanadium-containing steel slag

A technology for steel slag and tailings, which is applied in the field of vanadium extraction by carbonization of vanadium-containing steel slag, can solve the problems of reducing the amount of waste water produced and discharged, high CaO content, reduced product benefit, etc. The effect of efficient vanadium extraction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Put the vanadium-containing steel slag and sodium carbonate solution into the pressure reaction kettle, the concentration of the sodium carbonate solution is 14%, and the liquid-solid ratio of the solution to the vanadium slag is 8:1. Seal the pressurized reactor, feed carbon dioxide gas, and then heat the reaction. The leaching reaction temperature is 100°C, the total pressure of the reactor is 1.2MPa, the partial pressure of carbon dioxide gas is 0.6MPa, and the reaction time is 0.5h. After the reaction, cool down the reaction kettle, open the reaction kettle when the temperature drops to 60°C, filter and separate the mixed slurry to obtain a leaching solution, add sodium carbonate to the leaching solution and circulate it for steel slag leaching, and stop when the concentration of V in the leaching solution reaches 20g / L cycle. According to the molar ratio of ammonium and vanadium 1:2, ammonium sulfate was added to the leaching solution, and at the same time, the pH ...

Embodiment 2

[0044] Put the vanadium-containing steel slag and sodium hydroxide solution into the pressure reaction kettle, the concentration of the sodium hydroxide solution is 15%, and the liquid-solid ratio of the solution to the vanadium slag is 7:1. Seal the pressurized reactor, feed carbon dioxide gas, and then heat the reaction. The leaching reaction temperature is 140°C, the total pressure of the reactor is 1.0MPa, the partial pressure of carbon dioxide gas is 0.4MPa, and the reaction time is 1.5h. After the reaction, cool down the reaction kettle, open the reaction kettle when the temperature drops to 75°C, filter and separate the mixed slurry to obtain a leaching solution, add sodium carbonate to the leaching solution and circulate it for steel slag leaching, until the concentration of V in the leaching solution reaches 23g / L, stop cycle. According to the molar ratio of ammonium and vanadium 1.1:2, ammonium sulfate was added to the leach solution, and the pH value was adjusted to...

Embodiment 3

[0047] Put the vanadium-containing steel slag and sodium carbonate solution into the pressure reaction kettle, the concentration of the sodium carbonate solution is 12%, and the liquid-solid ratio of the solution to the vanadium slag is 6:1. Seal the pressurized reactor, feed carbon dioxide gas, and then heat the reaction. The leaching reaction temperature is 120°C, the total pressure of the reactor is 0.8MPa, the partial pressure of carbon dioxide gas is 0.5MPa, and the reaction time is 1.8h. After the reaction, cool down the reaction kettle, open the reaction kettle when the temperature drops to 60°C, filter and separate the mixed slurry to obtain a leaching solution, add sodium carbonate to the leaching solution and circulate it for steel slag leaching, and stop when the concentration of V in the leaching solution reaches 25g / L cycle. According to the molar ratio of ammonium and vanadium 1.2:2, ammonium sulfate was added to the leach solution, and the pH value was adjusted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com