Long stator power supply section used for maglev train and long stator linear motor

A technology for maglev trains and long stators, which is applied to magnetic circuits, electric components, electric vehicles, etc., can solve the problems of increasing the difficulty of disassembly and rewinding, waste of materials for long stator coils, and serial construction procedures. Short construction period, line repair time, and the effect of improving pavement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

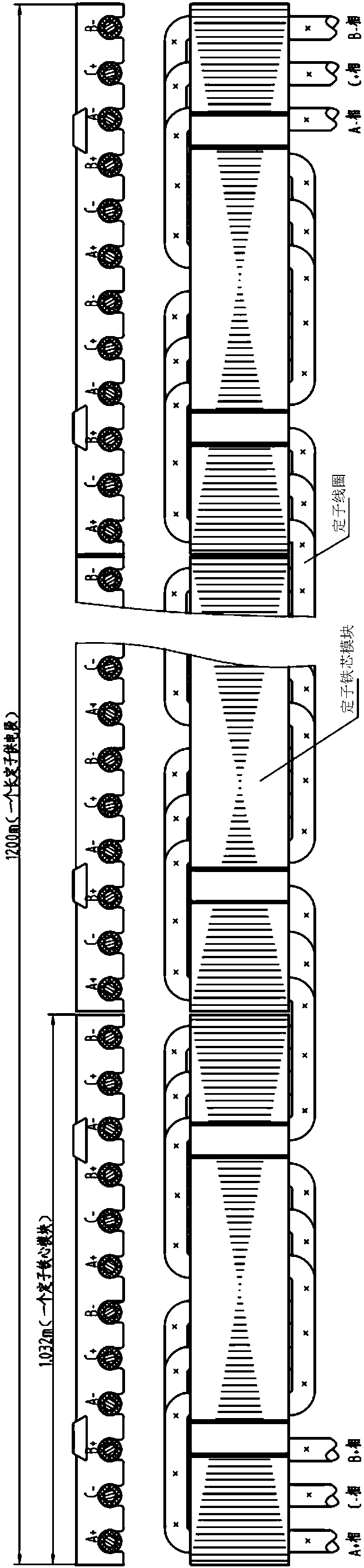

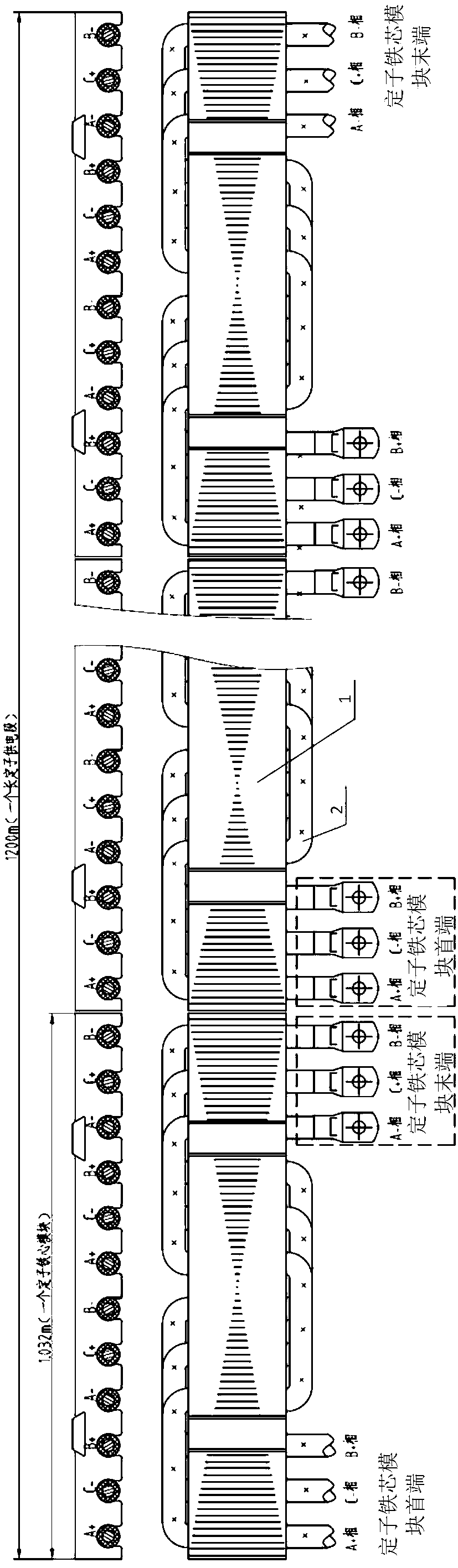

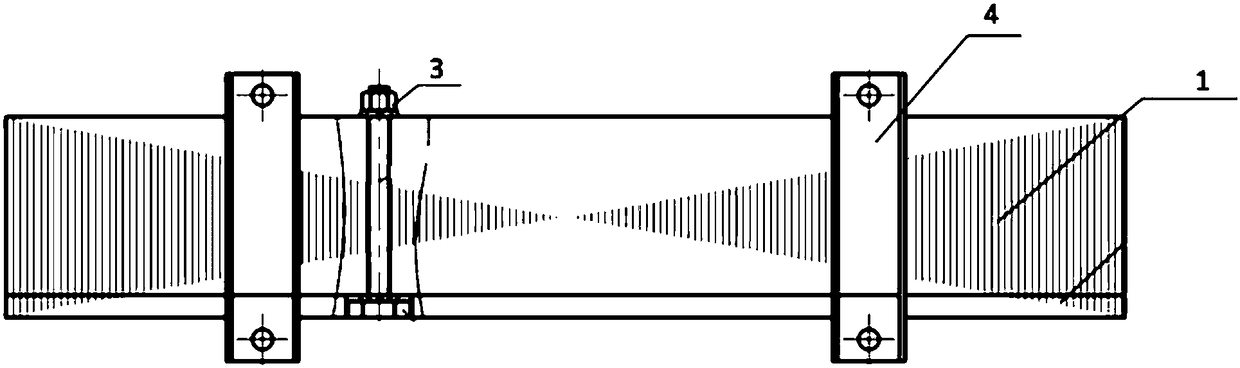

[0026] The core of the present invention is to provide a long stator power supply section and a long stator linear motor for maglev trains. The construction procedures are parallel, which shortens the on-site construction period and improves the paving accuracy of the long stator core on the track beam. Large dedicated winding equipment is required, the cost is low, the difficulty of disassembly and re-embedding is low, the repair time of the line is short, and the waste of stator coils is reduced.

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com